Method for preparing capacitor electrode material

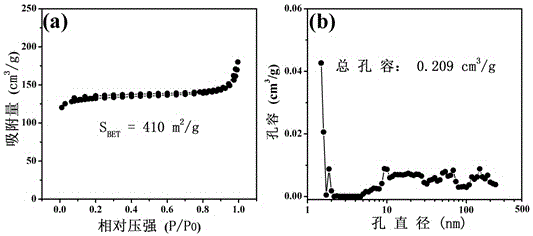

A technology of capacitor electrodes and syringes, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of no large increase in specific capacitance, harsh conditions, cumbersome steps, etc., and achieve good current charging and discharging The effect of high capacity, short process and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Weigh 1.5g of polyacrylonitrile polymer and dissolve it in 10ml of N,N dimethylformamide solution, stir for 24h until uniform and transparent.

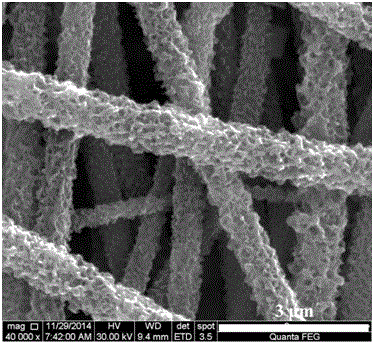

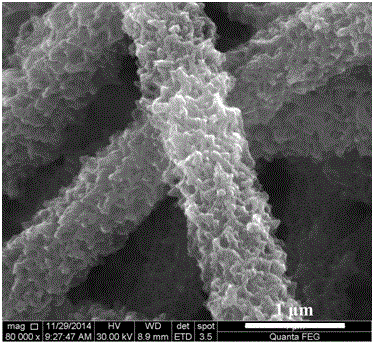

[0024] (2) Electrospinning the precursor solution in step (1) to prepare polyacrylonitrile nanofibers. Pour about 2ml of the above solution into a medical syringe each time (note: the volume of the syringe is 10ml; the length of the syringe needle is 2.5cm; the outer diameter of the syringe tip is 0.7mm). The distance between the syringe tip and the collecting plate is 15-20 cm, and the electrode voltage is 10 kV for spinning, so as to obtain a uniform polyacrylonitrile nanofiber cloth with a diameter of about 300-400 nm.

[0025] (3) Dissolve 1.5g of anhydrous ferric chloride and 0.5ml of concentrated hydrochloric acid in 30ml of deionized water and stir for 30 minutes to prepare a mixed aqueous solution of ferric chloride and hydrochloric acid. Put the polyacrylonitrile nanofiber cloth (note: 1cm*2cm) obtained in step (2...

Embodiment 2

[0029] Example 2: The difference between this example and Example 1 is that the amount of aniline monomer in step (3) is 0.2ml. Others are the same as in Example 1.

Embodiment 3

[0030] Example 3: The difference between this example and Example 1 is that the amount of aniline monomer in step (3) is 0.8ml. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com