Preparation method for silver catalyst, and silver catalyst and application thereof

A technology of silver catalysts and additives, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., to achieve the effect of improving activity and selectivity and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

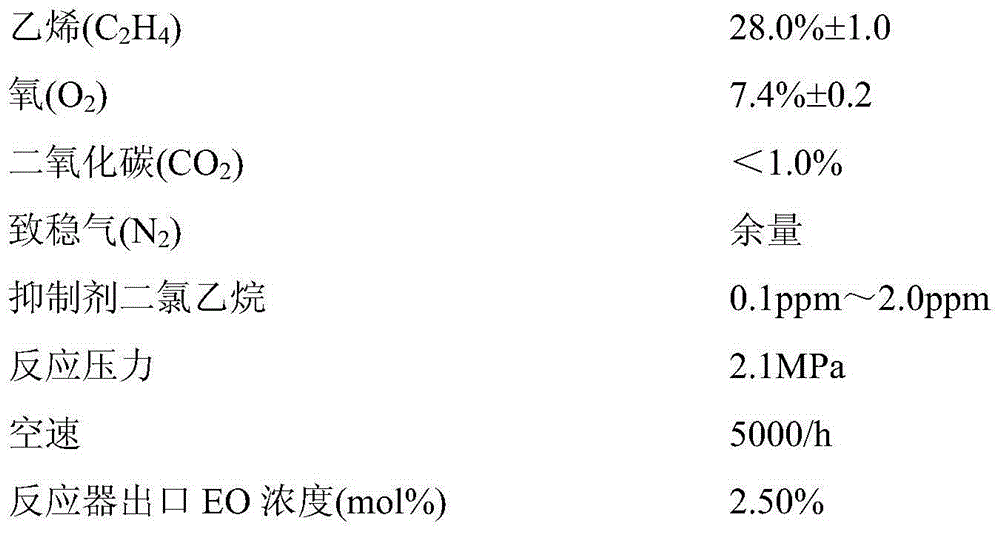

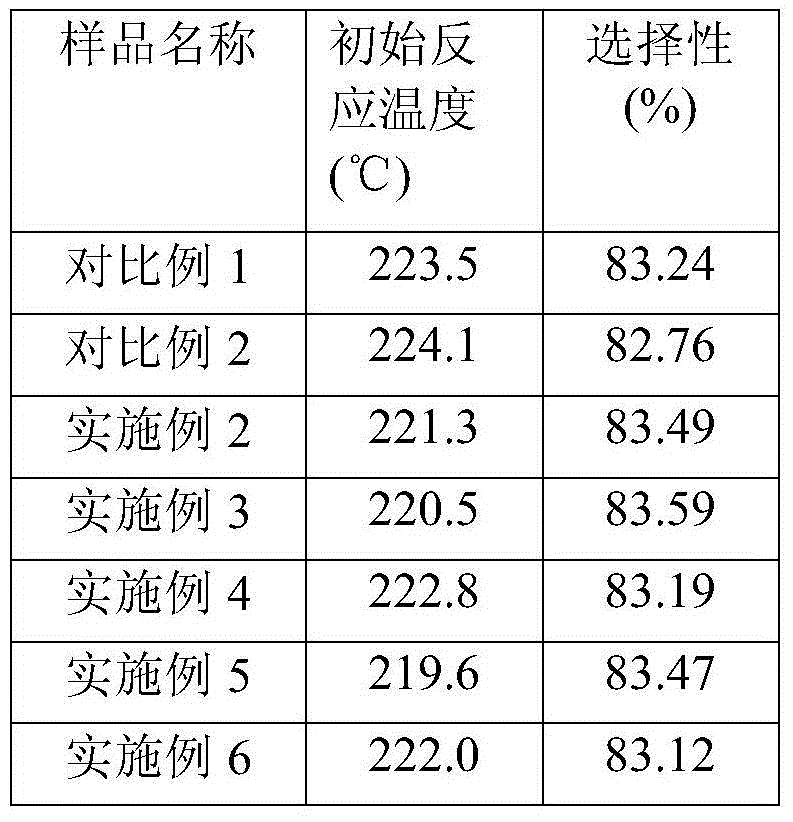

Examples

Embodiment 1

[0053] Embodiment 1: the preparation of carrier

[0054] Mix 50~500mesh trihydrate α-A1 2 o 3 4800g, fake monohydrate A1 passed through 200 mesh sieve 2 o 3 1200g, NH 4 F150g, 54g of magnesium nitrate and 21g of barium sulfate are put into the mixer and mixed evenly, then transferred to the kneader, add 42g of petroleum jelly and 2100ml of dilute nitric acid (nitric acid: water = 1:3, weight ratio), and knead to make it extrudable of paste. Extrude into a five-hole column with an outer diameter of 8.0mm, a length of 6.0mm, and an inner diameter of 1.0mm, and dry it at 80-120°C for more than 2 hours to reduce the free water content to below 10%. Put the kneaded carrier into a bell kiln, raise it from room temperature to 1280° C. over 33 hours, and calcinate at 1280° C. for 10 hours to obtain a white carrier.

Embodiment 2

[0056] 8.70g ethylenediamine and 2.94g ethanolamine are dissolved in 18.06g deionized water, and silver oxalate is slowly added in the mixed solution under stirring, and the add-on of silver oxalate makes the silver content be 26% (by weight) count). After the silver amine solution is prepared, 0.068g of cesium sulfate and 0.034g of methyl rhenium trioxide are added to prepare the impregnating solution. Take 15g of the carrier sample and put it into a flask. After vacuuming, introduce the impregnation solution to soak the carrier, and then leaching and thermal decomposition at 300°C for 3 minutes to obtain the finished silver catalyst.

Embodiment 3

[0058] Dissolve 0.034g of methyl rhenium trioxide in 50g of deionized water as impregnating solution 1; then dissolve 8.70g of ethylenediamine and 2.94g of ethanolamine in 18.06g of deionized water, and slowly add silver oxalate into the mixture while stirring, The silver oxalate is added in such an amount that the silver content in the final dipping solution is 26% (by weight). After the preparation of the silver amine solution is completed, 0.068 g of cesium sulfate is added to prepare the second dipping solution. Take 15g of the carrier sample and put it into a flask. After vacuuming, introduce impregnating solution 1 to soak the carrier. After leaching and drying at 120°C for 30 minutes, soak the carrier loaded with rhenium additives with immersion solution 2, and then leaching and 300°C. After thermal decomposition at ℃ for 3 minutes, the finished silver catalyst was obtained. The content of silver in the silver catalyst is 18±1wt%, the content of alkali metal promoter i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com