High-toughness gas-electric vertical welding flux-cored wire for corrosion-resistant cot steel and preparation method thereof

A flux-cored wire, gas-electric vertical welding technology, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problem of not finding welding materials, and achieve the effect of good welding process performance, good corrosion resistance, and accelerated construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056]Carbon steel strip is used as the outer skin of the welding wire, C: 0.01-0.08%; Mn: 0.1-0.4%; Si: 0.01-0.03%; S: 0.005-0.010%; P: 0.005-0.015%; the balance is iron Low-carbon steel thin strip is used as the metal sheath of the welding wire; taking the preparation and production of 100Kg welding wire as an example, the components in the flux core are: copper (Cu) powder: 0.32kg, tungsten powder: 0.06kg, antimony powder: 0.07kg, calcium fluoride : 0.58kg, sodium carbonate: 0.65kg, potassium carbonate: 0.4kg, aluminum (Al) powder: 0.08kg, electrolytic manganese: 1.3kg, ferrosilicon: 0.3kg, nickel powder: 0.55kg, iron powder: 18kg; The components in the drug core are mixed uniformly and then used;

[0057] Put the steel strip in the welding wire forming machine, inject the ready-to-use flux core mixture into the groove of the steel strip bent transversely into a "U" shape, and then roll it into wire, and then finely draw it to ¢1.6mm. .

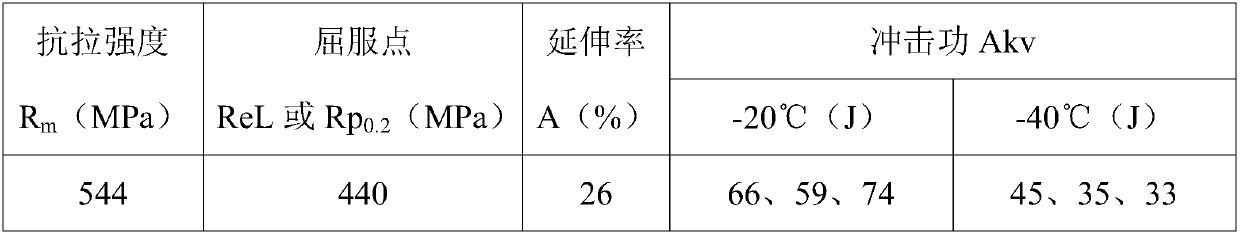

[0058] In this embodiment, weldin...

Embodiment 2

[0065] The sheath of welding wire is identical with embodiment 1, is example with preparation and production 100Kg welding wire, each composition in the flux core is: copper (Cu) powder: 0.32kg, tungsten powder: 0.06kg, antimony powder: 0.07kg, calcium fluoride: 0.6 kg, sodium carbonate: 0.65kg, potassium carbonate: 0.4kg, aluminum (Al) powder: 0.08kg, electrolytic manganese: 1.5kg, ferrosilicon: 0.3kg, nickel powder: 0.60kg, iron powder: 19kg; 1, the chemical composition of the deposited metal of the welding wire is shown in Table 3, and the mechanical properties of the deposited metal are shown in Table 4:

[0066] Table 3 Deposit metal chemical composition (wt%)

[0067] C

mn

Si

S

P

Ni

W

Sb

Cu

0.078

1.21

0.20

0.0082

0.015

0.42

0.42

0.49

0.21

[0068] The balance is Fe and impurities

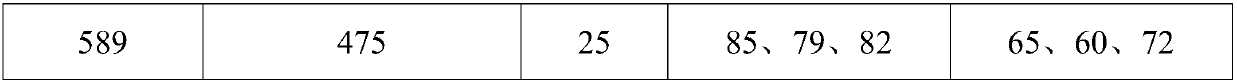

[0069] Table 4 Deposited metal mechanical properties

[0070]

[0071]

Embodiment 3

[0074] The outer skin of the welding wire is the same as in Example 1. Taking the preparation of 100Kg welding wire as an example, the components in the flux core are: copper (Cu) powder: 0.33kg, tungsten powder: 0.07kg, antimony powder: 0.07kg, calcium fluoride: 0.7 kg, sodium carbonate: 0.65kg, potassium carbonate: 0.4kg, aluminum (Al) powder: 0.09kg, electrolytic manganese: 1.7kg, ferrosilicon: 0.4kg, nickel powder: 0.7kg, iron powder: 19kg; Mix the ingredients in the mixture evenly before use;

[0075] The preparation method of this embodiment is the same as that of Example 1.

[0076] In this embodiment, the welding parameters are the same as those in Embodiment 1 except that the gas flow rate is 30 L / min. The chemical composition of the deposited metal of the welding wire is shown in Table 5, and the mechanical properties of the deposited metal are shown in Table 6:

[0077] Table 5 Chemical composition of deposited metal (wt%)

[0078] C

mn

Si

S

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com