Maca tablet candy containing tagatose and Maca tablets

A technology for compressing candy and maca tablets, which is applied in confectionery, confectionary industry, food science, etc., can solve the problems of not being able to adjust the intestinal microecological balance and not being suitable for consumption, so as to enhance key blood factors and promote The effect of healthy blood and appropriate fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

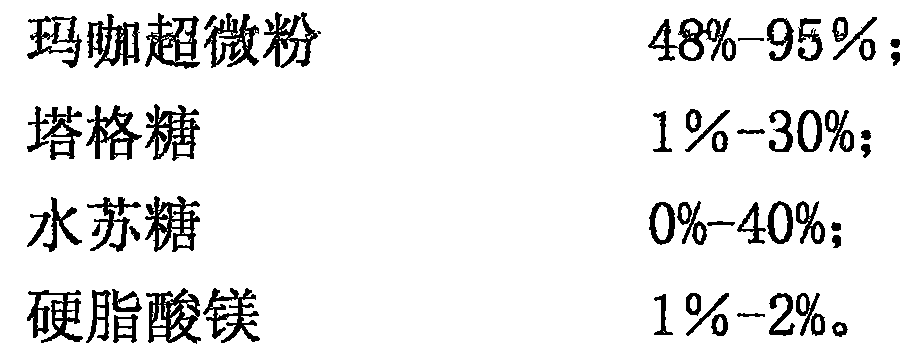

[0088] Maca pressed tablet candy formula one (percentage by weight):

[0089] 1. Maca superfine powder is preferably 49%;

[0090] 2. Tagatose is preferably 30%;

[0091] 3. Stachyose is preferably 20%;

[0092] 4. Magnesium stearate is preferably 1%.

[0093] The purity of tagatose is ≥98%.

[0094] Adding additives in the production process:

[0095] Wetting agent: appropriate amount of ethanol, purity 90%.

[0096] Production method: according to the formula, put maca superfine powder and tagatose into a V-shaped mixer and mix evenly, add ethanol to make soft material, put the soft material into a swinging granulator for granulation, and crush it with a 20-mesh sieve Whole granules; dry the wet granules in a blast drying oven below 60°C until the water content is less than 3%, add magnesium stearate to the dry granules, mix evenly, and press into tablets to make maca tablet candies: 0.5 per piece g / tablet, in aluminum-plastic blister pack or bottle.

Embodiment 2

[0098] Maca pressed tablet candy formula two (percentage by weight):

[0099] 1. Maca superfine powder is preferably 49%;

[0100] 2. Tagatose is preferably 15%;

[0101] 3. Stachyose is preferably 35%;

[0102] 4. Magnesium stearate is preferably 1%.

[0103] The purity of tagatose is ≥98%.

[0104] Adding additives in the production process:

[0105] Wetting agent: appropriate amount of ethanol, purity 90%.

[0106] Production method: with embodiment one.

Embodiment 3

[0108] Maca tablet formula one (percentage by weight):

[0109] 1. Maca superfine powder is preferably 95%;

[0110] 2. Tagatose is preferably 1%;

[0111] 3. Stachyose is preferably 0%;

[0112] 4. Magnesium stearate is preferably 1%.

[0113] The purity of tagatose is ≥98%.

[0114] Adding additives in the production process:

[0115] Wetting agent: appropriate amount of ethanol, purity 90%.

[0116] Production method: with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com