A kind of nanostructure quasi-solid electrolyte for lithium-ion battery or lithium-sulfur battery and its preparation method and application

A lithium-ion battery, lithium-sulfur battery technology, applied in solid electrolytes, organic electrolytes, non-aqueous electrolytes, etc., can solve the problems of low safety capacity, poor cycle performance, etc., to ensure no loss, improve conductivity, and improve transmission efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

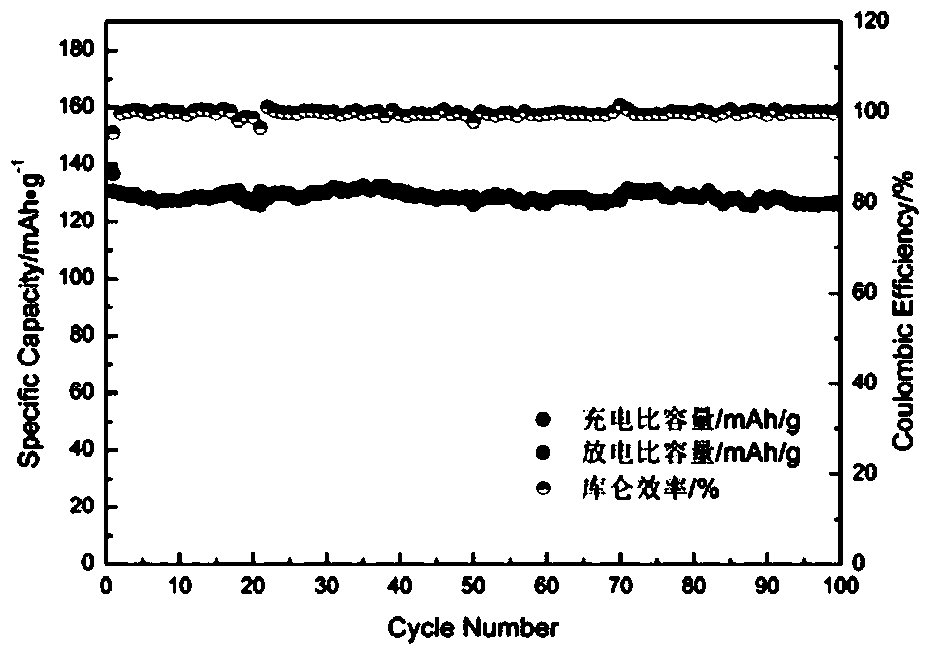

[0036] The preparation component is metal organic framework MIL-53(Al)+EC-DMC-EMC-LiPF 6 Quasi-solid electrolyte, mass ratio 1:3.

[0037] According to technical requirements, MIL-53(Al) was prepared first. Weigh 1.7g of aluminum nitrate hexahydrate and 0.5g of terephthalic acid, add to 25mL of DMF (N,N-dimethylformamide), then add 5mL of deionized water, and heat for 24 hours under the protection of argon to obtain a white After cooling down to room temperature, the powder crystal was impregnated with DMF for 3 times, 50 mL each time, for 12 hours, and then the solvent was evaporated under vacuum at 80°C to obtain MIL-53(Al) white powder. Weigh MIL-53(Al) and EC-DMC-EMC-LiPF 6The electrolyte solution is mixed at a mass ratio of 1:3, placed in a clean glass bottle and stirred for 24 hours, and it becomes a viscous white paste after mixing evenly. Spread the intermediate state electrolyte evenly on the positive electrode sheet, and place it for 8 hours to evaporate the exces...

Embodiment 2

[0039] The prepared components are metal-organic framework MIL-53(Al)+PTFE+EC-DMC-EMC-LiBOB quasi-solid thin film electrolyte with a mass ratio of 1:1.

[0040] According to technical requirements, MIL-53(Al) was prepared first. Weigh 1.7g of aluminum nitrate hexahydrate and 0.5g of terephthalic acid, add to 25mL of DMF (N,N-dimethylformamide), then add 5mL of deionized water, and heat for 24 hours under the protection of argon to obtain a white After cooling down to room temperature, the powder crystal was impregnated with DMF for 3 times, 50 mL each time, for 12 hours, and then the solvent was evaporated under vacuum at 80°C to obtain MIL-53(Al) white powder. Weigh the isopropanol solution of MIL-53(Al) and PTFE and mix them evenly, then use the pair of rollers to press into sheets to make a frame film. Soak the prepared film in EC-DMC-EMC-LiPF 6 After 12 hours in the electrolyte, the excess solvent on the surface was volatilized to prepare an electrolyte film, and its con...

Embodiment 3

[0042] A quasi-solid electrolyte suitable for high-temperature conditions is prepared whose components are metal-organic framework MOF-5+EC-DMC-EMC-PS-LFTSI+3%PAA.

[0043] According to the technical requirements, first synthesize MOF-5, weigh 1.50mmol zinc nitrate hexahydrate and 0.50mmol terephthalic acid, add them to 49mL DMF, then add 1mL deionized water, and heat for 7 hours under the protection of argon to obtain white powder After cooling down to room temperature, it was impregnated with DMF three times, 50 mL each time, for 12 hours, then exchanged and activated with dichloromethane solvent for 3 times, 50 mL each time, 12 hours, and then evaporated the solvent under vacuum at 40 ° C to obtain MOF- 5 white powder. Mix MOF-5, EC-DMC-EMC-PS-LFTSI at a mass ratio of 2:3, and stir it in a glass bottle for 24 hours to form a viscous light yellow paste-like quasi-solid electrolyte, then add 3% wt of PAA, continue to stir until the components are evenly mixed. Place the ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com