Two-component polyurethane construction sealant

A two-component polyurethane and sealing paste technology, used in polyurea/polyurethane adhesives, adhesive types, adhesive additives, etc., can solve problems such as poor alkali resistance and water resistance, and achieve excellent aging resistance and construction. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

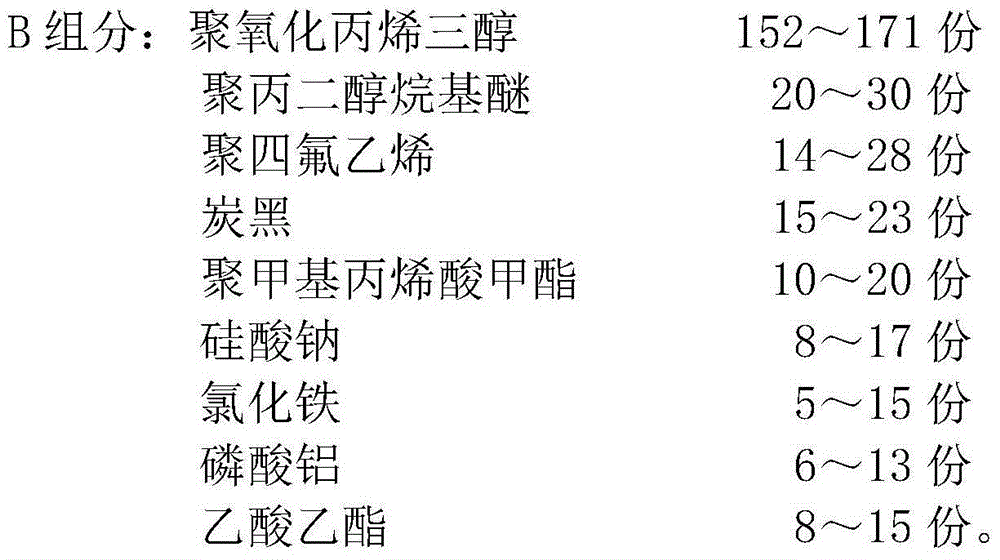

[0021] The two-component polyurethane building sealant is made of two components A and B, and each component is made of the following raw materials in parts by weight:

[0022] A component: 28 parts of diethylphenyl diisocyanate;

[0023]

[0024] The mass ratio of component A to component B is 1:1. Mix evenly and start construction.

[0025] The relative molecular mass of the polyoxypropylene triol is 3200; the relative molecular mass of the polypropylene glycol alkyl ether is 3200.

[0026] The preparation method of component B is: now add polyoxypropylene triol, polypropylene glycol alkyl ether, polymethyl methacrylate and ethyl acetate into the reaction kettle according to the above ratio, heat up and stir, and then add polytetrafluoroethylene in sequence , carbon black and sodium silicate, heat up to 90°C, turn on the vacuum pump for dehydration, keep the vacuum above 520mm mercury column, stir and dehydrate for more than 1 hour, cool down to 80°C, then add aluminum s...

