A strain of Aspergillus niger and its fermentation agent and its application

A technology for fermentation inoculum and Aspergillus niger, which is applied in the field of Aspergillus niger strains and fermentation inoculum, can solve the problems of slow decomposition rate of peanut shells, limited popularization and application, and difficult plant absorption and utilization of nutrients, so as to improve the quality of substrate products and reduce Waste of resources, the effect of accelerating the fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment one, the screening identification of Aspergillus niger strain

[0022] 1. Isolation and purification of bacterial strains

[0023] The rotten peanut shells from the Jiaozhou Bay Experimental Base in Qingdao City, Shandong Province were taken as samples. Shake flask enrichment culture was used, and the rotten peanut shells were placed in 100mL enrichment medium, 28°C, 180rpm constant temperature culture. Every 5 days, 10% of the inoculum was added to another enriched medium, and the acclimatization was repeated 5 times to obtain the enriched medium. The enrichment medium uses peanut shell powder as the sole carbon source.

[0024] Take 150 μL of the enriched culture solution and spread it on carboxymethylcellulose sodium (CMC-Na)-Congo red medium, culture at 28°C for 5 days. Pick the bacteria with a larger diameter of the hydrolysis circle and transfer them to the inorganic salt medium with sodium carboxymethyl cellulose as the only carbon source, and conti...

Embodiment 2

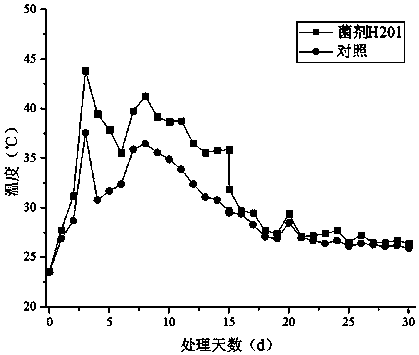

[0031] Example 2, Determination of Aspergillus niger H201 KP280086 strain on peanut shell decomposition

[0032] 2.1 Preparation of Aspergillus niger H201KP280086 suspension

[0033] Inoculate the activated H201KP280086 strain into sterilized CMC-Na liquid medium, the components of which are: CMC-Na 2.0 g, yeast extract 1.0 g, (NH 4 ) 2 SO 4 0.4 g, KH 2 PO 4 0.25 g, peptone 0.1 g, MgSO 4 ·7H 2 O0.01g, distilled water to 1000mL, pH 7.0, 28°C, 180rpm, shaking culture for 24h, made Aspergillus niger H201KP280086 bacterial suspension.

[0034] 2.2 Preparation of crude enzyme solution

[0035] The prepared bacterial suspension was inoculated into the peanut shell medium according to the inoculum amount of 5%. The components of the peanut shell medium are: 5 g of peanut shell dry powder, 1.0 g of yeast extract, (NH 4 ) 2 SO 4 0.4 g, KH 2 PO 4 0.25 g, peptone 0.1 g, MgSO 4 ·7H 20.01g, distilled water is settled to 1000mL, pH 7.0, (wherein the dry powder of peanut s...

Embodiment 3

[0042] Embodiment three, the preparation of Aspergillus niger H201KP280086 fermentation agent

[0043] The preparation process is as follows:

[0044] 1. Strain activation: inoculate the original strain of Aspergillus niger H201KP280086 strain on PDA solid medium under aseptic conditions, and activate it by culturing at 30°C for 2 days;

[0045] 2. Preparation of seed solution

[0046] The activated strains were inoculated in the seed medium under aseptic conditions, and cultured at 30°C and 180 rpm for 72 hours to obtain the seed solution.

[0047] The components of the seed medium were: glucose 20 g, yeast extract 1.0 g, (NH 4 ) 2 SO 4 0.4 g, KH 2 PO 4 0.25g, peptone 0.1g, MgSO 4 ·7H 2 O 0.01g, distilled water to 1000mL.

[0048] 3. Bacteria preparation

[0049] Inoculate the seed liquid according to the inoculum amount of 20% into a fermenter equipped with a high-temperature sterilized liquid fermentation medium, and culture it in air at 30°C for 6 days to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com