A polyolefin polymer barrier explosion-proof material and its preparation method

A technology of barrier explosion-proof materials and polyolefins, which is applied in the field of preparation of polyolefin polymer barrier explosion-proof materials, can solve problems such as difficult recycling, oil quality pollution, and complex molding process of non-metallic thermosetting polyurethane foam explosion-proof materials. Achieve low price, low production cost, and overcome the effect of easy corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

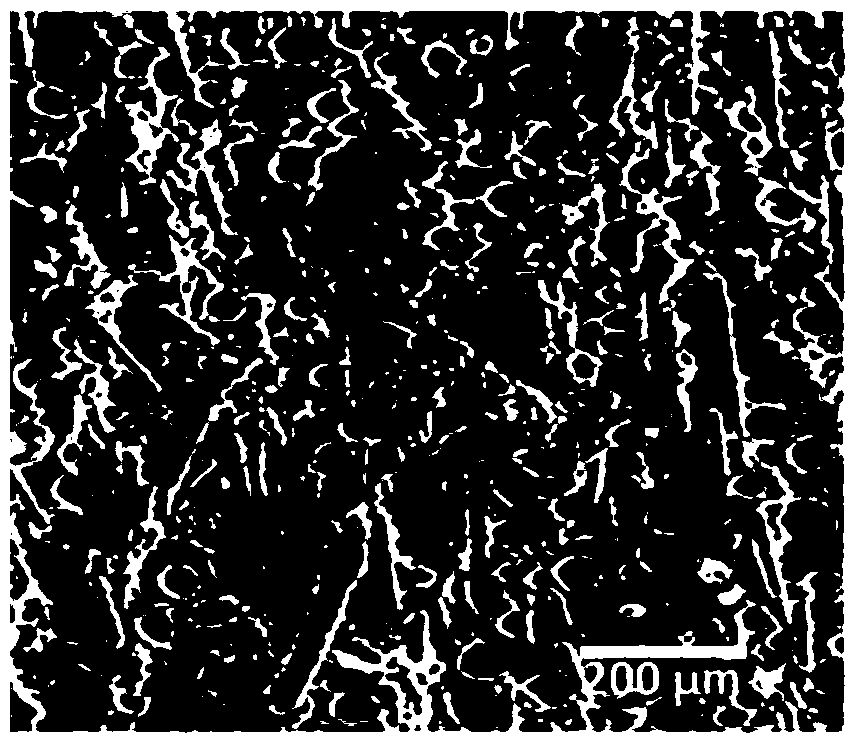

Image

Examples

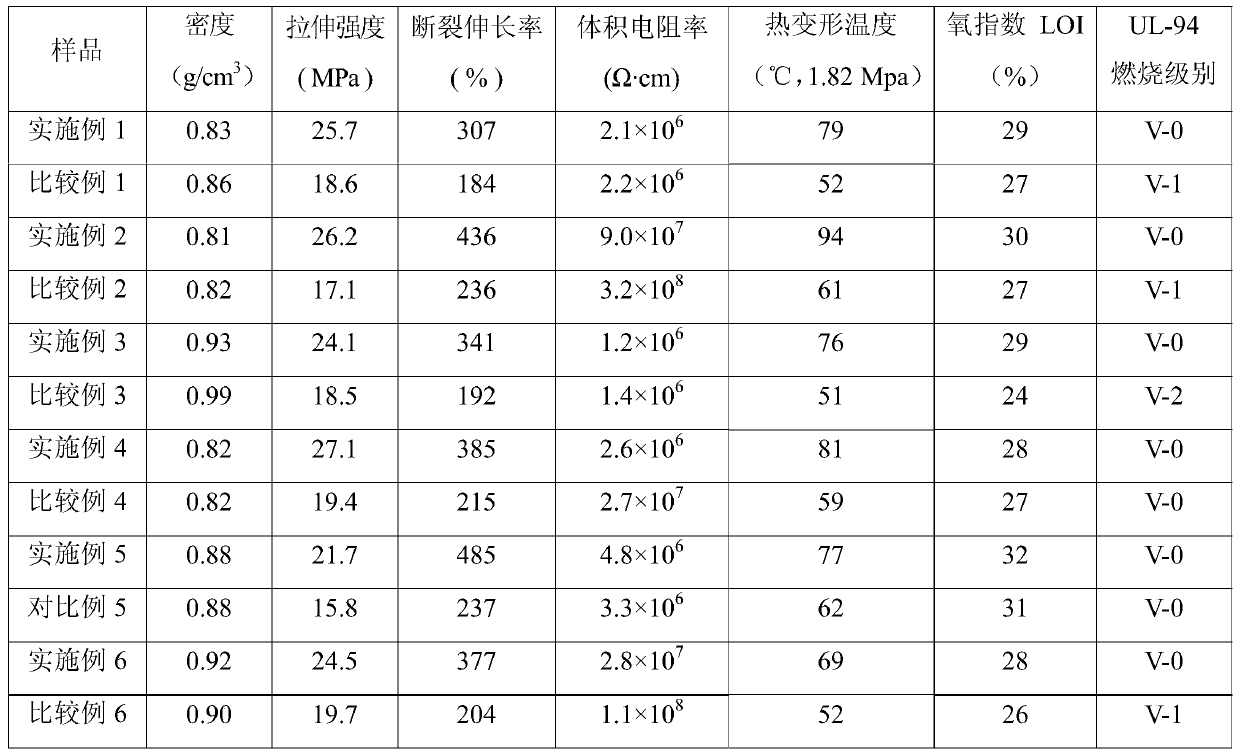

Embodiment 1

[0030] The mass parts array of raw materials is: 80 parts of polyethylene, 20 parts of flame retardant (decabromodiphenyl ether and antimony trioxide mixture, mass ratio 2:1), 15 parts of conductive carbon black, 3.5 parts of foaming agent, nucleating 1.2 parts of nano-calcium carbonate, 5 parts of toughening agent, 2.5 parts of flame-retardant plasticizer phosphate, antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate ] 2.5 parts of pentaerythritol esters.

[0031] The raw materials of the above formula are fully dried and mixed evenly in a high-speed mixer according to the proportion. Use Zhoushan Tongfa Machinery Manufacturing Co., Ltd. SJSZ-25 co-rotating conical twin-screw extruder (screw diameter 25mm, compression ratio 1:10), set the temperature at 180-220°C, screw speed 200 rpm, and extrude Granulate. After the obtained pellets were fully dried, they were molded into standard splines with an injection molding machine, and tested for mechanical prope...

Embodiment 2

