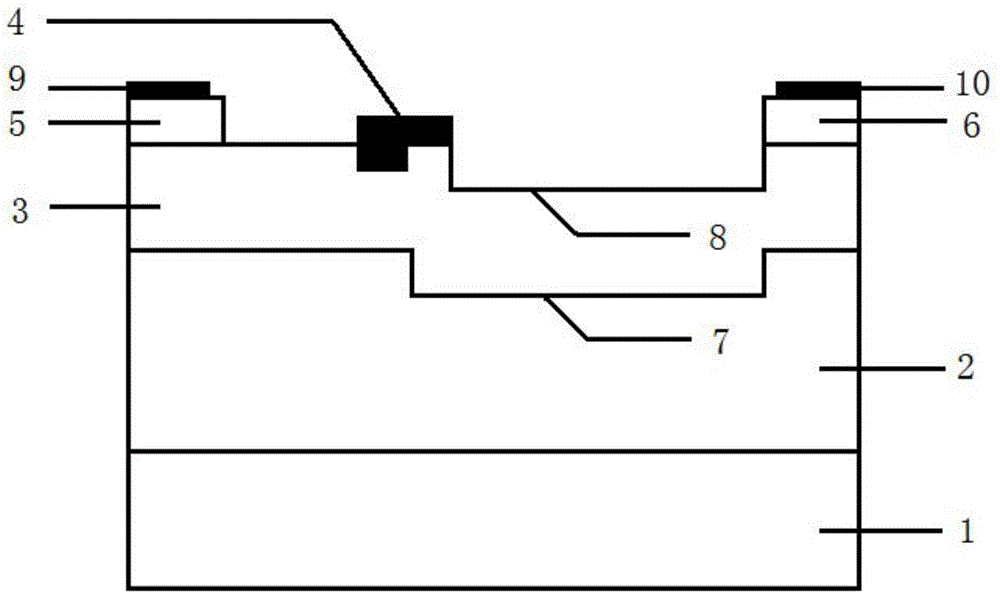

4H-SiC metal semiconductor field effect transistor having partial sinking channel

A field-effect transistor and metal-semiconductor technology, which is applied in the field of 4H-SiC metal-semiconductor field-effect transistors, can solve problems such as device breakdown voltage suppression and drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A 4H-SiC metal-semiconductor field-effect transistor with a recessed gate-drain buffer layer thickness and a recessed gate-drain drift region thickness of 0.1 μm is manufactured.

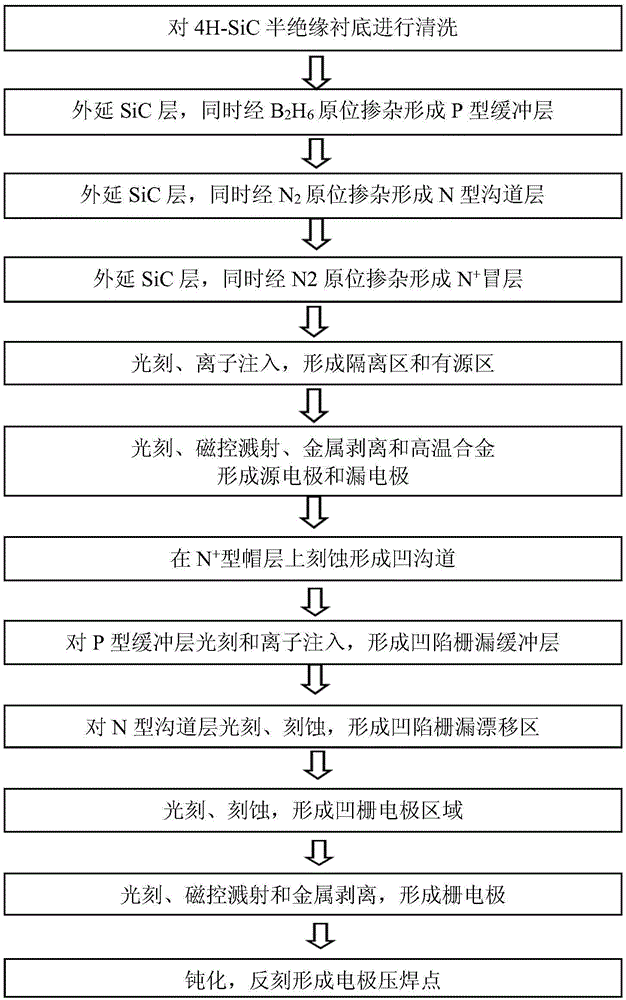

[0036] The manufacturing steps of this embodiment are as follows:

[0037] Step 1: cleaning the 4H-SiC semi-insulating substrate 1 to remove surface pollutants.

[0038] (1.1) Carefully wash the substrate twice with a cotton ball dipped in methanol to remove SiC particles of various sizes on the surface;

[0039] (1.2) Place the substrate in H 2 SO4 :HNO 3 = Ultrasound for 5 minutes in 1:1;

[0040] (1.3) Put the substrate in 1# cleaning solution (NaOH:H 2 o 2 :H 2 O=1:2:5), boiled for 5 minutes, rinsed with deionized water for 5 minutes, and then put into 2# cleaning solution (HCl:H 2 o 2 :H 2 O=1:2:7) and boiled for 5 minutes. Finally rinsed with deionized water and rinsed with N 2 Blow dry and set aside.

[0041] Step 2: epitaxially grow a SiC layer on the surface of the 4H-SiC...

Embodiment 2

[0085] A 4H-SiC metal-semiconductor field-effect transistor with a recessed gate-drain buffer layer thickness and a recessed gate-drain drift region thickness of 0.08 μm was fabricated.

[0086] Step 8: Photoetching and ion implanting the P-type buffer layer 2 to form a recessed gate-drain buffer layer 7 .

[0087] (8.1) Use positive photoresist, glue coating speed: 3000R / min, glue thickness > 2μm to ensure that it can play a good blocking role in the subsequent isolation injection;

[0088] (8.2) After gluing is completed, pre-bake in an oven at 90°C for 90 seconds, use a stepped buffer layer photolithography plate for about 35 seconds of UV exposure, and then develop in a special developer (tetramethylammonium hydroxide: water = 1:3) 60 seconds, then post-bake in an oven at 100°C for 3 minutes;

[0089] (8.3) Perform nitrogen ion implantation, the implantation condition is 240keV / 2×10 12 cm -2 , the temperature is 400°C. After the injection is completed, use acetone + ul...

Embodiment 3

[0097] A 4H-SiC metal-semiconductor field-effect transistor with a recessed gate-drain buffer layer thickness and a recessed gate-drain drift region thickness of 0.11 μm was fabricated.

[0098] Step 8: Photoetching and ion implanting the P-type buffer layer 2 to form a recessed gate-drain buffer layer 7 .

[0099] (8.1) Use positive photoresist, glue coating speed: 3000R / min, glue thickness > 2μm to ensure that it can play a good blocking role in the subsequent isolation injection;

[0100] (8.2) After gluing is completed, pre-bake in an oven at 90°C for 90 seconds, use a stepped buffer layer photolithography plate for about 35 seconds of UV exposure, and then develop in a special developer (tetramethylammonium hydroxide: water = 1:3) 60 seconds, then post-bake in an oven at 100°C for 3 minutes;

[0101] (8.3) Perform nitrogen ion implantation, the implantation condition is 270keV / 2×10 12 cm -2 , the temperature is 400°C. After the injection is completed, use acetone + ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com