Formaldehyde absorbing agent and preparation method thereof

A formaldehyde absorbent and deacetylated chitin technology, which is applied in the field of air purification, can solve the problem of low formaldehyde absorption efficiency, and achieve the effects of improved formaldehyde absorption efficiency, good dispersion, and improved absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

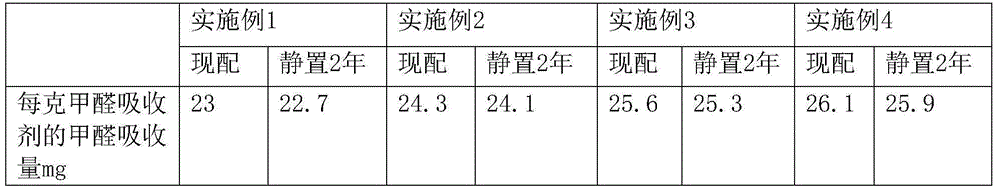

Examples

Embodiment 1

[0025] A formaldehyde absorbent, its raw material components include: 21 parts of tannic acid, 3 parts of dicumyl hydroperoxide, 16 parts of deacetylated chitin, 5 parts of iron white powder, 13 parts of calcium carbonate powder, barium stearate 6 parts, 3 parts of 10,10'-oxobisphenoxarsen, 3 parts of distarch sodium acetylated diacid, 16 parts of nitromethane, 11 parts of aniline, 6 parts of seaweed powder, 9 parts of diatomaceous earth, nano-titanium dioxide 11 parts, 5 parts of alumina and 61 parts of deionized water, the parts are parts by mass.

[0026] The preparation method of the above-mentioned formaldehyde absorbing agent comprises the following steps connected in sequence:

[0027] 1) Heat deionized water to 67°C;

[0028] 2) adding tannic acid, chitosan, iron white powder, calcium carbonate powder, seaweed powder, diatomaceous earth, nano titanium dioxide and alumina to the deionized water obtained in step 1), and mixing;

[0029] 3) Add dicumyl hydroperoxide to ...

Embodiment 2

[0031] It is basically the same as Example 1, except that the raw material components of the formaldehyde absorbent also include: 5 parts of nano-TiO2 / diatomite composite catalyst, and the said parts are parts by mass.

[0032] The preparation method of the above-mentioned formaldehyde absorbing agent comprises the following steps connected in sequence:

[0033] 1) Heat deionized water to 67°C;

[0034] 2) Add tannic acid, chitosan, iron white powder, calcium carbonate powder, seaweed powder, diatomaceous earth, nano-titanium dioxide, nano-TiO2 / diatomite composite catalyst and alumina to the deionized water obtained in step 1), mix uniform;

[0035] 3) Add dicumyl hydroperoxide to the material obtained in step 2), and after reacting at 71°C for 3.5 hours, add barium stearate, 10,10'-oxobisphenoxarsenic acid, acetylated diacid bis Starch sodium, nitromethane and aniline are added to the reaction material and mixed evenly, then the temperature is lowered and the material is di...

Embodiment 3

[0037] The raw material components of a formaldehyde absorbent include: 23 parts of tannic acid, 48 parts of kraft glue, 4 parts of dicumyl hydrogen peroxide, 18 parts of deacetylated chitin, 6 parts of iron white powder, 14 parts of calcium carbonate powder, 6 parts of barium stearate, 3 parts of 10,10'-oxobisphenoxarsenic acid, 4 parts of distarch sodium acetylated diacid, 16 parts of nitromethane, 12 parts of aniline, 7 parts of seaweed powder, 9 parts of diatomaceous earth 12 parts of nano-titanium dioxide, 6 parts of alumina, 6 parts of nano-TiO2 / diatomite composite catalyst, 12 parts of graphite powder, 4 parts of hollow glass microspheres, 9 parts of p-phenylenediamine, 5 parts of phenol, 7 parts of ferric chloride parts and 62 parts of deionized water, said parts are parts by mass.

[0038] The preparation method of the above-mentioned formaldehyde absorbing agent comprises the following steps connected in sequence:

[0039] 1) Heat deionized water to 66-68°C;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com