Comprehensive utilization technology used for production of gasoline and liquefied natural gas through methanol synthesis of crushed coal pressure gasification synthetic gas, and used for tar depth processing

A technology for the synthesis of liquefied natural gas and methanol, which is applied in the fields of refining tar through chemical methods, hydroprocessing technology, petroleum industry, etc., and can solve problems such as difficult fuel oil, affecting economic benefits, and poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

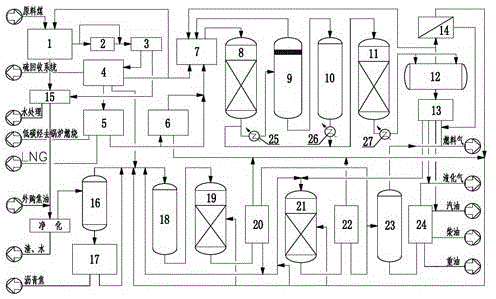

Method used

Image

Examples

Embodiment 1

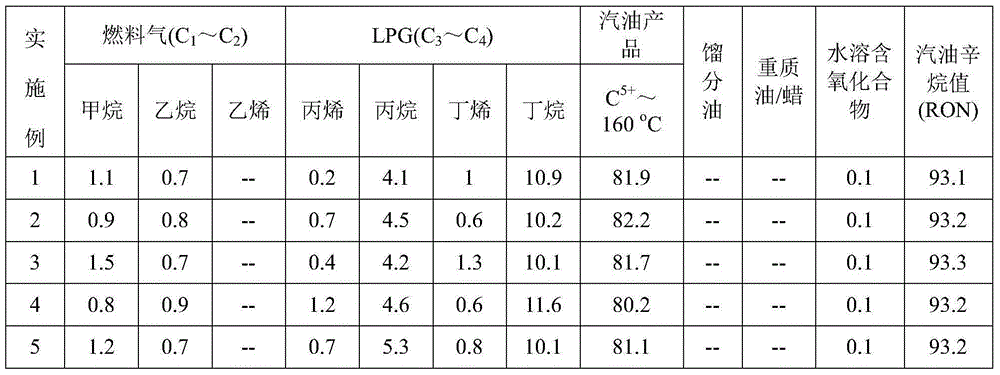

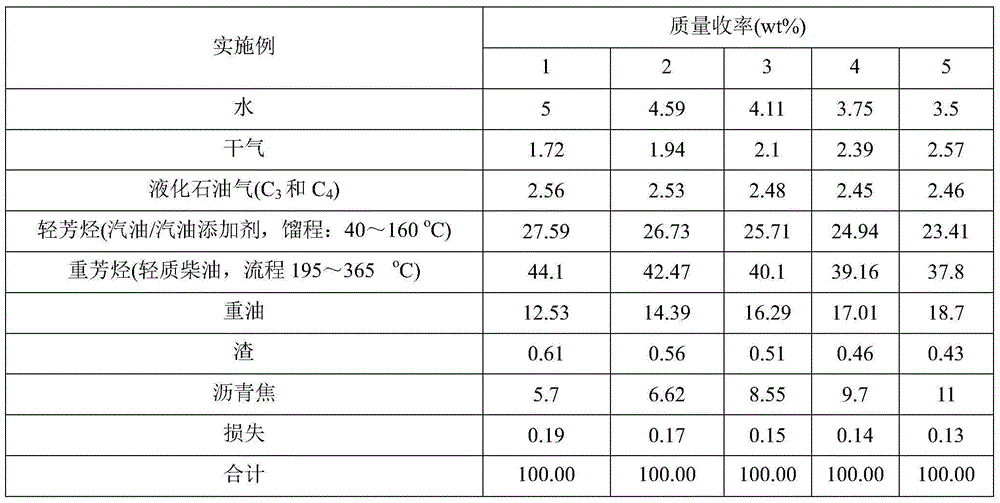

[0061] (1) Raw material lignite is steamed with water vapor: carbon dioxide: oxygen = 8kg: 2m 3 : 1m 3 It is a gasification agent, and it is converted into H through pressurized gasification of crushed coal under the condition of 1400°C and gasification pressure of 4MPa. 2 37%, CO20%, CO 2 33%, CH 4 9.9%, N 20.1% of synthesis gas and tar by-products, 25% of the total volume of synthesis gas in the generated synthesis gas, is produced on the QCS-04 sulfur-resistant shift catalyst produced by Keli Chemical Company of Qilu Petrochemical Research Institute, at a reaction temperature of 460 ° C , the reaction pressure is 6MPa and the gas space velocity is 10000h -1 After the water-vapor shift reaction is carried out under certain conditions, it is mixed with 75% of the side stream syngas into the gas cooling system 3, the condensed oily waste water is sent to the gas-water separation system 15, and the syngas enters the low-temperature methanol washing system 4 , under the con...

Embodiment 2

[0068] In this embodiment, long-flame coal is used as the raw material, and the multi-component gasification agent is composed of water vapor: carbon dioxide: oxygen = 6kg: 3m 3 : 1m 3 , under the condition of 1300℃ and gasification pressure of 4.5MPa, pressurized gasification of pulverized coal is carried out, and the composition of synthesis gas is H 2 40%, CO17%, CO 2 33%, CH 4 9.6%, N 2 0.4%; the generated synthesis gas accounts for 28% of the total volume of the synthesis gas on the QCS-04 sulfur-resistant shift catalyst produced by Keli Chemical Company of Qilu Petrochemical Research Institute. The reaction temperature is 400 ° C, the reaction pressure is 5 MPa and Gas space velocity is 8000h -1 After carrying out the water-vapor shift reaction under certain conditions, 72% of them do not undergo the shift reaction; the low-temperature methanol washing conditions are temperature-50°C and operating pressure 3.8MPa; 6% of the carbon dioxide gas volume removed enters th...

Embodiment 3

[0071] In this embodiment, long-flame coal is used as raw material, and the multi-component gasification agent is composed of water vapor: carbon dioxide: oxygen = 4kg: 4m 3 : 1m 3 , under the condition of 1200℃ and gasification pressure of 5MPa, pressurized gasification of pulverized coal is carried out, and the composition of syngas is H 240%, CO19.9%, CO 2 28%, CH 4 12%, N 2 0.1%; the gas that accounts for 30% of the total volume of the synthesis gas in the generated synthesis gas is used on the QDB-03 sulfur-resistant shift catalyst produced by Qingdao Lianxin Chemical Industry Co., Ltd., at a reaction temperature of 300 ° C, a reaction pressure of 4 MPa and gas Airspeed is 6000h -1 After carrying out the water-vapor shift reaction under certain conditions, and 70% without the shift reaction; the low-temperature methanol washing conditions are temperature-40°C and operating pressure 3.5MPa; 5% of the carbon dioxide gas volume removed enters the synthesis gas compressor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com