Embodiment 2

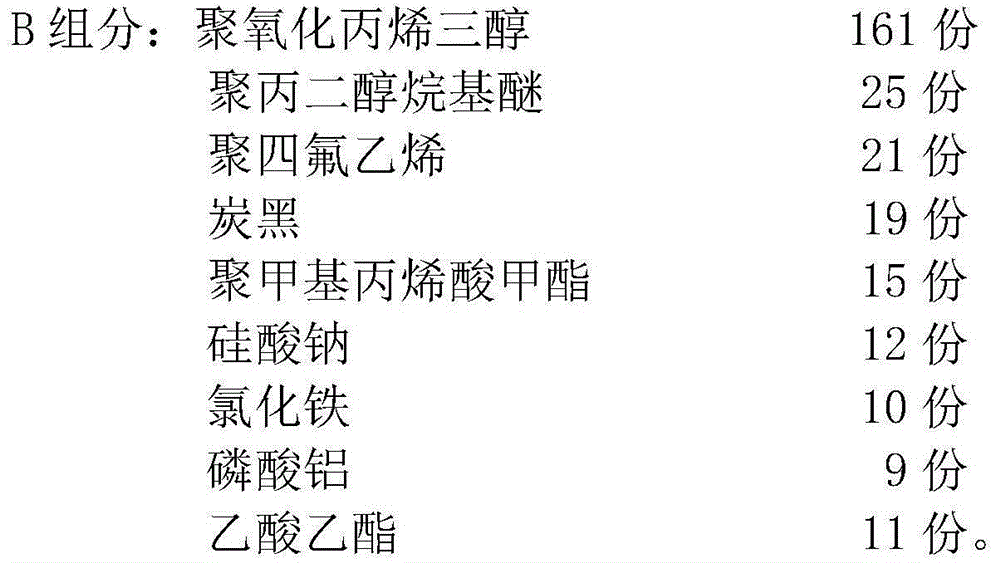

[0028] The two-component polyurethane building sealant is made of two components A and B, and each component is made of the following raw materials in parts by weight:

[0029] A component: 22 parts of diethylphenyl diisocyanate;

[0030]

[0031] The mass ratio of component A and component B is 1:1.3 and mixed evenly, then it can be applied.

[0032] The relative molecular mass of the polyoxypropylene triol is 3500; the relative molecular mass of the polypropylene glycol alkyl ether is 2800.

[0033] The preparation method of component B is: now add polyoxypropylene triol, polypropylene glycol alkyl ether, polymethyl methacrylate and ethyl acetate into the reaction kettle according to the above ratio, heat up and stir, and then add polytetrafluoroethylene in sequence , carbon black and sodium silicate, heat up to 85°C, turn on the vacuum pump for dehydration, keep the vacuum above 520mm mercury column, stir and dehydrate for more than 1 hour, cool down to 80°C, then add a...

Embodiment 3

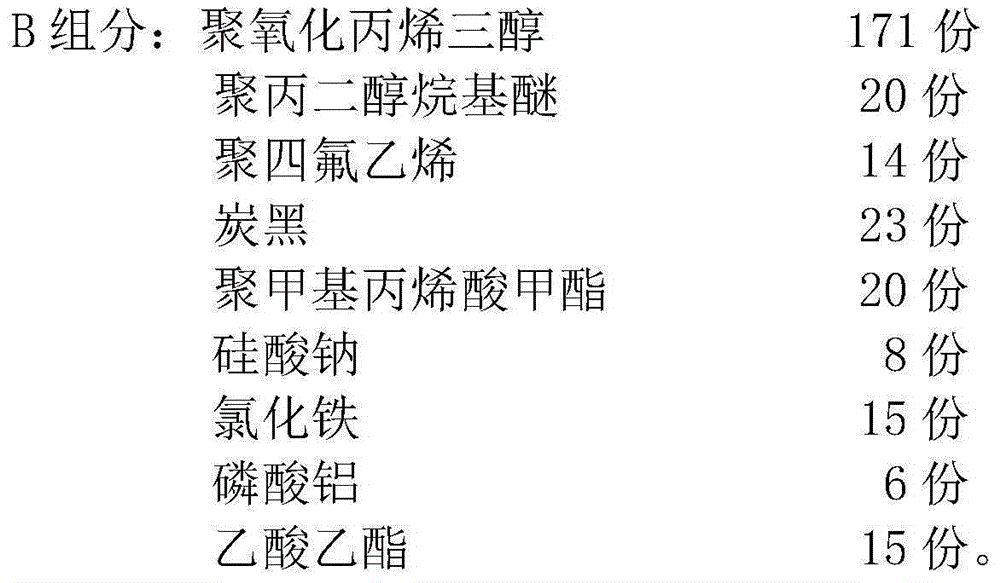

[0035] The two-component polyurethane building sealant is made of two components A and B, and each component is made of the following raw materials in parts by weight:

[0036] A component: 16 parts of diethylphenyl diisocyanate;

[0037]

[0038]

[0039] The mass ratio of component A and component B is 1:1.4 and mixed evenly, then it can be applied.

[0040] The relative molecular mass of the polyoxypropylene triol is 3700; the relative molecular mass of the polypropylene glycol alkyl ether is 2500.

[0041] The preparation method of component B is: now add polyoxypropylene triol, polypropylene glycol alkyl ether, polymethyl methacrylate and ethyl acetate into the reaction kettle according to the above ratio, heat up and stir, and then add polytetrafluoroethylene in sequence , carbon black and sodium silicate, heat up to 90°C, turn on the vacuum pump for dehydration, keep the vacuum above 520mm mercury column, stir and dehydrate for more than 1 hour, cool down to 80°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com