Homogeneous core-shell composite material PPy @ PANI and preparation method thereof

A composite material, core-shell technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low polyaniline usage, increased polyaniline usage, uneven particles, etc., and achieves strong absorption capacity and wide absorption bandwidth. , the effect of enhancing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

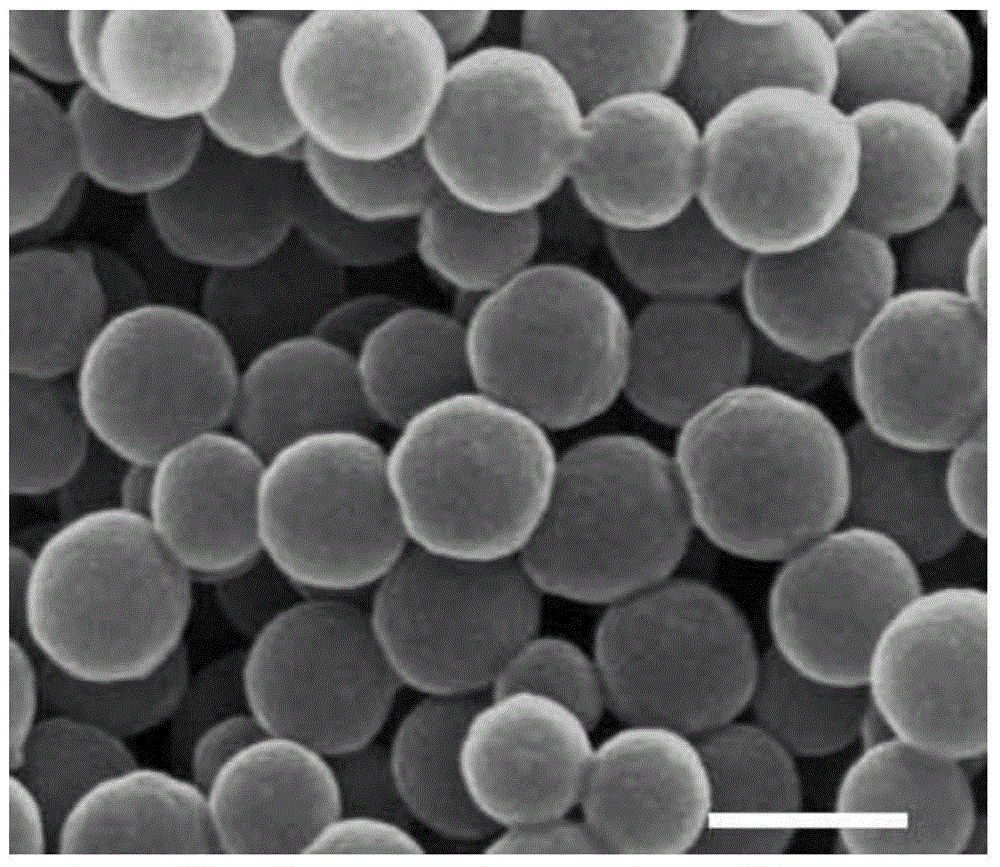

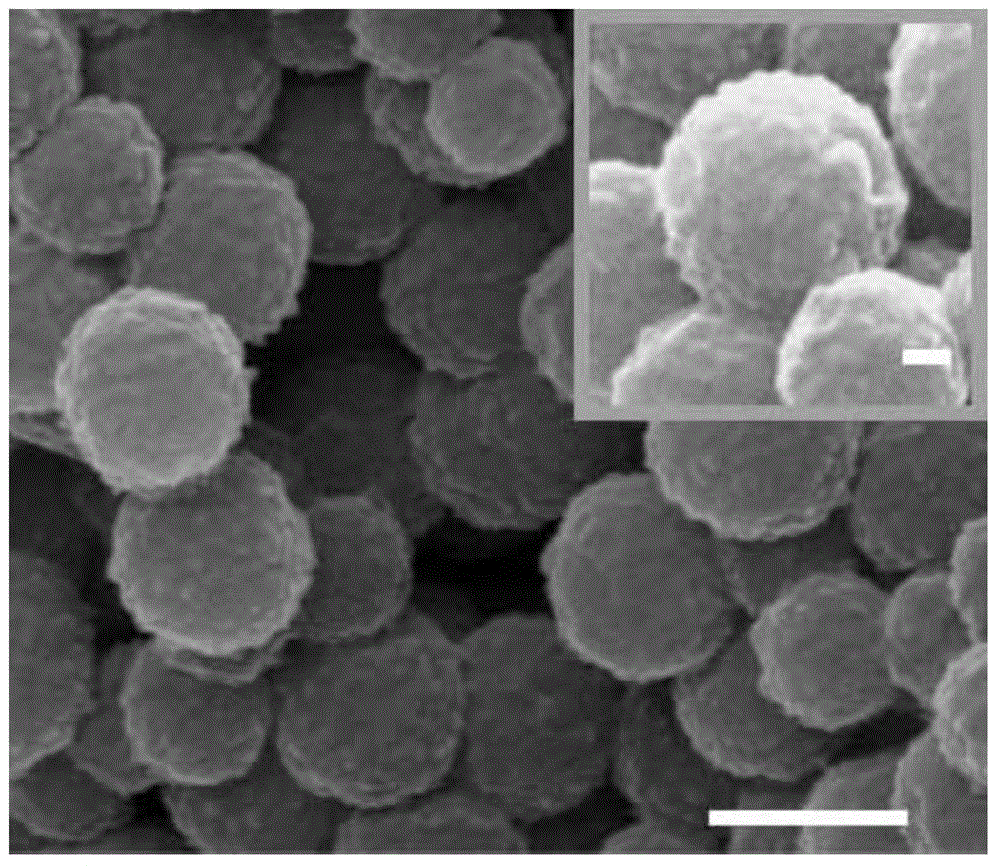

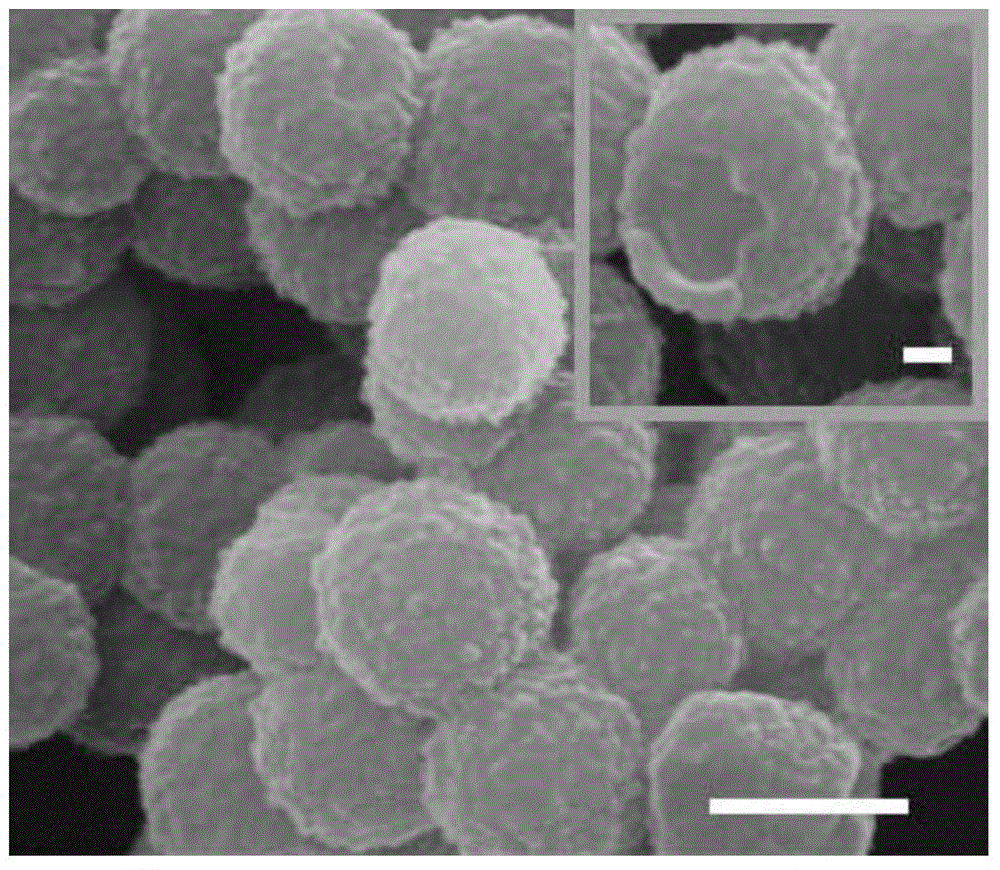

[0036] Embodiment 1: In this embodiment, the homogeneous core-shell composite material PPyPANI uses polypyrrole as the core material and polyaniline as the wall material.

specific Embodiment approach 2

[0037] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio of polypyrrole as the core material to polyaniline as the wall material is 1:(0.2-2). Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0038] Specific embodiment three: The uniform core-shell composite material PPyPANI of this embodiment is prepared according to the following steps:

[0039] 1. Preparation of PPy balls: 0.08~0.12g FeCl 2 4H 2 O was dispersed in 60mL deionized water, then 0.8-1.2mL pyrrole monomer was added, and then 5-8mL H 2 o 2 React for 12 hours, then wash with acetone, and dry at 60°C for 12 hours;

[0040] 2. Disperse the polypyrrole microspheres prepared in step 1 into the hydrochloric acid solution, stir for 1 h under ice-water bath conditions, then add aniline monomer and ammonium persulfate under ice-water bath conditions and react for 24 hours, then wash with distilled water and ethanol, Then place it in an environment of 60° C. and dry for 12 hours; the homogeneous core-shell composite material PPyPANI is obtained.

[0041] The concentration of the hydrochloric acid solution in Step 2 of this embodiment is 0.1 mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com