Ozone oxidation treatment leachate nanofiltration concentrate treatment method

A technology of ozone oxidation and treatment method, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., which can solve the problems of high treatment cost, salt accumulation, and treatment system collapse, and reduce the Effects of treatment cost, increase in ozone concentration, and increase in utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

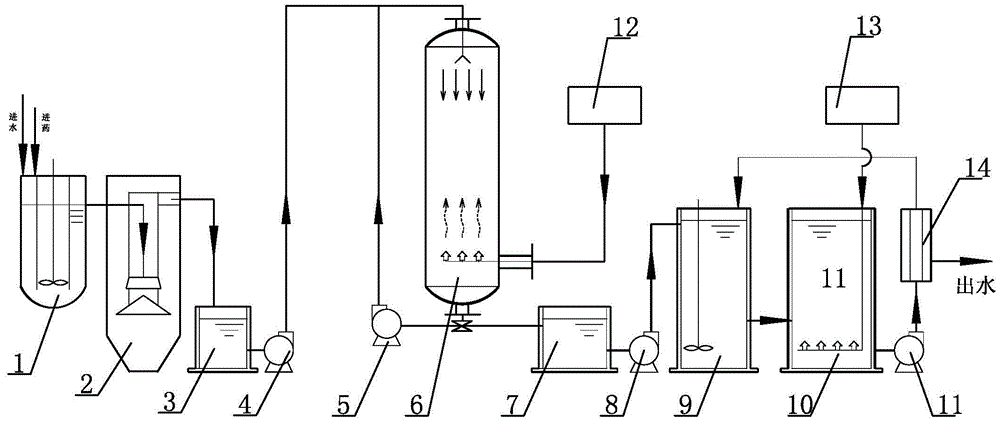

[0013] The method for treating leachate nanofiltration concentrated liquid by ozone oxidation treatment of the present invention comprises coagulation sedimentation treatment, ozone oxidation treatment and membrane biological reaction treatment.

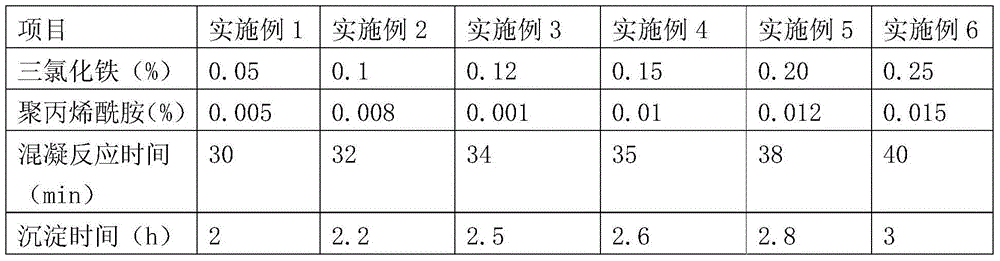

[0014] See figure 1 As shown, the present invention first enters the coagulation and precipitation treatment, and the leachate nanofiltration concentrate, ferric chloride and polyacrylamide are added in the stirred tank 1, and the ferric chloride and the polypropylene in the stirred tank 1 are mixed by the stirrer. Amide and leachate nanofiltration concentrated solution are fully mixed, carry out coagulation reaction, after coagulation reaction takes place in the reaction zone of stirring tank 1, add to sedimentation tank 2, by mass percentage, the add-on of ferric chloride of the present invention is 0.05~0.25% of the total amount of leachate nanofiltration concentrate, the addition of polyacrylamide is 0.005~0.015% of the total amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com