A method and equipment for preparing synthesis gas by autothermal reforming of biogas with double risers

A double riser, autothermal reforming technology, applied in chemical instruments and methods, chemical recovery, inorganic chemistry, etc., can solve the problems of biogas reforming technology catalysts prone to carbon deposition, unfavorable downstream product synthesis, affecting synthesis gas composition, etc. , to achieve the effect of suitable industrial amplification, flexible adjustment, and improved conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

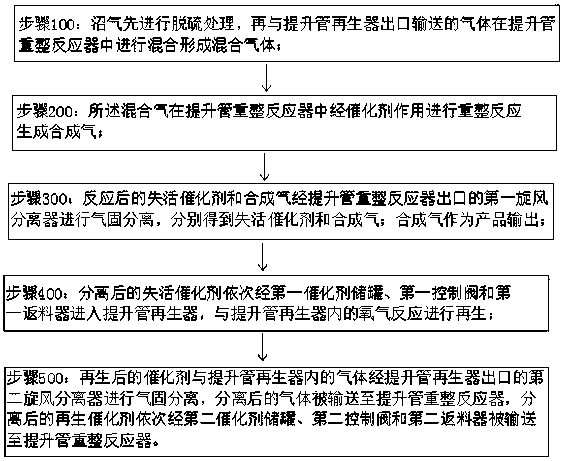

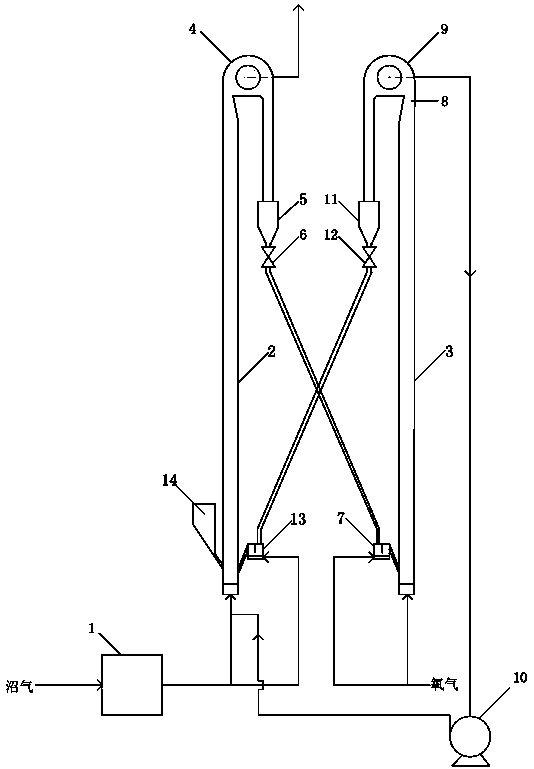

[0059] A method for preparing synthesis gas from biogas autothermal reforming with double risers, comprising the steps of:

[0060] Step 100: The biogas is first subjected to dry desulfurization for desulfurization treatment. The sulfur content of the desulfurized biogas is lower than 50ppm. The desulfurized biogas and the gas (CO 2 The mixed gas with CO) is mixed in the pipeline before entering the riser reforming reactor to form a mixed gas, and then the mixed gas enters the riser reforming reactor.

[0061] Step 200: The mixed gas is mixed with the catalyst (Ni-CeO 2 / γ-Al 2 o 3 ) contact, and carry out reforming reaction at 700°C to generate synthesis gas;

[0062] Step 300: the reacted deactivated catalyst and synthesis gas are separated from gas to solid by the first cyclone separator at the outlet of the riser reforming reactor to obtain deactivated catalyst and synthesis gas respectively; the synthesis gas is output as a product;

[0063] Step 400: The separated de...

Embodiment 2

[0066] A method for preparing synthesis gas from biogas autothermal reforming with double risers, comprising the steps of:

[0067] Step 100: The biogas is desulfurized by wet desulfurization first. The sulfur content of the desulfurized biogas is lower than 50ppm. The desulfurized biogas and the gas (CO 2 The mixed gas with CO) is mixed in the pipeline before entering the riser reforming reactor to form a mixed gas, and then the mixed gas enters the riser reforming reactor.

[0068] Step 200: The mixed gas is mixed with the catalyst (Ni-CeO 2 / γ-Al 2 o 3 ) contact, and carry out reforming reaction at 900°C to generate synthesis gas;

[0069] Step 300: the reacted deactivated catalyst and synthesis gas are separated from gas to solid through the first cyclone separator at the outlet of the riser reforming reactor to obtain deactivated catalyst and synthesis gas respectively; the synthesis gas is output as a product;

[0070]Step 400: The separated deactivated catalyst ente...

Embodiment 3

[0073] A method for preparing synthesis gas from biogas autothermal reforming with double risers, comprising the steps of:

[0074] Step 100: The biogas is desulfurized by biological desulfurization first. The sulfur content of the desulfurized biogas is lower than 50ppm. The desulfurized biogas and the gas (CO 2 The mixed gas with CO) is mixed in the pipeline before entering the riser reforming reactor to form a mixed gas, and then the mixed gas enters the riser reforming reactor.

[0075] Step 200: The mixed gas is mixed with the catalyst (Ni-CeO 2 / γ-Al 2 o 3 ) contact, and carry out reforming reaction at 800°C to generate synthesis gas;

[0076] Step 300: the reacted deactivated catalyst and synthesis gas are separated from gas to solid by the first cyclone separator at the outlet of the riser reforming reactor to obtain deactivated catalyst and synthesis gas respectively; the synthesis gas is output as a product;

[0077] Step 400: The separated deactivated catalyst e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com