Denitration catalyst with titanium-aluminum-cerium composite oxide as carrier and preparation method thereof

A technology for composite oxides and denitration catalysts is applied in the field of preparation of flue gas denitration catalysts, which can solve the problems of no reports of wide temperature catalysts, flue gas temperature fluctuations, few clear reports, etc. Good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

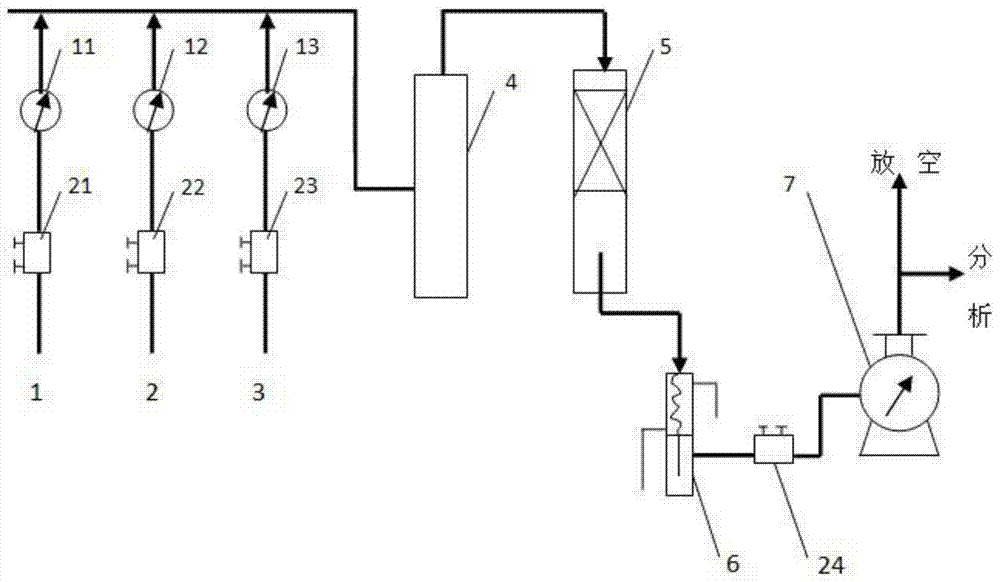

Method used

Image

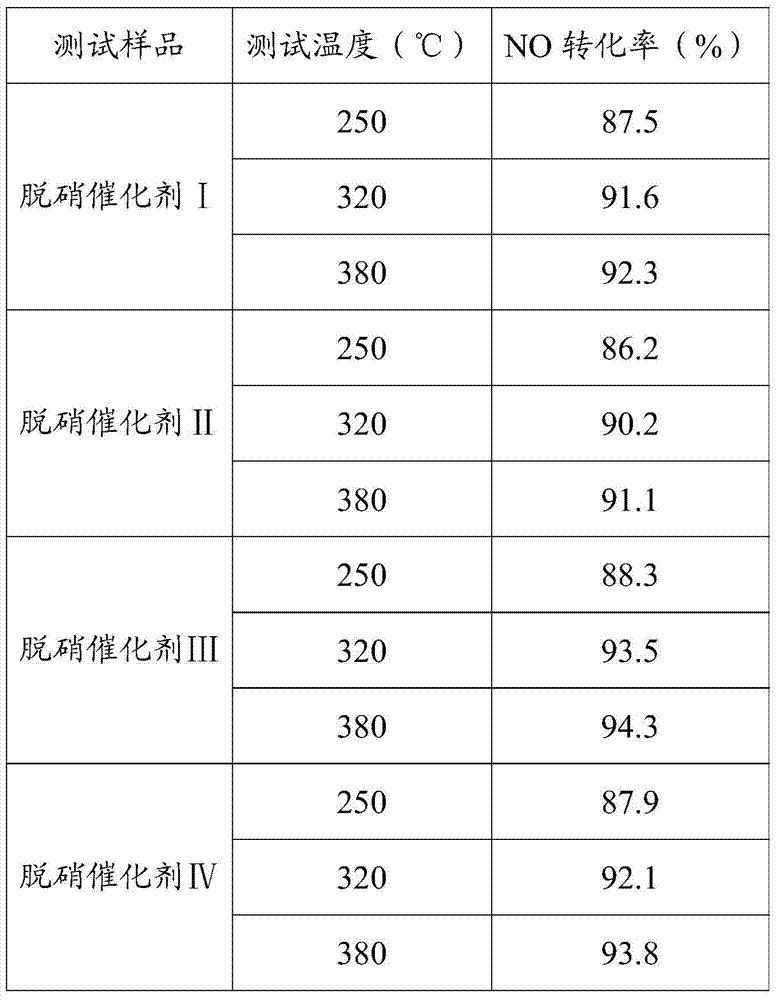

Examples

example 1

[0053] Example 1: Preparation of an out-of-sale catalyst based on a titanium-aluminum-cerium composite oxide

[0054] (1) Mix 400g titanium dioxide, 50g pseudoboehmite, 50g cerium hydroxide and 105g nitric acid (concentration: 0.1mol / L) evenly, then age at room temperature for 18h, then dry at 70°C for 24h, then Calcined at 500°C for 6h to obtain titanium-aluminum-cerium composite oxide.

[0055] (2) dissolving ammonium metatungstate and ammonium metavanadate in an oxalic acid solution with a mass concentration of 5% to obtain an impregnation solution. Take 0.5L of immersion solution, in which the concentration of ammonium metatungstate is 48.6g / L, and the concentration of ammonium metavanadate is 20.8g / L. Grind the titanium-aluminum-cerium composite oxide prepared in step 1, pass it through a 200-mesh sieve and put it in the impregnation solution, stir at 45°C for 3.0h, then raise the temperature to 85°C until no liquid material flows (that is, evaporate to dryness ). Dry ...

example 2

[0058] Example 2: Preparation of an out-of-sale catalyst supported by a titanium-aluminum-cerium composite oxide

