A method for preparing polymeric aluminum-iron flocculant from steel wire rope acid mud

A technology of polymerizing aluminum-iron and steel wire ropes, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, sludge treatment, etc., can solve problems such as waste of resources, underutilization of metal elements, occupation of landfill sites, etc., to achieve The effect of excellent purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

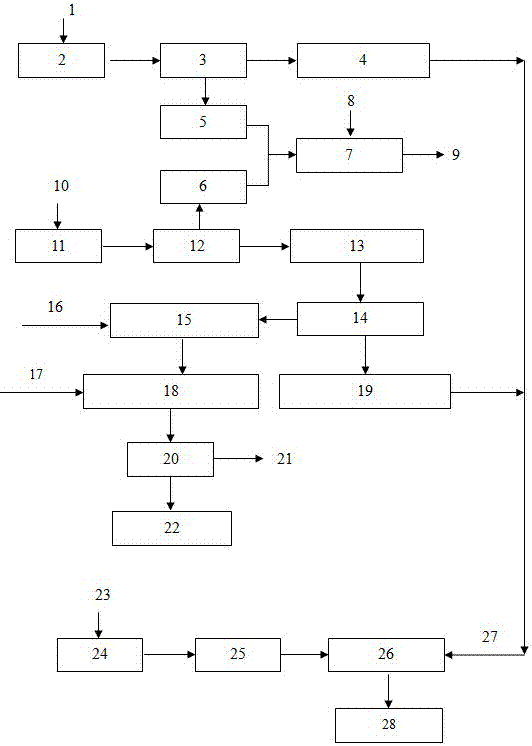

[0024] See figure 1 , Add 2000L of sulfuric acid solution 1 with a mass concentration of 10% into the reaction tank 2, then add 1000kg of sodium sludge with a water content of 75%, stir and react at room temperature for 30 minutes, and remove 10kg of sodium sludge residue A through the plate and frame filter press 3. 5. Obtain 2500L of sulfuric acid extract of sodium mud A4. Add 2000L of hydrochloric acid solution 10 with a mass concentration of 18% into the lime mud reactor 11, then add 1000kg of lime mud with a water content of 75%, stir at room temperature for 30 minutes, and remove 15kg of lime mud residue through a plate and frame filter press 12 B 6, to obtain 2500L of hydrochloric acid extract 13 of calcium mud. After the hydrochloric acid extract 13 of calcium mud was treated with D113 type macroporous weakly acidic acrylic cation exchange resin 14 for 60 minutes, a lead-removed calcium mud hydrochloric acid extract B19 was obtained.

[0025] (1) Preparation of polyalum...

Embodiment 2

[0029] See figure 1 , Add 2000L of sulfuric acid solution 1 with a mass concentration of 20% into the reaction tank 2, then add 1000kg of sodium sludge with 80% moisture content, stir and react at room temperature for 45 minutes, and remove 12kg of sodium sludge residue A 5 through the plate and frame filter press 3. , To obtain 2600L sodium mud sulfuric acid extract A4. Add 2000L of hydrochloric acid solution 10 with a mass concentration of 25% into the lime mud reactor 11, then add 1000kg of lime mud with a moisture content of 78%, stir at room temperature for 45 minutes, and remove 16kg of lime mud residue B through the plate and frame filter press 12. 6. Obtain 2600L of hydrochloric acid extract 13 of calcium mud. After the hydrochloric acid extract 13 of the lime mud was treated with a 201×7 type strong alkaline styrene-based anion exchange resin 14 for 60 minutes, a lead-removed lime mud hydrochloric acid extract B 19 was obtained.

[0030] (1) Preparation of polyaluminum...

Embodiment 3

[0033] Example 3: Use case

[0034] The polyaluminum iron flocculant prepared in Example 1 was used for domestic sewage treatment. At 1 m 3 Add 1.5 kg of polyaluminum iron flocculant to the domestic sewage, stir for 5 minutes, let it settle for 60 minutes, and take samples to test the effect of domestic sewage treatment. Before treatment, the turbidity of domestic sewage is 226.7 NTU, COD Cr 715.6 mg / L, ammonia nitrogen 32 mg / L, total phosphorus 3.8 mg / L, after treatment with polyaluminum iron flocculant, sewage turbidity dropped by 98%, COD Cr The removal rates of, ammonia nitrogen and total phosphorus are 78.5%, 80.3% and 80% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com