System and method for deeply treating chemical wastewater and biochemical tail water

A technology for advanced treatment and chemical wastewater, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Level A standards, difficult large-scale engineering applications and other issues, to achieve the effect of promoting the efficiency of ozone oxidation, improving the biodegradability of wastewater, and speeding up the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

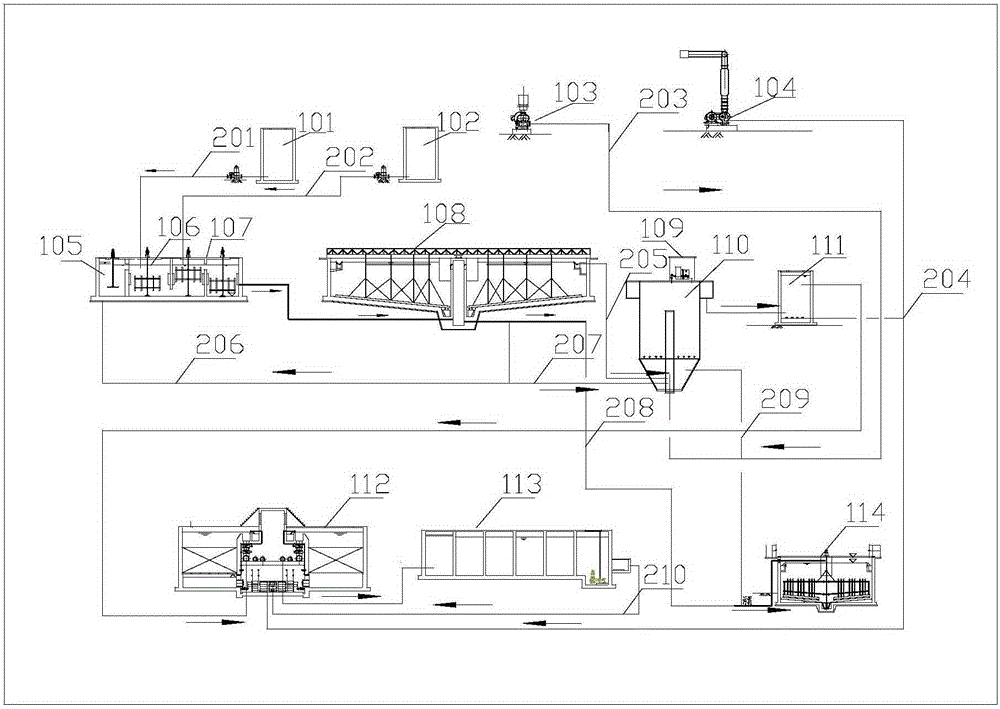

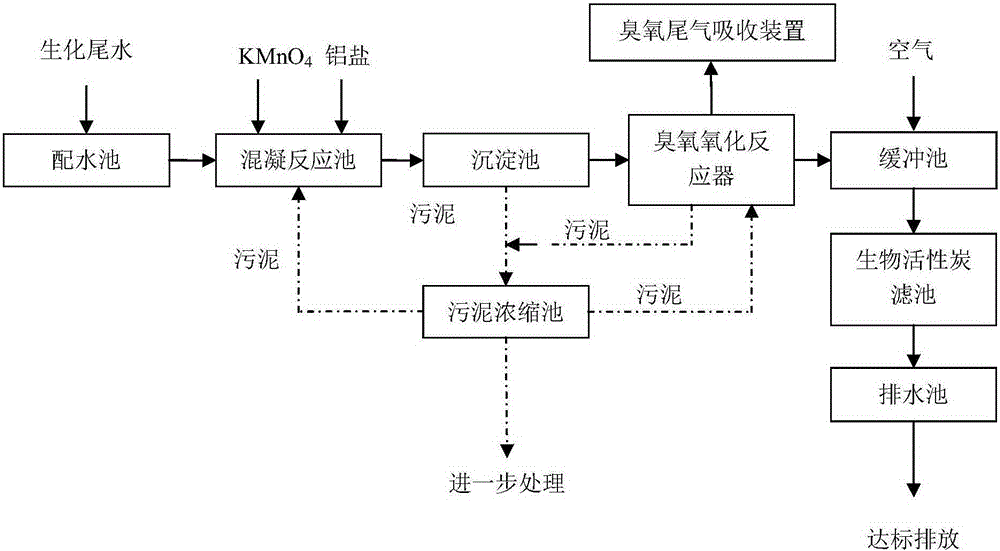

[0040] combine Attached picture , a system for the advanced treatment of chemical wastewater biochemical tail water, including a physicochemical treatment system and a biochemical treatment system (see figure 1 ), the physical and chemical treatment system includes a water distribution tank 105, a coagulation reaction tank (comprising the first grid 106 of the coagulation reaction tank and the second grid 107 of the coagulation reaction tank), a sedimentation tank 108, an ozone oxidation reactor 110, an ozone tail gas Absorption device 109, buffer pool 111; waste water in distribution pool 105 flows to the first grid 106 of the coagulation reaction tank by itself, and then enters the second grid 107 of the coagulation reaction tank in turn, and the potassium permanganate solution is added by potassium permanganate Pipe 101 and potassium permanganate dosing pipe 201 are added to the first grid 106 of the coagulation reaction tank, and the aluminum salt coagulant is added to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com