Light fireproof thermal-insulation building material

A technology for fireproofing and heat preservation and building materials, which is applied in the field of lightweight fireproofing and heat preservation building materials to achieve the effects of eliminating condensation, short initial setting time and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

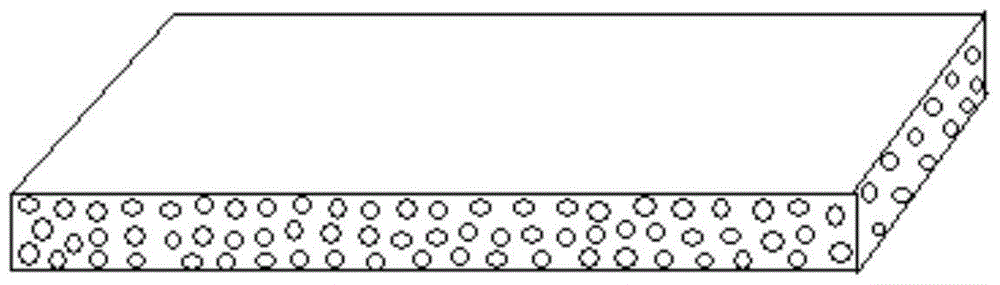

Image

Examples

Embodiment 1

[0020] A lightweight fireproof and heat-retaining building material is composed of the following components in parts by weight: 60 parts of cement, 50 parts of foam, 4 parts of modifier and 7 parts of aluminum hydroxide.

[0021] The modifier is composed of the following components in parts by weight: 50 parts of alkali metal silicate, 6 parts of 1,1-di(p-tolyl)ethylene, 1 part of graphene, 1 part of silicone oil, 1.5 parts of calcium chloride parts, 15 parts of water.

[0022] Take the above materials and mix them evenly, add 0.8 times the weight of water, dry and press to form a thermal insulation wall material with a thickness of 20cm.

[0023] Spray the above insulation wall material with a flame spray gun at 1200°C for 2 minutes, the foam material will not burn, and the temperature behind the insulation wall will remain unchanged. 1200 ℃ flame spray gun fire 10min, the foam material does not burn. Cut the insulation wall material by machine, and it can be seen that the ...

Embodiment 2

[0025] A lightweight fireproof and thermal insulation building material, which consists of the following components in parts by weight: 70 parts of cement, 50 parts of foam, 5 parts of modifier, 10-(2,5-dihydroxyphenyl)-10-hydrogen- 1 part of 9-oxa-10-phosphaphenanthrene-10-oxide, 1 part of coconut oil fatty acid, 1 part of 2,6,8-trimethyl-6-hydroxy-4 nonanone, 1 part of butyl acetate.

[0026] The modifier consists of the following components in parts by weight: 30 parts of alkali metal silicate, 3 parts of 4,4'-dibenzyl diethyl phosphate biphenyl, 2 parts of graphene, 2 parts of vegetable oil, propylene glycol 2 parts, 20 parts of water.

[0027] Spray the above insulation wall material with a flame spray gun at 1200°C for 2 minutes, the foam material will not burn, and the temperature behind the insulation wall will remain unchanged. 1200 ℃ flame spray gun fire 10min, the foam material does not burn. Cut the insulation wall material by machine, and it can be seen that the...

Embodiment 3

[0029] A lightweight fireproof and thermal insulation building material, which is composed of the following components in parts by weight: 75 parts of cement, 40 parts of foam, 3 parts of modifier, 1 part of borax, 1 part of dammar resin, and 1 part of methyl ethyl ketone oxime 1 part, 1 part of nitrogen nitrogen dimethylformamide.

[0030] The modifier is used to improve the fireproof, waterproof and adhesive properties of polystyrene foam, and consists of the following components in parts by weight: 360 parts of alkali metal silicate, 2-vinyl-8-hydroxyquinoline 3 parts, 1 part graphene, C 6 -C 12 1 part of saturated monohydric alcohol, 1 part of sulfonated polyethylene glycol, and 10 parts of water.

[0031] Spray the above insulation wall material with a flame spray gun at 1200°C for 2 minutes, the foam material will not burn, and the temperature behind the insulation wall will remain unchanged. 1200 ℃ flame spray gun fire 10min, the foam material does not burn. Cut the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com