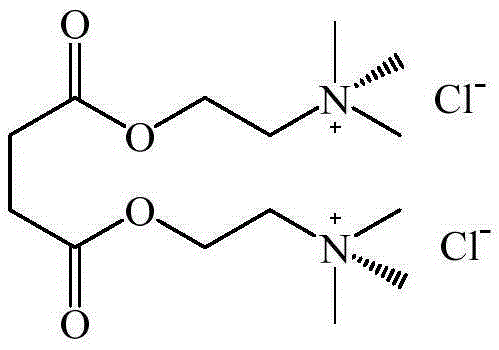

Preparation method of succinylcholine chloride

A technology of succinylcholine chloride and choline chloride, which is applied in the preparation of organic compounds, chemical instruments and methods, and the preparation of amino hydroxyl compounds, can solve the problems of serious pollution, environmental pollution, and high cost, and achieve high reaction efficiency , no sulfur dioxide pollution, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

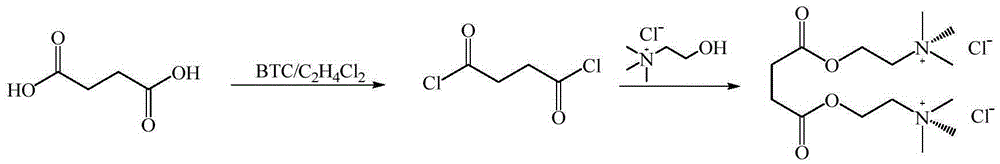

Method used

Image

Examples

Embodiment 1

[0027] Add 11.81g (0.1mol) of succinic acid, 35.43g of dichloroethane and 0.37g (0.005mol) of DMF into the three-necked flask, and slowly add BTC-C below 10°C 2 h 4 Cl 2 After adding 25ml, heat up to reflux and react for 1 hour. After the reaction is over, cool down to room temperature to obtain a dichloroethane solution of succinyl chloride; add 27.93g (0.2mol) of choline chloride to the above solution, and heat up to reflux for 30min. , Dichloroethane was recovered by distillation under reduced pressure and residual hydrogen chloride gas was removed, 23.62 g of ethanol was added, the pH of the reaction solution was adjusted to 4.5 with pyridine under stirring, cooled to below 10°C to crystallize, filtered, and dried to obtain succinylcholine chloride 31.59 g, the HPLC purity is 99.36%, and the yield is 86.87%.

Embodiment 2

[0029] Add 11.81g (0.1mol) of succinic acid, 23.62g of dichloroethane and 0.37g (0.005mol) of DMF into the three-necked flask, and slowly add BTC-C below 10°C 2 h 4 Cl 2 After adding 26.7ml, heat up to reflux for 1.5 hours. After the reaction is over, cool down to room temperature to obtain a dichloroethane solution of succinyl chloride; add 34.9g (0.25mol) of choline chloride to the above solution, and heat up to reflux to react After 20 minutes, recover dichloroethane and remove residual hydrogen chloride gas by distillation under reduced pressure, add 35.43 g of ethanol, adjust the pH of the reaction solution to 4 with pyridine under stirring, cool to below 10°C to crystallize, filter, and dry to obtain succinylcholine chloride 32.12g, HPLC purity 99.47%, yield 88.43%.

Embodiment 3

[0031] Add 11.81g (0.1mol) of succinic acid, 47.24g of dichloroethane and 0.37g (0.005mol) of DMF into the three-necked flask, and slowly add BTC-C below 10°C 2 h 4 Cl 2 After adding 26ml, heat up to reflux for 2 hours. After the reaction is over, cool down to room temperature to obtain a dichloroethane solution of succinyl chloride; add 41.88g of choline chloride to the above solution, heat up to reflux for 50 minutes, and distill under reduced pressure. Recover dichloroethane and remove residual hydrogen chloride gas, add 47.24g of ethanol, adjust the pH of the reaction solution to 4 with pyridine under stirring, cool to below 10°C to crystallize, filter and dry to obtain 32.31g of succinylcholine chloride, HPLC purity It is 99.48%, and the yield is 88.96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com