Flower-shaped tungsten oxide nanometer material and preparing method thereof

A technology of nanomaterials and tungsten oxide, applied in the direction of tungsten oxide/tungsten hydroxide, nanotechnology, etc., can solve the problems of difficult preparation of nano tungsten oxide materials and low controllability, and achieve cheap and easy raw materials and short preparation time , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

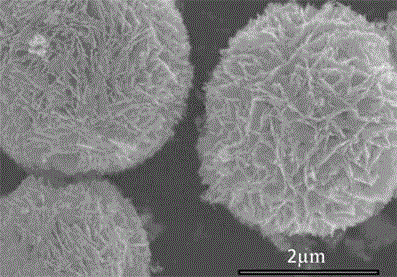

[0024] 0.3g of ammonium tungstate (molecular weight: 3042), 20g of absolute ethanol, 4.2g of a binary organic acid, 0.1g of taurine were ultrasonically oscillated for 10 minutes, and the uniformly dispersed solution was poured into the core of the polytetrafluoroethylene reactor And put it in an oven at 200°C for 4 hours of constant temperature reaction, cool it down to room temperature naturally, wash and dry the product by centrifugation, and then obtain spherical flower-shaped nano-tungsten oxide powder. figure 1 It is the scanning electron microscope (SEM) image of the nano-tungsten oxide prepared in Example 1. Figure 4 It is the XRD pattern of nano tungsten oxide prepared in Example 1.

Embodiment 2

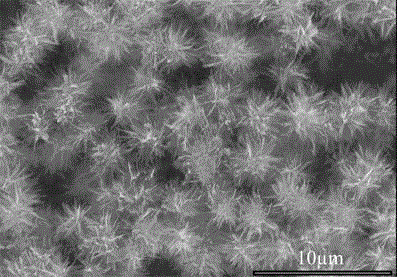

[0026] Ultrasound oscillate 0.5g ammonium tungstate (molecular weight 3042), 23g absolute ethanol, 4.5g a certain binary organic acid, 0.15g taurine for 10 minutes, and pour the uniformly dispersed solution into the core of the polytetrafluoroethylene reactor And put it in an oven at 230°C for 2 hours of constant temperature reaction, cool down to room temperature naturally, wash and dry the obtained product by centrifugation, and then obtain spherical flower-shaped nano-tungsten oxide powder. figure 2 It is the scanning electron microscope (SEM) image of the nano-tungsten oxide prepared in Example 2.

Embodiment 3

[0028] Ultrasound oscillate 0.2g ammonium tungstate (molecular weight: 3042), 15g absolute ethanol, 3.1g certain binary organic acid, 0.07g taurine for 10 minutes, pour the uniformly dispersed solution into the core of polytetrafluoroethylene reactor And placed in an oven at 150°C for constant temperature reaction for 8 hours, cooled naturally to room temperature, and the obtained product was centrifugally washed and dried to obtain a spherical flower-shaped nano-tungsten oxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com