A kind of preparation method of building decoration kiln art ceramic brick

A technology for architectural decoration and ceramic tiles, which is applied in the field of ceramics, can solve the problems of unfavorable development and high energy consumption, and achieve the effects of reducing firing costs, obvious economic benefits, and shortening firing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing architectural decorative kiln art ceramics, comprising the following steps:

[0040] A. Ingredients: Weigh the green body raw materials according to weight percentage, and the green body raw materials are composed of the following weight percentage components:

[0041]

[0042]

[0043] B. Pulping: Weigh the raw materials according to the ratio in A, and put the mixed raw materials into the ball mill according to the ratio of material: ball: water = 1: 2: 0.35; the ball mill will form a 250-mesh sieve residue of 1.2 ~ 1.7% slurry.

[0044] C. Powder making: the slurry obtained in step B is made into powder through a spray dryer, and then aged for 2 to 3 days.

[0045] D. Press molding: press the aged powder obtained in step C into brick adobe.

[0046] E. Drying: Press the powder obtained in step C into adobe, and then gradually increase the temperature to 200°C. After drying, the moisture content of the adobe is 0.5-1%, and the temperatur...

Embodiment 2

[0057] The billet is composed of the following components by weight percentage: 15% of kaolin, 12% of weathered sand, 35% of potassium feldspar, 22% of low-fired clay, and 7% of refined white sand. Waste base powder 7%, black talc 2%;

[0058] The bottom glaze is composed of the following components by weight percentage: potassium feldspar 19%, porcelain sand 10%, kaolin 10%, zinc oxide 5%, calcined talc 10%, barium carbonate 15%, dolomite 8%, calcium carbonate 11% , Calcium Phosphate 10%, Aluminum Oxide 2%

[0059] The surface glaze is composed of the following components by weight percentage: potassium feldspar 23%, porcelain sand 5%, kaolin 10%, zinc oxide 17%, calcined talc 10%, zirconium silicate 10%, titanium oxide 18%, glass powder 5% %, cobalt oxide 2%.

[0060] Other steps are the same as in Embodiment 1.

Embodiment 3

[0062] The billet is composed of the following components by weight percentage: 12% of kaolin, 10% of weathered sand, 30% of potassium feldspar, 28% of low-fired clay, and 9% of refined white sand. Waste base powder 6%, black talc 5%;

[0063] The bottom glaze is composed of the following raw materials in weight percentage: 16% albite feldspar, 15% porcelain sand, 7.5% kaolin, 6.5% zinc oxide, 7.5% calcined talc, 16% barium carbonate, 7% dolomite, 16% calcium carbonate, Calcium phosphate 5%, aluminum oxide 3.5%;

[0064] The surface glaze is composed of the following raw materials in weight percentage: 22% albite, 8% porcelain sand, 8% kaolin; 22% zinc oxide; 5% calcined talc; 15% titanium oxide, 12% zirconium silicate, and 8% glass powder , colorant 1.2%.

[0065] Other steps are the same as in Embodiment 1.

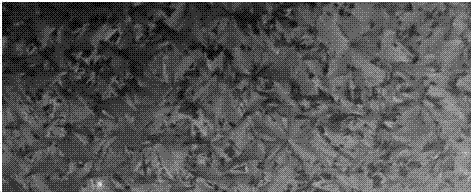

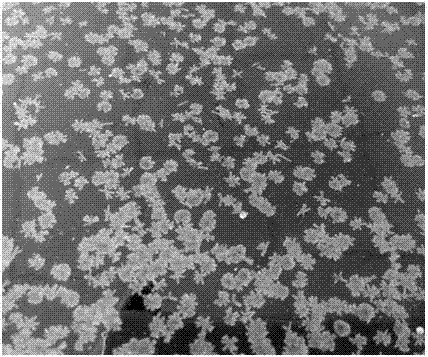

[0066] The crystal flower test results of kiln-changing artistic ceramic tiles are shown in the attached figure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com