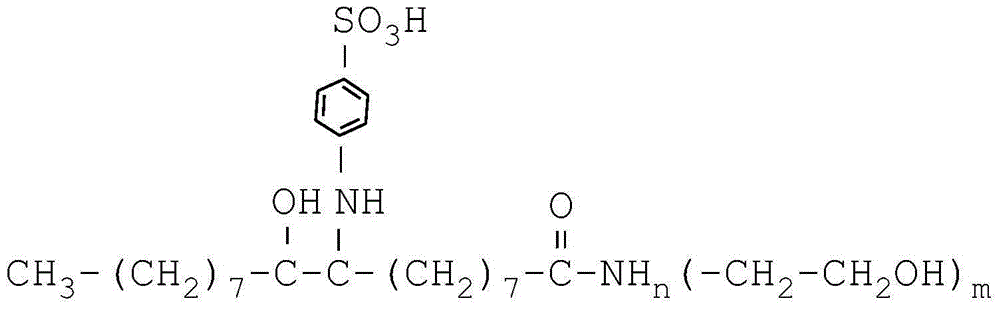

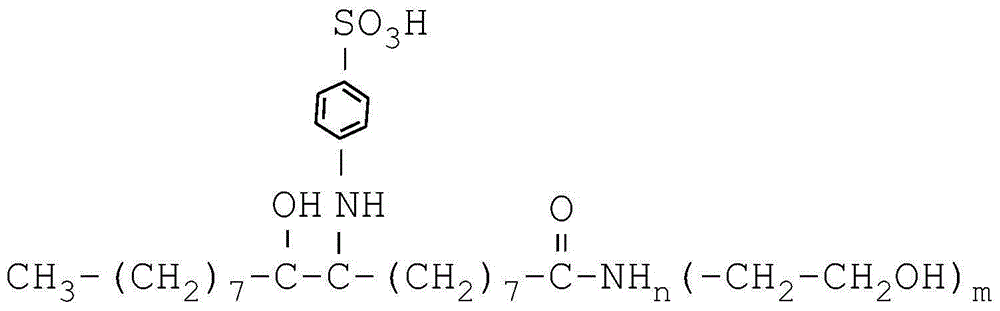

Papermaking felt cleaning agent, oleamide benzene sulfonic acid, and preparation method thereof

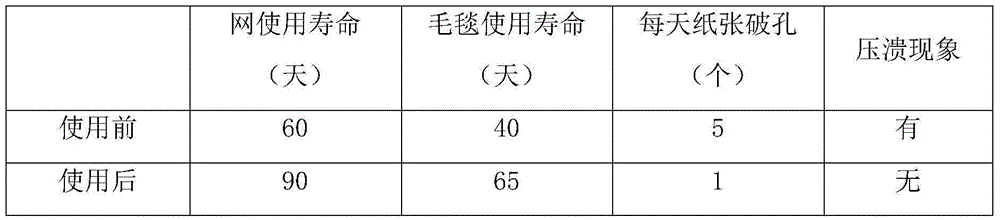

A technology similar to benzenesulfonic acid and oleic acid amide, which is applied in the field of papermaking, can solve the problems of biodegradability, poor environmental protection, low cleaning efficiency, and excessive waste water generation, and achieve scientific and reasonable preparation methods, improve production efficiency, and expand production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of oleic acid amides benzenesulfonic acid of the present invention, it comprises the following steps:

[0026] 1) Using oleic acid ethanolamide as raw material, NKC-9 strongly acidic cation exchange resin as catalyst, organic acid as oxygen carrier, hydrogen peroxide as oxidant, in parts by mass, 100 parts of oleic acid ethanolamide, 5-15 parts of Catalyst dosage, 80-120 parts of 30%-50% hydrogen peroxide, 10-20 parts of organic acid, epoxidized oleic acid ethanolamide reaction, reaction time 5-7h, reaction temperature 50-70°C, after the reaction, The catalyst is filtered out, and the acid water mixed with organic acid and hydrogen peroxide is separated to obtain epoxy oleic acid ethanolamide;

[0027] 2) Add p-aminobenzenesulfonic acid in the epoxy oleic acid ethanolamide that step 1) obtains, by mass parts, the epoxy oleic acid ethanolamide of 100 parts, the p-aminobenzenesulfonic acid of 20-25 parts, at temperature 60-80°C, reaction time 7-9h,...

Embodiment 1

[0031] The preparation method of the oleic acid amides benzenesulfonic acid of embodiment 1 may further comprise the steps:

[0032] 1) In parts by mass, 100 parts of oleic acid ethanolamide, 5 parts of catalyst consumption, 80 parts of 30% hydrogen peroxide, and 10 parts of organic acid are used for epoxidized oleic acid ethanolamide reaction, the reaction time is 5h, and the reaction temperature is 50°C, after the reaction is over, filter out the catalyst, and separate the acid water mixed with organic acid and hydrogen peroxide to obtain epoxy oleic acid ethanolamide;

[0033] 2) Add p-aminobenzenesulfonic acid to the epoxy oleic acid ethanolamide obtained in step 1), in parts by mass, 100 parts of epoxy oleic acid ethanolamide, 20 parts of p-aminobenzenesulfonic acid, at a temperature of 60 ° C , The reaction time is 7h, after the amino group on the p-aminobenzenesulfonic acid and the epoxy group on the epoxy oleic acid amide undergo a ring-opening reaction to generate ole...

Embodiment 2

[0035] The preparation method of the oleic acid amides benzenesulfonic acid of embodiment 2 may further comprise the steps:

[0036] 1) In parts by mass, 100 parts of oleic acid ethanolamide, 10 parts of catalyst consumption, 100 parts of 40% hydrogen peroxide, and 15 parts of organic acid are used for epoxidized oleic acid ethanolamide reaction, the reaction time is 6h, and the reaction temperature is 60°C, after the reaction is over, filter out the catalyst, and separate the acid water mixed with organic acid and hydrogen peroxide to obtain epoxy oleic acid ethanolamide;

[0037] 2) Add p-aminobenzenesulfonic acid to the epoxy oleic acid ethanolamide obtained in step 1), in parts by mass, 100 parts of epoxy oleic acid ethanolamide, 23 parts of p-aminobenzenesulfonic acid, at a temperature of 70°C , The reaction time is 8h, after the amino group on the p-aminobenzenesulfonic acid and the epoxy group on the epoxy oleic acid amide ring-opening reaction to generate oleic acid am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com