Catalytic decomposition type air purification material and preparation method thereof

An air purification material and catalytic decomposition technology, applied in the field of air purification, can solve the problems of poor practicability and high cost, and achieve the effects of thorough air purification, simple preparation process, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

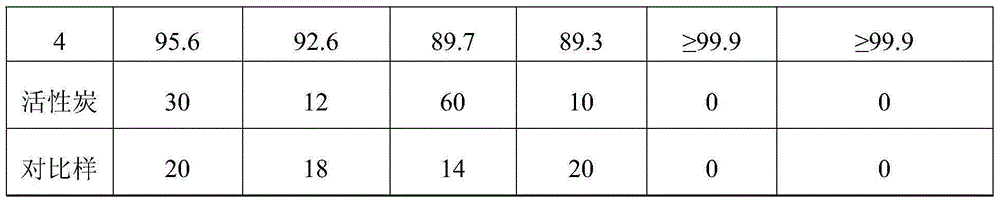

Examples

preparation example Construction

[0013] A method for preparing a catalytic decomposition type air purification material, characterized in that it comprises the following steps:

[0014] 1) Combine clay, air-permeable glue, CuO nanorods, coconut shell activated carbon powder and nano photosensitive metal oxides, active MnO 2 The nanorods are uniformly mixed with water to prepare a mixed slurry. In the mixed slurry, binder, air-permeable glue, CuO nanorods, coconut shell activated carbon powder, nano photosensitive metal oxide, active MnO 2 The weight ratio of nanorods and water is (0.6~1):(2~8):(0~1):(0~1):(0~0.9):10:(20~30);

[0015] 2) Attach the mixed slurry prepared in step 1) to the substrate by soaking, spraying or coating, and dry at 80°C to 110°C to obtain a catalytic decomposition type air purification material.

[0016] A catalytic decomposition type air purification material is characterized in that its preparation raw materials include binder, breathable glue, CuO nanorods, coconut shell activate...

Embodiment 1

[0029] This embodiment provides a catalytic decomposition type air purification material and its preparation method, specifically:

[0030] 1) Mix potassium permanganate, manganese sulfate, sodium hydroxide and distilled water with a weight ratio of 1:1:0.1:6 respectively, and transfer the mixture into a high-pressure reactor with a polytetrafluoroethylene lining , then add distilled water to adjust to 60% of the volume of the inner lining of the reaction kettle, seal it, heat up to 140°C, react for 4h, suction filter after the reaction, and place it in a vacuum drying oven, heat from room temperature to 180°C, and react at constant temperature for 6h. Cool naturally to room temperature to produce α / β active MnO 2 Nano stave.

[0031] 2) Slowly add 1L of 1mol / L urea solution dropwise to an equal volume of 1mol / L divalent copper salt solution, transfer the mixed solution into a high-pressure reactor with a polytetrafluoroethylene liner, and then add Distilled water is adjuste...

Embodiment 2

[0034] This embodiment provides a catalytic decomposition type air purification material and its preparation method, specifically:

[0035] 1) Mix potassium permanganate, manganese acetate, potassium hydroxide and distilled water in a weight ratio of 1:1.1:0.2:6.1, respectively, and transfer the mixed solution into a high-pressure reactor with a polytetrafluoroethylene liner, Then add distilled water to adjust to 65% of the volume of the inner lining of the reactor, seal it, raise the temperature to 150°C, and react for 4 hours. Cool down to room temperature to produce β / γ-type active MnO 2 Nano stave.

[0036] 2) Slowly add 1L of 1mol / L urea solution dropwise to an equal volume of 1mol / L divalent copper salt solution, transfer the mixed solution into a high-pressure reactor with a polytetrafluoroethylene liner, and then add Distilled water is adjusted to 65% of the volume of the inner lining of the reactor, sealed, heated to 110°C, reacted for 4 hours, filtered after the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com