Method for preparing magnetic aerogel adsorption material by using Pickering-high-internal-phase emulsion template method

A technology of high internal phase emulsion and adsorption material, applied in the field of preparation of magnetic aerogel adsorption material, can solve problems such as secondary pollution of water body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

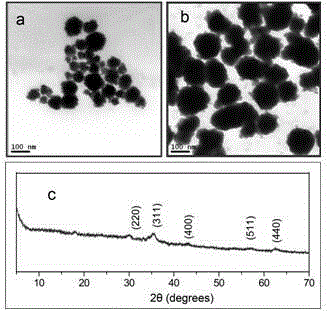

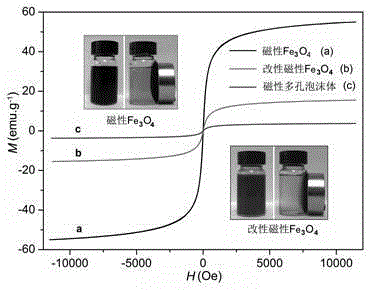

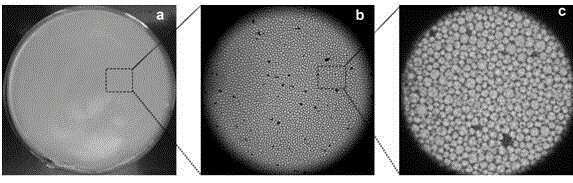

Method used

Image

Examples

Embodiment 1

[0045] 0.1g chitosan, 1.5g acrylamide, 1.5g acrylic acid, 2.2g N,N' -Methylenebisacrylamide, 0.3g modified Fe 3 o 4 , 1.5g of fatty alcohol polyoxyethylene ether surfactants were dispersed in 10mL of water; after each component was dissolved, 30mL of cyclohexane was added to the mixed solution and stirred for 4h, and 0.5g of initiator potassium persulfate was added, stirred for 5min; Pickering-high internal phase emulsion was filled into a columnar tube, sealed, and polymerized at 50°C for 12h. The obtained polymer was Soxhlet-extracted with acetone for 48 hours, dehydrated with industrial ethanol, and dried in vacuum to obtain a magnetic airgel adsorption material. The adsorption material for the heavy metal Cd 2+ and Pb 2+ The desorption amounts of 215mg / g and 486mg / g respectively.

Embodiment 2

[0047] Under stirring at 1200rpm, 0.3g chitosan, 2.0g 2-acrylamide-2-methyl-propanesulfonic acid, 1.5g acrylic acid, 1.0g ethylene glycol dimethacrylate, 0.6g modified Fe 3 o 4 , 1.0g of sorbitol fatty acid ester surfactant and 0.5g of polyoxyethylene and polyoxypropylene block copolymer surfactant were dispersed in 10mL of water; after each component was dissolved, 40mL of liquid paraffin was added dropwise to the mixed solution Stir for 2 hours, add 0.6 g of initiator ammonium persulfate, and stir for 5 minutes; the obtained Pickering-high internal phase emulsion is put into a columnar tube, sealed, and polymerized at 40°C for 24 hours. The obtained polymer was Soxhlet-extracted with n-hexane for 12 hours, dehydrated with industrial ethanol, and dried in vacuum to obtain a magnetic airgel adsorption material. The adsorption material for heavy metal Cu 2+ and Pb 2+ The desorption amounts of the desorbents were 270mg / g and 665mg / g, respectively.

Embodiment 3

[0049] Mix 1.0g chitosan, 3.0g methacrylic acid, 2.5g trimethylolpropane trimethacrylate, 1.5g modified Fe under stirring at 800rpm 3 o 4 , 2.0g of alkylphenol polyethylene oxide ether surfactants were dispersed in 15mL of water; after each component was dissolved, 55mL of p-xylene was added dropwise to the mixed solution and stirred for 3h, and 0.9g of initiator ammonium persulfate was added, Stir for 5 minutes; the resulting Pickering-high internal phase emulsion was put into a columnar tube, sealed, and polymerized at 50°C for 20 hours. The obtained polymer was Soxhlet-extracted with industrial ethanol for 24 hours, dehydrated with industrial ethanol, and dried in vacuum to obtain a magnetic airgel adsorption material. The adsorption material for the heavy metal Cd 2+ and Pb 2+ The desorption amounts of 282mg / g and 712mg / g respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com