Method for preparing three-dimensional pore channel structure by taking wood as raw material

A three-dimensional channel and wood technology, which is applied in structural parts, carbon preparation/purification, nanotechnology for materials and surface science, etc., can solve the problem of poor electrochemical performance of battery negative electrode materials, inability to extract and embed ions, and electrolyte Difficult to penetrate and other issues, to achieve the effect of large-scale production, complete three-dimensional channel structure, and extensive commercialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

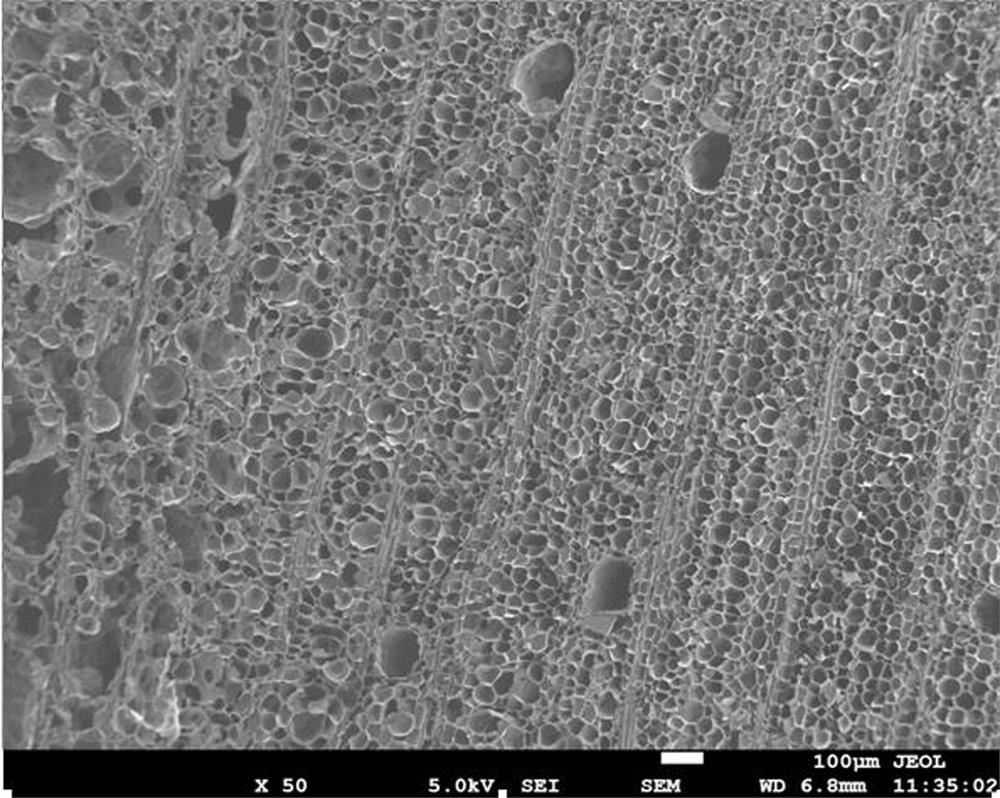

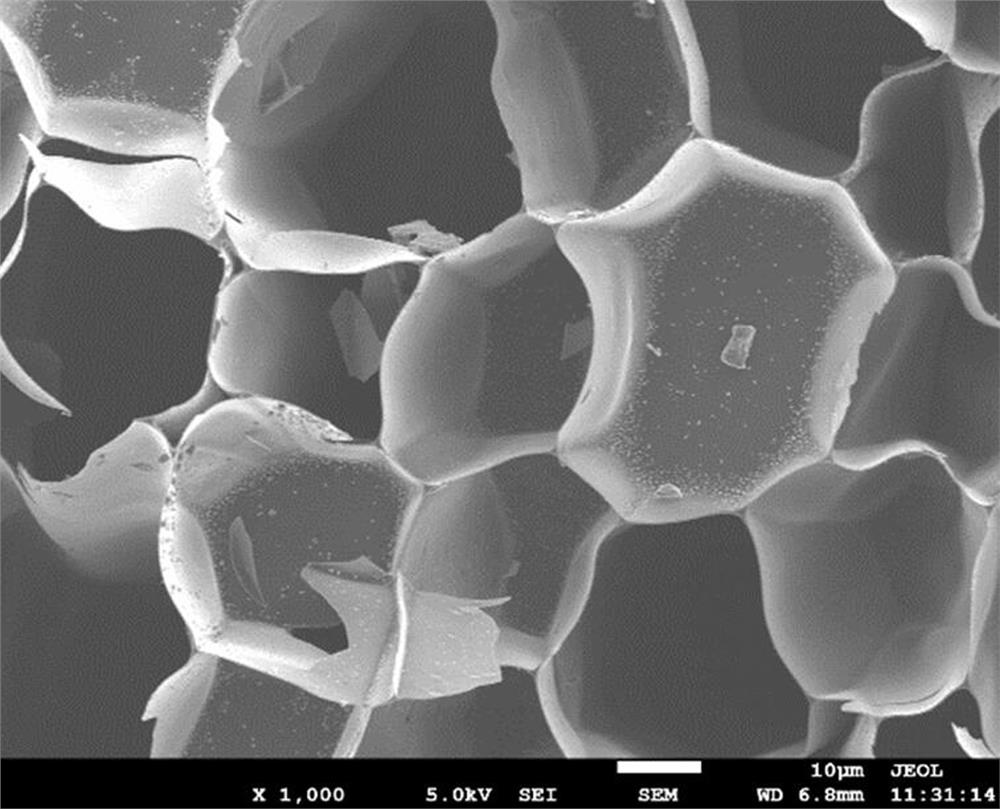

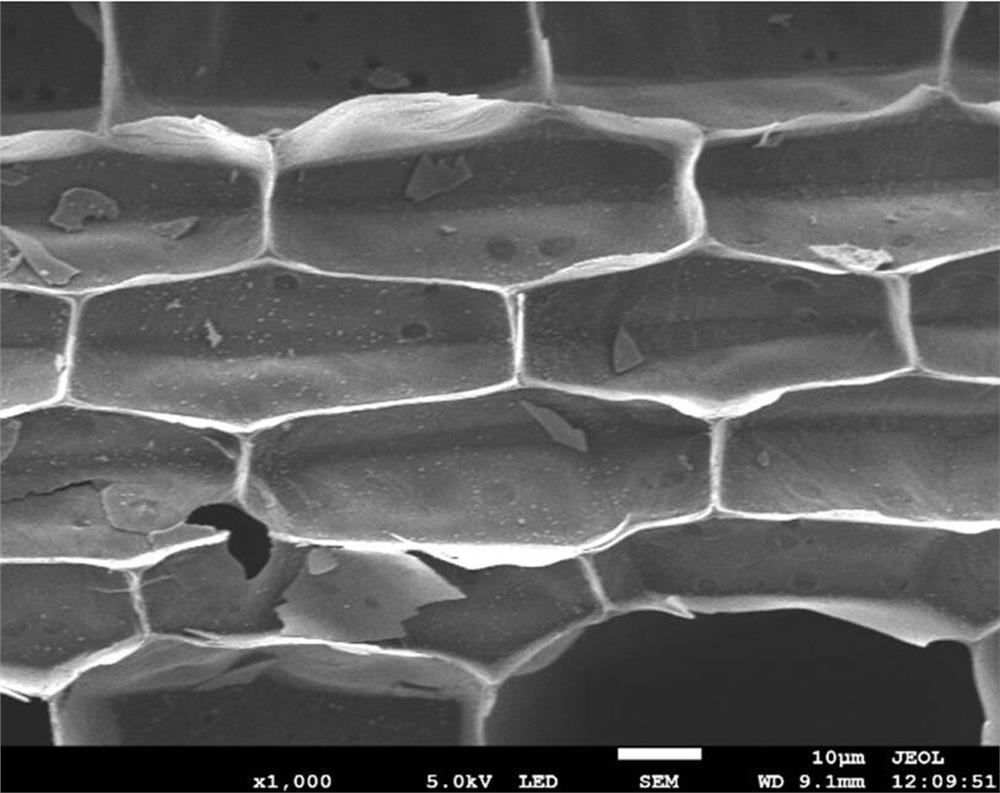

[0030] A method for preparing a three-dimensional pore structure using wood as a raw material, comprising the steps of:

[0031] (1) Preparation of precursor: Add 8g of sodium hydroxide and 10g of sodium sulfite into 150mL of distilled water, stir for 30 minutes until the solution becomes clear, and saw the dry wood along the vertical growth direction with length, width and height of 20mm, 20mm, 10mm wooden blocks, soak in the solution at room temperature for 2 hours, wash with distilled water continuously until the pH of the distilled water after cleaning is 7-8, and then dry the surface water with filter paper;

[0032] (2) Put the wood blocks treated in step (1) into the refrigerator for 12 hours, and then put them in a vacuum freeze-drying box to dry for 64 hours to remove the moisture in the wood blocks;

[0033] (3) Put the dried wood block in step (2) into a tube furnace, and anneal at 1200°C for 1 hour under an argon atmosphere at a heating rate of 10°C / min to obtain a...

Embodiment 2

[0035] A method for preparing a three-dimensional pore structure using wood as a raw material, comprising the steps of:

