GaN-based inverted HEMT device structure and manufacturing method thereof

A device structure and flip-chip technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of poor heat dissipation, low breakdown voltage, and low effective use area of epitaxial wafers, etc., to achieve easy heat dissipation, Effects of improving high-voltage resistance characteristics and improving effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

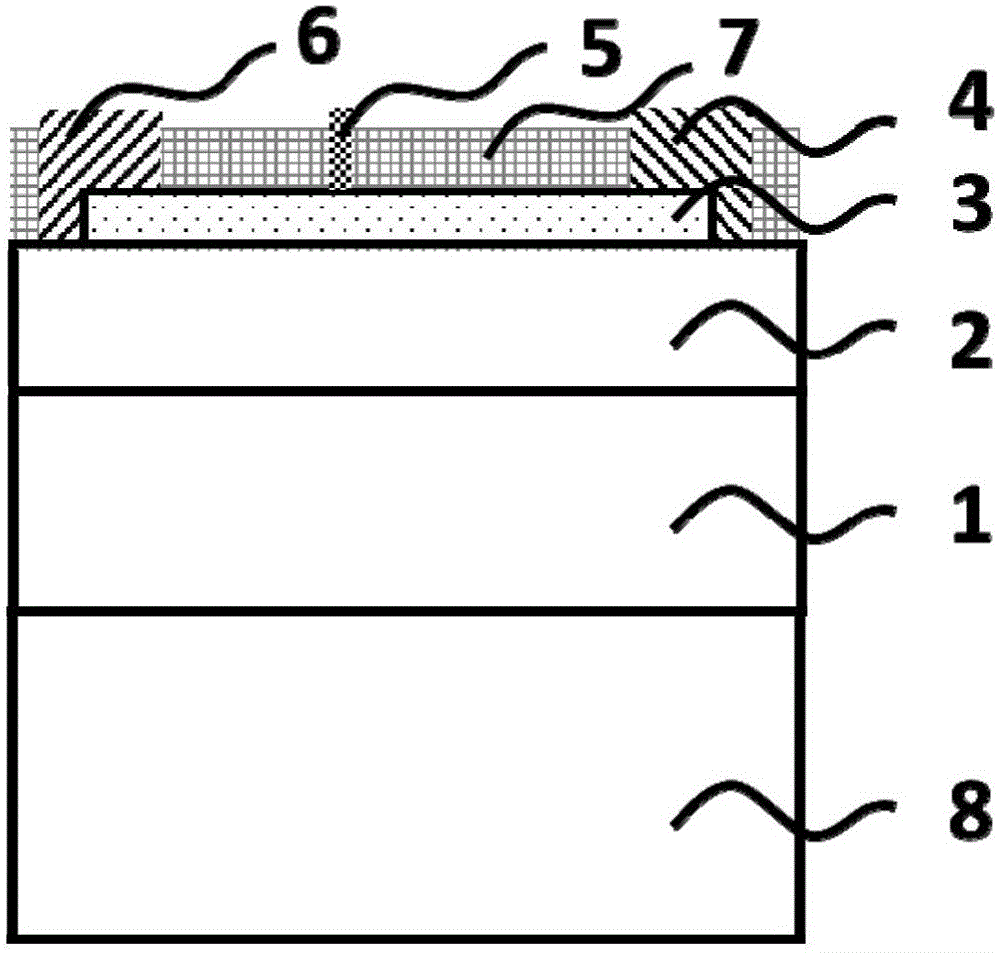

[0045] Example 1, Fabrication of GaN-based flip-chip HEMT

[0046] Such as image 3 As shown, the preparation method steps are as follows:

[0047] (1) Growing a high electron mobility transistor epitaxial layer on a substrate according to the prior art.

[0048] (2) Put the sample of step (1) into boiling acetone for 5 minutes, then into boiling ethanol for 5 minutes, then rinse with deionized water for 5 minutes, and then dry with nitrogen;

[0049] (3) Prepare a mask on the sample surface described in step (2), etch the GaN by inductively coupled plasma (ICP) etching technology, etch the two-dimensional electron gas (2DEG), isolate the mesa, and then remove the mask ;

[0050] (4) After cleaning the surface of the sample described in step (3), deposit Ti / Al / Ti / Au alloy with a thickness of 10 / 300 / 100 / 500nm, and then prepare source and drain electrodes by photolithography technology, and obtain source and drain electrodes after annealing. Leakage ohmic contact;

[0051] (5) After cle...

