Nickel cobalt sulfide/graphene/carbon nanotube composite material and preparation method and application thereof

A technology of carbon nanotubes and cobalt-nickel sulfide, applied in the direction of electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of affecting the catalytic characteristics and energy storage cycle stability, and the active sites cannot be fully exposed, etc., to achieve The experimental design is ingenious, easy to operate, and the effect of good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment includes the following steps:

[0034] (1) Disperse 100 mg of graphene oxide in 100 mL of deionized water, and prepare a stable dispersed graphene oxide dispersion by ultrasonication.

[0035] (2) Add 50 mg of carbon nanotubes to the graphene oxide dispersion, continue to sonicate for 2 hours, and take the upper layer of black liquid by centrifugation at a centrifugal rate of 8000 rpm and a centrifugation time of 20 minutes to prepare uniform and stable graphene / carbon nanotubes Dispersions.

[0036] (3) Dissolve 232mg of cobalt nitrate, 116mg of nickel nitrate, 200mg of thiourea and 2mL of ethylenediamine in 10mL of deionized water, and sonicate for 5min to prepare a uniform salt solution.

[0037] (4) Add the prepared salt solution into 20 mL of graphene / carbon nanotube dispersion, and sonicate for 20 minutes to prepare a uniform mixed solution of salt solution and graphene / carbon nanotube dispersion.

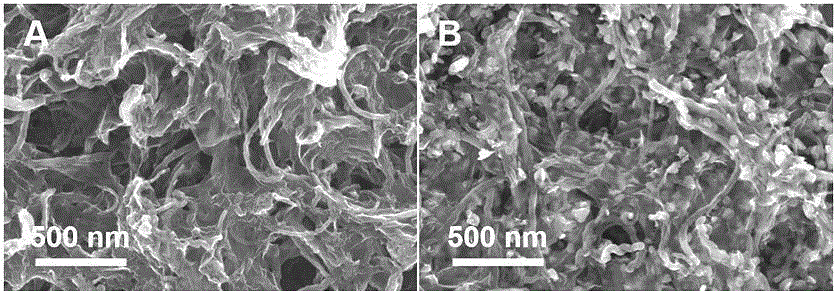

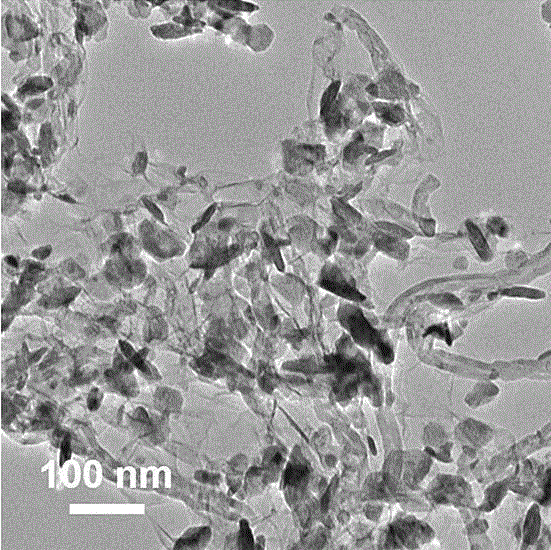

[0038] (5) Transfer the mixed solution of the p...

Embodiment 2

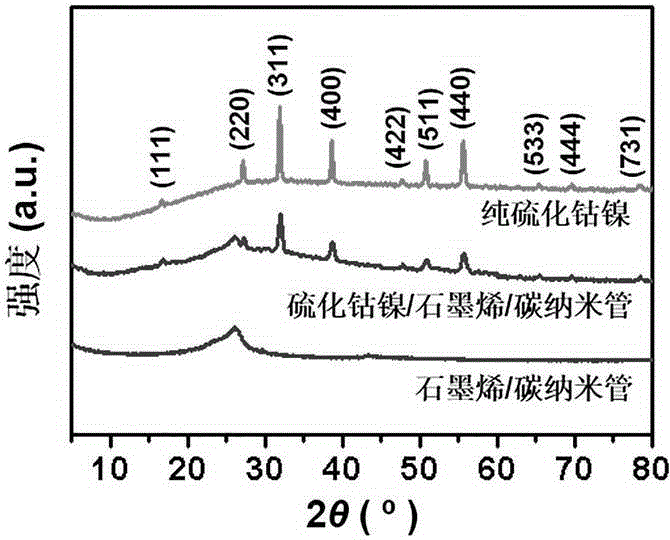

[0041] The quality of the cobalt nitrate in embodiment 1 becomes 116mg, the quality of nickel nitrate becomes 58mg, the quality of thiourea becomes 100mg, all the other are the same as embodiment 1, the composite material finally obtained is recorded as NiCo 2 S 4 / CNT / graphene-1.

Embodiment 3

[0043] The quality of the cobalt nitrate in embodiment 1 becomes 464mg, the quality of nickel nitrate becomes 232mg, the quality of thiourea becomes 400mg, all the other are the same as embodiment 1, the composite material finally obtained is recorded as NiCo 2 S 4 / CNT / graphene-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com