Elementary substance mercury mineral adsorbent and preparation method thereof

An adsorbent and elemental mercury technology, applied in the fields of energy and environment, can solve the problems affecting the commercial value of fly ash in power plants, the limited promotion of carbon-based adsorbents, and the large amount of utilization, achieving abundant reserves, easy operation, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The solvent is: deionized water

[0032] The chemical modifier is: copper bromide

[0033] Copper bromide: medical stone (mass ratio) 1:3

[0034] Weigh 8g of copper bromide particles and put them in a reaction vessel, add 500ml of deionized water and stir with a glass rod until the solute is completely dissolved, slowly add 30g of 300 mesh medical stone ore powder during continuous stirring, and then magnetically stir at 70°C for 4 Hours, after cooling, use a vacuum filter to separate the solid from the liquid, and put the obtained solid in a drying oven at 80°C to dry for 12 hours. After drying, grind it into a 300-mesh powder to obtain a medical stone modified by copper bromide The elemental mercury mineral adsorbent, the content of copper bromide in the adsorbent is measured to be 9.12%, and the mercury removal efficiency of the adsorbent can reach 98.6%.

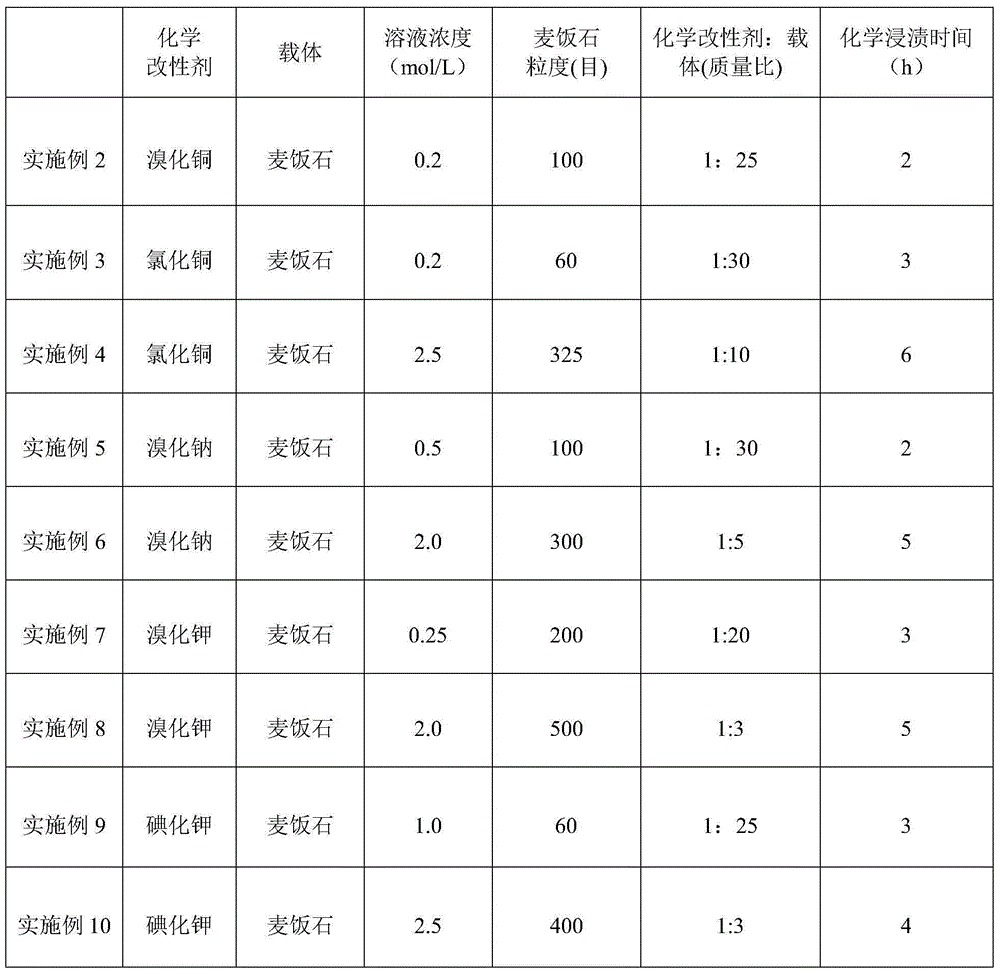

Embodiment 2~10

[0036] The chemical modifier type, proportioning and process parameters used in Examples 2-10 are as follows:

[0037]

[0038] The adsorbent preparation method used in Examples 2-10 is carried out according to the specific data shown in the above table and with reference to Example 1.

example 2

[0039] The elemental mercury mineral adsorbent obtained by copper bromide modified medical stone obtained in Example 2 has a measured copper bromide content of 0.91% in the adsorbent, and the mercury removal efficiency of the adsorbent can reach 88.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com