Embodiment 2

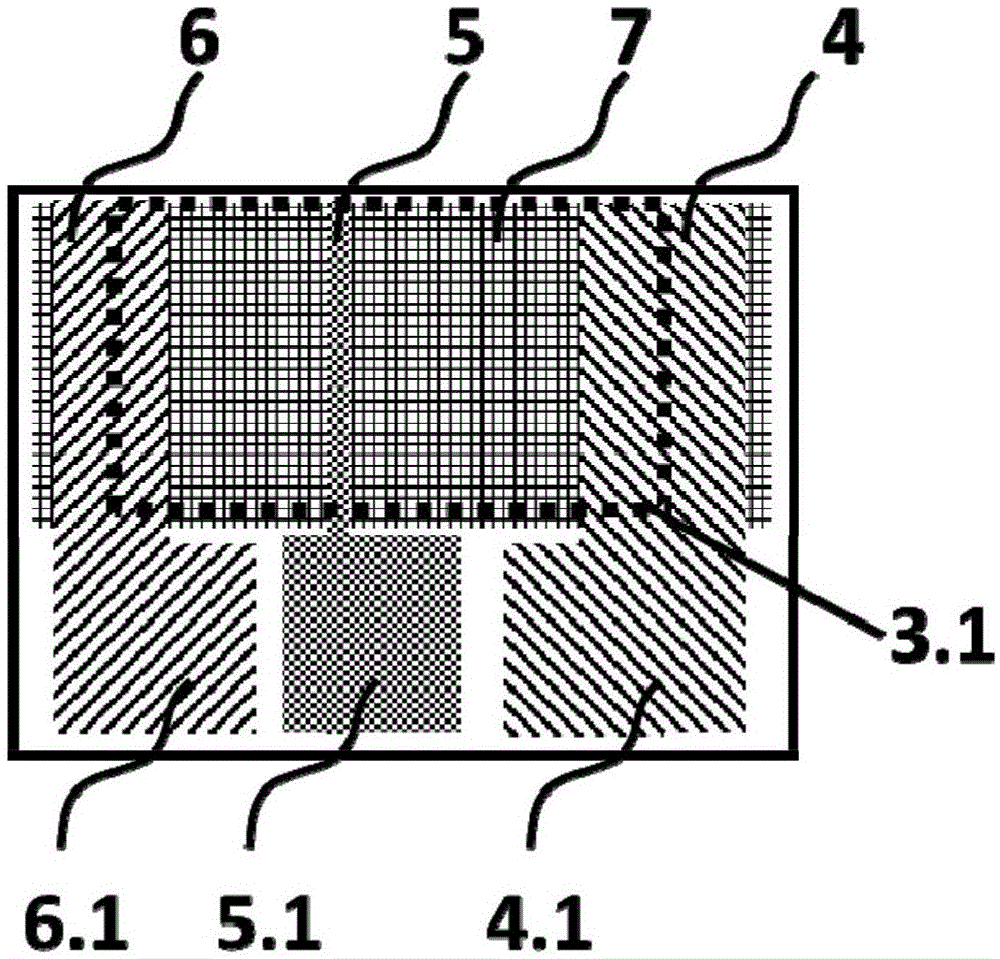

[0060] Example 2, Fabrication of GaN-based flip-chip HEMT

[0061] Such as image 3 As shown, the thin film transistors from bottom to top are 8 substrates, 5.1 gate electrode pads, 5 gate electrodes, 7 insulating dielectric films, 4 drain electrodes, 6 source electrodes, 3AlGaN barrier layers, 2GaN buffer layers, 9 conductive Through holes, 4.1 floor click pads and 6.1 source electrode pads.

[0062] The basic steps of Example 2 are the same as that of Example 1, except that:

[0063] Step (10) completely remove the original substrate of the sample.

[0064] The present invention addresses the problems of poor heat dissipation, low breakdown voltage, and low epitaxial layer utilization of existing transistors, and proposes a flip-chip HEMT structure. After the electrodes are prepared from the epitaxial wafer, it is bonded to the substrate, and then the original liner is thinned and removed. At the bottom, the source and drain electrodes are electrically connected to the pads throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com