Hydro-thermal synthesis method for molybdenum-sulphur co-doped mesoporous nano titanium dioxide visible-light-driven photocatalyst

A mesoporous titanium dioxide, hydrothermal synthesis technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of loose combination, waste of synthesis time and reaction consumption, etc., to achieve reaction Simple process, high efficiency, tightly combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] a. First prepare titanium glycolate according to the prior known technology: take 25mL ethylene glycol, and then pass nitrogen into it for 10 minutes to remove oxygen and moisture. Quickly transfer it into a glove box filled with dry nitrogen or argon. In the glove box, add 1.5 µL of titanium tetrachloride and 1 mL of titanium isopropoxide to the solution and keep stirring for 12 h. Subsequently, the solution was taken out from the glove box, and quickly poured into a mixed solution of 1 mL of water and 100 mL of acetone in a state of rapid stirring, and sealed and stirred for 6 hours. The resulting white product solution was centrifuged several times, and washed several times with water and ethanol to remove excess ethylene glycol on the product surface.

[0023] b. Take 120 mg of the titanium glycolate precursor synthesized above, 97 mg of sodium molybdate dihydrate, 190 mg of thiourea and 60 mL of water to make a solution.

[0024] c. put the solution obtained in t...

Embodiment 2

[0027] The preparation process and steps of this embodiment are basically the same as in Example 1, except that step c: the solution obtained in the previous step is put into a high-pressure reactor with a polytetrafluoroethylene lining and reacted for 12 hours at 200 ° C; After the obtained product is conventionally centrifuged, washed and dried, a molybdenum-sulfur-doped mesoporous titanium dioxide nanometer visible light catalyst is obtained.

Embodiment 3

[0029] The preparation process and steps of this embodiment are basically the same as in Example 1, except that step c: the solution obtained in the previous step is put into a high-pressure reactor with a polytetrafluoroethylene lining and reacted for 1 hour at 200 ° C; After the obtained product is conventionally centrifuged, washed and dried, a molybdenum-sulfur-doped mesoporous titanium dioxide nanometer visible light catalyst is obtained.

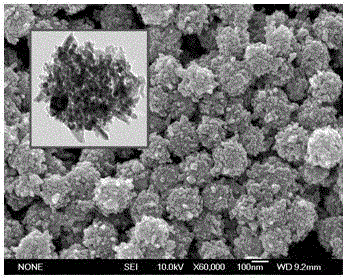

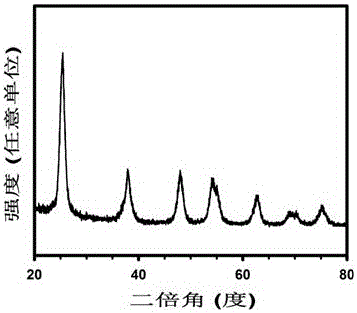

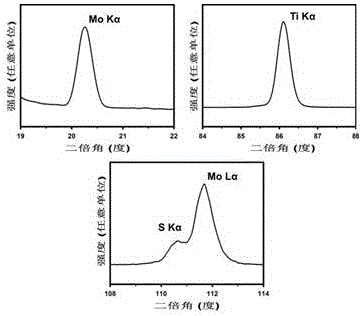

[0030] The resulting samples were characterized, and some of the results are shown in the accompanying drawings. It can be found that with the prolongation of the hydrothermal reaction time, the small particles on the surface of the synthesized nanomaterials gradually grow up, and the size of the mesopores also gradually increases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com