[0036] (1) Preparation of precursor: Add 8g of sodium hydroxide and 10g of sodium sulfite into 150mL of distilled water, stir for 30 minutes until the solution becomes clear, and saw the dry wood along the vertical growth direction with length, width and height of 20mm, 20mm, 10mm wooden blocks, soak in the solution at room temperature for 3 hours, wash with distilled water continuously until the pH of the distilled water after cleaning is 7-8, and then dry the water on the surface with filter paper;

[0037] (2) Put the wood blocks treated in step (1) into the refrigerator for 12 hours, and then put them in a vacuum freeze-drying box to dry for 64 hours to remove the moisture in the wood blocks;

[0038] (3) Put the dry wood block in step (2) into a tube furnace, and anneal at 1200°C for 1 hour at a heating rate of 10°C / min in an argon atmosphere to obtain...

Embodiment 3

[0040] A method for preparing a three-dimensional pore structure using wood as a raw material, comprising the steps of:

[0041] (1) Preparation of precursor: Add 8g of sodium hydroxide and 10g of sodium sulfite into 150mL of distilled water, stir for 30min until the solution becomes clear, and saw the dry wood along the vertical growth direction with length, width, and height of 20mm, 20mm, 10mm wooden blocks, soak in the solution at room temperature for 4 hours, wash with distilled water continuously until the pH of the distilled water after cleaning is 7-8, and then dry the water on the surface with filter paper;

[0042] (2) Put the wood blocks treated in step (1) into the refrigerator for 12 hours, and then put them in a vacuum freeze-drying box to dry for 64 hours to remove the moisture in the wood blocks;

[0043] (3) Put the dry wood block in step (2) into a tube furnace, and anneal at 1200°C for 1 hour at a heating rate of 10°C / min in an argon atmosphere to obtain a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Charging capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com