Au@SiO2 mesoporous composite nanomaterial and preparation method thereof

A composite nanomaterial and mesoporous technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of easy aggregation of nanoparticles, and achieve the effect of uniform distribution and narrow size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

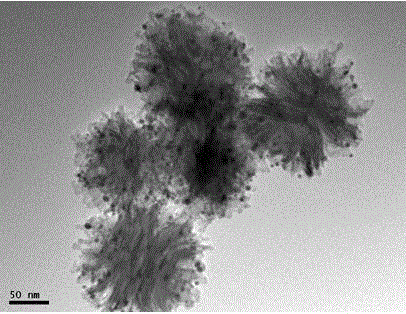

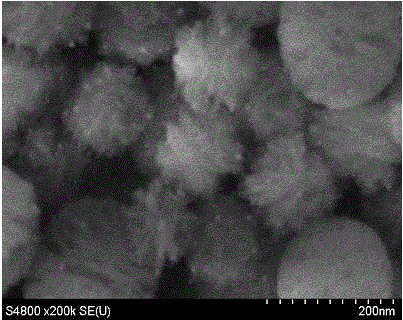

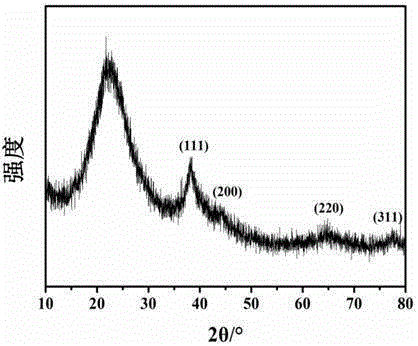

Embodiment 1

[0023] a. Use an electronic balance to weigh 1.38g of cetyltrimethylammonium bromide (CTAB), add it into 70mL of deionized water and ultrasonically dissolve it; measure 15mL of ethyl acetate (EA) and 5mL of ethanol into the above solution , after stirring evenly, add 0.8mL ammonia water (25~28wt%), then add 2.5mL tetraethyl orthosilicate (TEOS), and continue stirring for 30min;

[0024] b. Pour the above mixed solution into a 150mL autoclave lined with polytetrafluoroethylene, and react at 100°C for 24 hours; after the reaction is completed, centrifuge the reactant and wash it repeatedly with ethanol and deionized water Finally, dry at 60°C;

[0025] c. Dissolve the product after centrifugation and drying in 1μg / mL acetone, react at 60°C for 6h, repeat two to three times, and then dissolve 100mg of the product obtained after conventional centrifugation, washing, drying and other steps into 100mL Add 100 μL of 3-aminopropyltriethoxysilane (APTES) to isopropanol, sonicate for 0...

Embodiment 2

[0029] The preparation process and steps of this embodiment are basically the same as in Example 1, except that the d step:

[0030] No 3-aminopropyltriethoxysilane (APTES) was added.

[0031] The results obtained are not significantly different from those of Example 1 in morphology and pore structure, but only a small amount of Au nanoparticles are loaded on the surface and the agglomeration is serious, and the particle size of individual Au nanoparticles reaches more than 20nm.

Embodiment 3

[0033] The preparation process and steps of this embodiment are basically the same as in Example 1, except that the b step:

[0034] Measure 15mL of ethyl acetate (EA) and 10mL of ethanol into the above solution.

[0035]The results obtained are quite different from those in Example 1, Au@SiO 2 The particle size becomes larger obviously, about 250nm, and the whole is emissive channel structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com