Strong-reducing-property visible light response photocatalyst with urea and ferric chloride as raw materials

A photocatalyst and ferric chloride technology, applied in the field of environment and materials, can solve the problems of reducing the degradation efficiency of pollutants in water, easy oxidation and aggregation, and achieve good economic and environmental benefits, improve catalytic efficiency, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

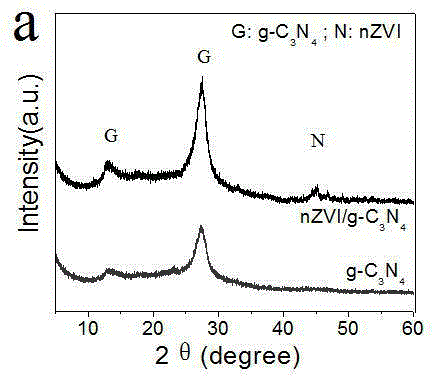

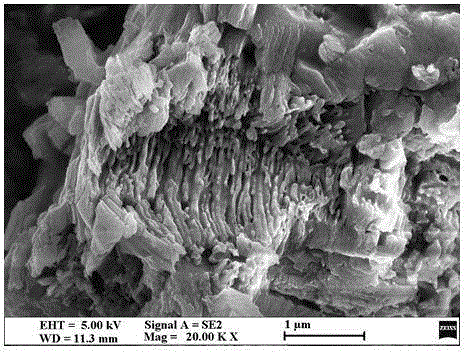

[0028] Put urea into a mortar, grind and pulverize it, and calcinate it at 550°C for 4 hours, and the obtained block g-C 3 N 4 , added to methanol solution, after ultrasonic treatment for 1h, heated in water bath for 3h, washed with methanol, filtered, and dried to obtain flaky g-C 3 N 4 , by sheet g-C 3 N 4 : The mass ratio of nano-iron=100:0.5 weighs ferric chloride (FeCl 3 ) and flake g-C 3 N 4 , stirred for 2 hours to obtain a suspension, sodium borohydride ethanol solution (10 mg / ml) was added to the obtained suspension, stirred for 1 hour, centrifuged, washed and dried to obtain a strong reducing visible light response photocatalyst.

[0029] Weigh 50mg of the strong reductive visible light response photocatalyst that is made, add to the mixed solution of 50ml (rhodamine B and CuCl 2 The concentration is 20ppm), using a xenon lamp as a light source, using a visible light filter to let the visible light of 400-780nm pass through the filter, and irradiate the sample...

Embodiment 2

[0031] Put urea into a mortar, grind and pulverize it, and calcinate it at 550°C for 4 hours, and the obtained block g-C 3 N 4 , added to methanol solution, after ultrasonic treatment for 1h, heated in water bath for 3h, washed with methanol, filtered, and dried to obtain flaky g-C 3 N 4 , press g-C 3 N 4: Nano iron = 100:1 ratio to weigh ferric chloride (FeCl 3 ) and flake g-C 3 N 4 , stirred for 2 hours to obtain a suspension, sodium borohydride ethanol solution (10 mg / ml) was added to the obtained suspension, stirred for 1 hour, centrifuged, washed and dried to obtain a strong reducing visible light response photocatalyst.

[0032] Weigh 50mg of the strong reductive visible light response photocatalyst that is made, add to the mixed solution of 50ml (rhodamine B and CuCl 2 The concentration is 20ppm), using a xenon lamp as a light source, using a visible light filter to let the visible light of 400-780nm pass through the filter, and irradiate the sample. After a cert...

Embodiment 3

[0034] Put urea into a mortar, grind and pulverize it, and calcinate it at 550°C for 4 hours, and the obtained block g-C 3 N 4 , added to methanol solution, after ultrasonic treatment for 1h, heated in water bath for 3h, washed with methanol, filtered, and dried to obtain flaky g-C 3 N 4 , press g-C 3 N 4 : The ratio of nano-iron=100:1.5 weighs ferric chloride (FeCl 3 ) and flake g-C 3 N 4 , stirred for 2 hours to obtain a suspension, sodium borohydride ethanol solution (10 mg / ml) was added to the obtained suspension, stirred for 1 hour, centrifuged, washed and dried to obtain a strong reducing visible light response photocatalyst.

[0035] Weigh 50mg of the strong reductive visible light response photocatalyst that is made, add to the mixed solution of 50ml (rhodamine B and CuCl 2 The concentration is 20ppm), using a xenon lamp as the light source, using a visible light filter to let the visible light of 400-780nm pass through the filter, and irradiate the sample. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com