Method for utilizing dextran fermentation waste liquor for succinic acid fermentation production

A technology of fermenting waste liquid and dextran, which is applied in the field of bioengineering, can solve the problems of large waste of resources and difficult waste liquid treatment, and achieve the effects of reducing waste water treatment costs, reducing waste water discharge, and good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

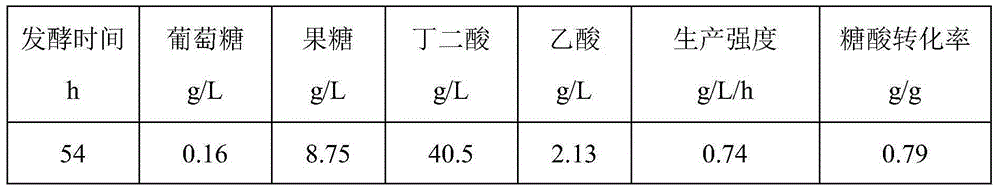

[0020] Example 1: Batch fermentation of succinic acid with dextran fermentation waste liquid as carbon source

[0021] a) Preparation of fermentation medium

[0022] Take 1.45L of dextran fermentation waste liquid (reducing sugar content detected as 61.5g / L) after about three times of concentration as the mother liquor, add other ingredients in the fermentation medium to prepare the fermentation medium, corn steep liquor 25g / L, K 2 HPO 4 1.5g / L, NaH 2 PO 4 2.2g / L, sodium glutamate 2g / L, biotin 0.01g / L, Na 2 S0.01g / L, adjust the pH to 6.2, and sterilize at 121°C for 0min.

[0023] b) Seed cultivation

[0024] Actinobacillus succinicum CCTCCNO: M2012036 The first-class seeds of the shake flask were cultured statically for 12 hours in an anaerobic incubator, and the cultivation temperature was 38°C. The first-class seeds were inserted into 150mL second-class seeds with an inoculum amount of 2.5% (volume fraction) (The composition of the seed medium is: glucose 10g / L, yeast ...

Embodiment 2

[0029]Example 2: Batch fermentation of succinic acid with dextran fermentation waste liquid as carbon source

[0030] a) Preparation of fermentation medium

[0031] Adjust the dextran fermentation waste liquid to the reducing sugar content of about 90g / L, and add corn steep liquor 35g / L, K 2 HPO 4 3g / L, NaH 2 PO 4 3g / L, sodium glutamate 0.05g / L, biotin 0.5g / L, Na 2 S0.5g / L, adjust the pH to 6.0, and make it into a fermentation medium.

[0032] b) Seed cultivation

[0033] The seed solution of Actinobacillus succinate CCTCC NO: M2012036 was prepared.

[0034] c) Succinic acid fermentation

[0035] The initial reducing sugar concentration of the fermentation medium is about 90g / L, the temperature is 37°C, the fermentation time is 50h, and the rotation speed is 150r / min. 2 CO 3 Control pH6.0-6.5, finish fermentation when the concentration of succinic acid in the fermentation broth no longer increases, the result shows that the output of succinic acid can reach 48.2g / L. ...

Embodiment 3

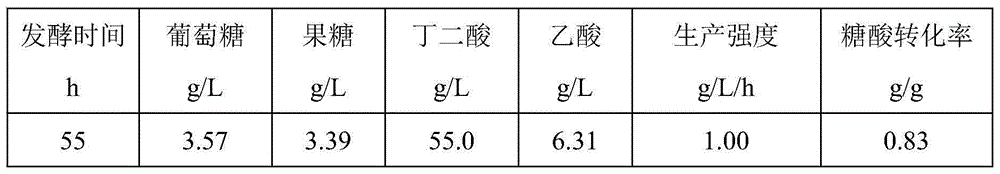

[0036] Embodiment 3: using dextran fermentation waste liquid as carbon source fed batch fermentation to produce succinic acid

[0037] a) Fermentation medium and feed preparation

[0038] Take 1.6L tap water, add other ingredients in the fermentation medium to prepare the fermentation medium, corn steep liquor 25g / L, K 2 HPO 4 2g / L, NaH 2 PO 4 2.2g / L, sodium glutamate 2g / L, biotin 0.01g / L, Na 2 S0.01g / L, glucose 30g / L, adjust the pH to 6.3, and sterilize at 121°C for 20min.

[0039] After concentrating the dextran fermentation waste liquid by about 10 times its volume (reducing sugar content in it was detected to be 305.4g / L), take 0.6L into a feeding bottle, sterilize at 115°C for 20min, and connect the feeding bottle to the fermenter after sterilization superior.

[0040] b) seed culture as described in Example 1

[0041] c) Succinic acid fermentation

[0042] The initial glucose concentration of the fermentation medium was 30g / L, the temperature was 37°C, the fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com