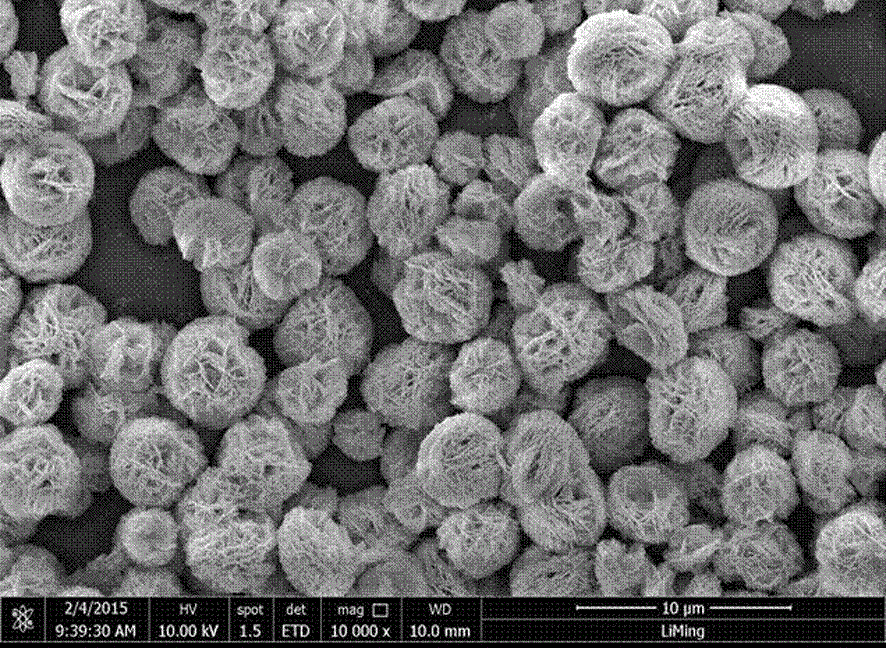

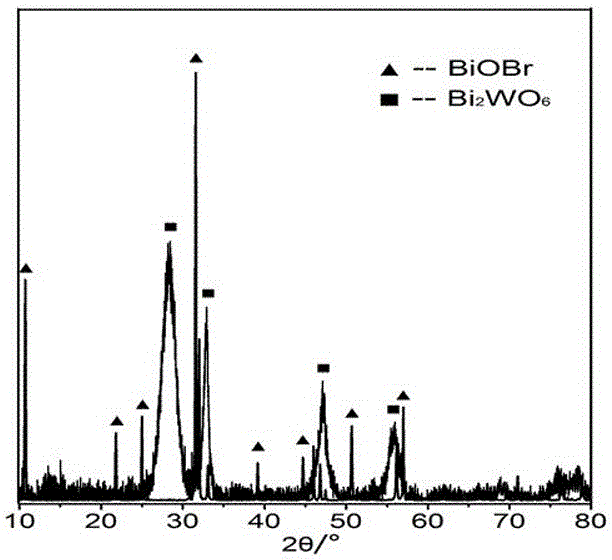

BiOBr/Bi2WO6 composite photocatalyst with heterostructure and preparation method thereof

A technology of heterostructures and catalysts, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of easy recombination of photogenerated carriers and low photocatalytic efficiency, and achieve extended visible light transmission. Path, low preparation cost, favorable for efficient generation and delayed recombination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Its preparation method comprises the following steps:

[0023] 1. Preparation of the premixed system: at room temperature, 1.0-3.0 mmol of Bi(NO 3 ) 3 ·5H 2 Add O into 20-50mL of dilute nitric acid solution, stir to dissolve it completely, and obtain a colorless and transparent bismuth nitrate solution A; - and tungstate WO 4 2- The molar ratio is 1 : (1-1.5) ratio, respectively weigh soluble bromide and tungstate, dissolve in 50-100mL water successively, stir, and obtain the - and WO 4 2- The mixed solution, and then add surfactant and fatty alcohol, so that the concentration of the two in the solution reaches 0.01-0.1mol L -1 , after stirring evenly, the mixed solution B is obtained; at room temperature, through strong magnetic stirring, the mixed solution B is slowly added dropwise to the A solution to obtain a suspension premixed system C containing light yellow insoluble matter, which is allowed to stand for 0.5 -2.0 hours;

[0024]2. Preparation of compo...

Embodiment 1

[0031] At room temperature, weigh 1.0mmolBi(NO 3 ) 3 ·5H 2 O dissolved in 20mL has a molar concentration of 1.0mol L -1 HNO 3 solution, stirred to obtain a colorless and transparent A solution; respectively take 1.0mmolNaBr and 1.0mmolNa 2 WO 4 2H 2 O, dissolved in 50mL of water successively, after stirring constantly, then add sodium lauryl sulfate and 0.5mmol of butanol respectively, to obtain mixed solution B. Under strong magnetic stirring, slowly drop the mixed solution B into the solution A to obtain a suspension C containing a light yellow precipitate, and let it stand for 0.5h; ultrasonically treat the suspension C for 30min, and transfer it to a 50mL polytetrafluoroethylene-lined In the water heating kettle, use 1.0mol·L -1 HNO 3 or 0.5mol·L -1 Adjust the pH value of the reaction system in the kettle to 3 with NaOH, so that the filling degree in the kettle is 60%, seal the kettle, and place it in a thermostat at 140°C for 15 hours; after the reaction, centrif...

Embodiment 2

[0033] At room temperature, weigh 3.0mmolBi(NO 3 ) 3 ·5H 2 O dissolved in 50mL has a molar concentration of 5.0mol L -1 HNO 3 solution, after fully stirring, a colorless and transparent solution of A was obtained; respectively take 1.0mmol NH 4 Br and 1.5mmol (NH 4 ) 6 W 7 o 24 ·6H 2 O, dissolved in 100mL of water successively, under continuous stirring, then add 10.0mmol each of alkylphenol polyoxyethylene ether and ethylene glycol respectively to obtain mixed solution B. Under strong magnetic stirring, slowly add the mixed liquid B to the A solution dropwise to obtain a suspension C containing a light yellow precipitate, and let it stand for 2.0h; ultrasonically treat the suspension C for 30min, and transfer it to a 50mL liner lined with polytetrafluoroethylene In the hydrothermal kettle, use 5.0mol·L -1 HNO 3 or 3.0mol·L -1 Adjust the pH value of the reaction system in the kettle to 9 with NaOH, so that the filling degree in the kettle is 80%, seal the kettle, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com