[0059] (1) Mix 400g titanium dioxide, 61.5g pseudoboehmite, 51.3g cerium hydroxide and 112.6g nitric acid (concentration: 0.1mol / L), then age at room temperature for 22h, and then dry at 75°C 24h, and then calcined at 550°C for 4h to obtain a titanium-aluminum-cerium composite oxide.

[0060] (2) Dissolving ammonium metatungstate and ammonium metavanadate in an oxalic acid solution with a mass concentration of 5.5% to obtain an impregnation solution. Take 0.5L of immersion solution, in which the concentration of ammonium metatungstate is 47.6g / L, and the concentration of ammonium metavanadate is 20.3g / L. Grind the titanium-aluminum-cerium composite oxide prepared in step 1, pass it through a 200-mesh sieve and put it in the impregnation solution, stir at 50°C for 3.0h, then raise the temperature to 90°C until no liquid material flows (that is, evaporate to drynes...

example 3

[0063] Example 3: Preparation of an out-of-sale catalyst supported by a titanium-aluminum-cerium composite oxide

[0064] (1) Mix 400g of titanium dioxide, 61g of pseudo-boehmite, 47g of cerium hydroxide and 99.8g of nitric acid (0.15mol / L concentration), then age at room temperature for 18h, then dry at 70°C for 24h, Then calcined at 500° C. for 6 hours to obtain titanium-aluminum-cerium composite oxide.

[0065] (2) Dissolving ammonium metatungstate and ammonium metavanadate in an oxalic acid solution with a mass concentration of 6% to obtain an impregnation solution. Take 0.5L of immersion solution, in which the concentration of ammonium metatungstate is 44.3g / L, and the concentration of ammonium metavanadate is 21.8g / L. Grind the titanium-aluminum-cerium composite oxide prepared in step 1, pass it through a 200-mesh sieve and put it in the impregnation solution, stir at 40°C for 4.0h, then raise the temperature to 80°C until no liquid material flows (that is, evaporate to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com