[0035] The mass parts array of raw materials is: 80 parts of polypropylene, 25 parts of flame retardant (a mixture of decabromodiphenyl ether and antimony trioxide, mass ratio 2:1), 10 parts of conductive carbon black, 3.8 parts of foaming agent, nucleating 1.5 parts of nano-attapulgite, 10 parts of toughening agent, 2.5 parts of flame-retardant plasticizer phosphate, antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid Esters] 2.5 parts of pentaerythritol esters.

[0036] The raw materials of the above formula are fully dried and mixed evenly in a high-speed mixer according to the proportion. Use Zhoushan Tongfa Machinery Manufacturing Co., Ltd. SJSZ-25 co-rotating conical twin-screw extruder (screw diameter 25mm, compression ratio 1:10), set the temperature at 220-260°C, screw speed 200 rpm, and extrude Granulate. After the obtained pellets were fully dried, they were molded into standard splines with an injection molding machine, and tested for mecha...

Embodiment 3

[0040] The mass parts array of raw materials is: 80 parts of polystyrene, 20 parts of flame retardant (decabromodiphenyl ether and antimony trioxide mixture, mass ratio 2:1), 15 parts of conductive carbon black, 3.8 parts of foaming agent, the composition 1.6 parts of nuclear agent nano-montmorillonite, 5 parts of toughening agent, 1 part of flame-retardant plasticizer phosphate, antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propane Ester] 1 part of pentaerythritol ester.

[0041] The raw materials of the above formula are fully dried and mixed evenly in a high-speed mixer according to the proportion. Use Zhoushan Tongfa Machinery Manufacturing Co., Ltd. SJSZ-25 co-rotating conical twin-screw extruder (screw diameter 25mm, compression ratio 1:10), set the temperature at 150-220°C, screw speed 200 rpm, and extrude Granulate. After the obtained pellets were fully dried, they were molded into standard splines with an injection molding machine, and tested for mecha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com