Chitin-cotton-blended knitted fabric for underwear

A technology of chitin cotton and knitted fabrics, applied in underwear, knitting, weft knitting and other directions, can solve the problems that have not been disclosed, and achieve the effects of improving wrinkle resistance, high anti-candida performance and good modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

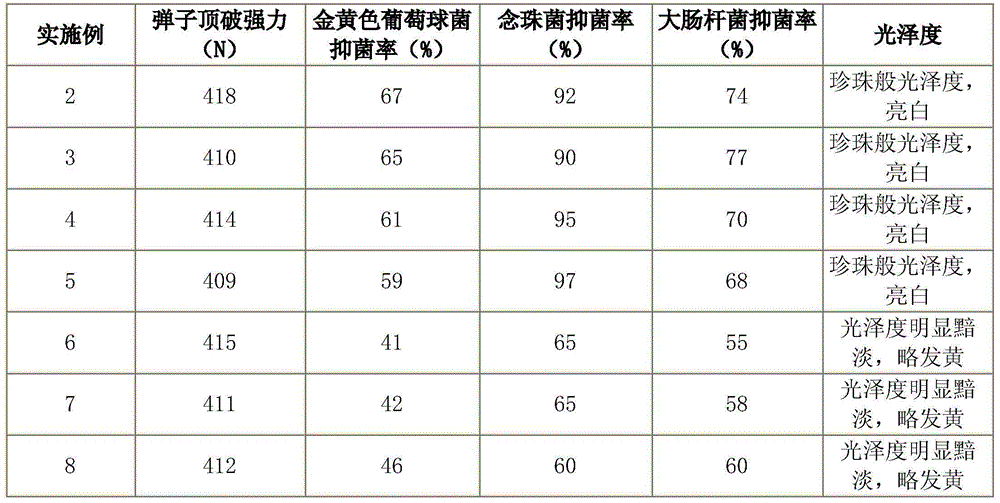

Examples

Embodiment 1

[0021] Preparation of compound bacterial agent:

[0022] Preparation of Lactococcus lactis, Bacillus coagulans, Bacillus megaterium, Sphingomonas:

[0023] Slant medium (g / L): 20 glucose, 5 yeast powder, 10 soybean peptone, 10 beef extract, 5NaCl, 10 sodium acetate, 2 ammonium citrate, 0.2MgSO4 7H2O, 0.05MnSO4 7H2O, 15 agar, pH6. 5.

[0024] Fermentation medium (g / L): 40 glucose, 10 yeast powder, 10 soybean peptone, inorganic salt (0.01NaCl, 0.5 sodium acetate, 0.2 ammonium citrate, 0.2KH2PO4, 0.2MgSO4 7H2O, 0.05MnSO4 7H2O), pH6 .5.

[0025] Fermentation method: take 1 ring on the slope and inoculate it into a 500mL shake flask with a liquid volume of 150mL, culture at 37°C and 150rpm for 24h to logarithmic phase. The cells were collected by centrifugation at 5000rpm for 10min.

[0026] The bacteria powder prepared above can also be obtained directly by purchasing.

[0027] Preparation of composite bacterial agent: Lactococcus lactis, Sphingomonas, Bacillus coagulans, and...

Embodiment 2

[0029] Production method of chitin-cotton blended knitted fabric for underwear:

[0030] (1) Preparation of composite bacterial agent: Lactococcus lactis, Sphingomonas, Bacillus coagulans, and Bacillus megaterium are formulated into composite bacterial agent;

[0031] The Lactococcus lactis, Sphingomonas, Bacillus coagulans and Bacillus megaterium are mixed according to the quantitative ratio of 1:2:2:1.

[0032] (2) Prepare fermentation medium: corn steep liquor 9g / L, trehalose 1.5g / L, vitamin C: 30ug / L, pH: 7.5; cool to 33 degrees after sterilization;

[0033] (3) Fermentation: put chitosan fibers of 1.5D*38mm into the fermentation broth, insert bacteria agent for fermentation, the inoculum amount is 1%, the fermentation temperature is 39° C., and the incubation time is 12 hours.

[0034] (4) Inactivation treatment: Take out the fabric and put it into 80°C water for 30 minutes, rinse it with clean water, and dry it at 60°C at low temperature;

[0035] (5) Preparation of ch...

Embodiment 3

[0038] Production method of chitin-cotton blended knitted fabric for underwear:

[0039] (1) Preparation of composite bacterial agent: Lactococcus lactis, Sphingomonas, Bacillus coagulans, and Bacillus megaterium are formulated into composite bacterial agent;

[0040] The Lactococcus lactis, Sphingomonas, Bacillus coagulans and Bacillus megaterium are mixed according to the quantitative ratio of 1:2:2:1.

[0041] (2) Configure fermentation culture medium: corn steep liquor 12g / L, trehalose 0.8g / L, vitamin C: 30ug / L, pH: 8.0; cool to 33 degrees after sterilization;

[0042] (3) Fermentation: put chitosan fibers of 1.5D*38mm into the fermentation broth, add inoculum agent for fermentation, the inoculum amount is 1%, the fermentation temperature is 37° C., and the incubation time is 15 hours.

[0043] (4) Inactivation treatment: Take out the fabric and put it into 80°C water for 15 minutes, rinse it with clean water, and dry it at 60°C at low temperature;

[0044] (5) Prepare c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com