High-power-factor zinc oxide thermoelectric material and preparation method therefor

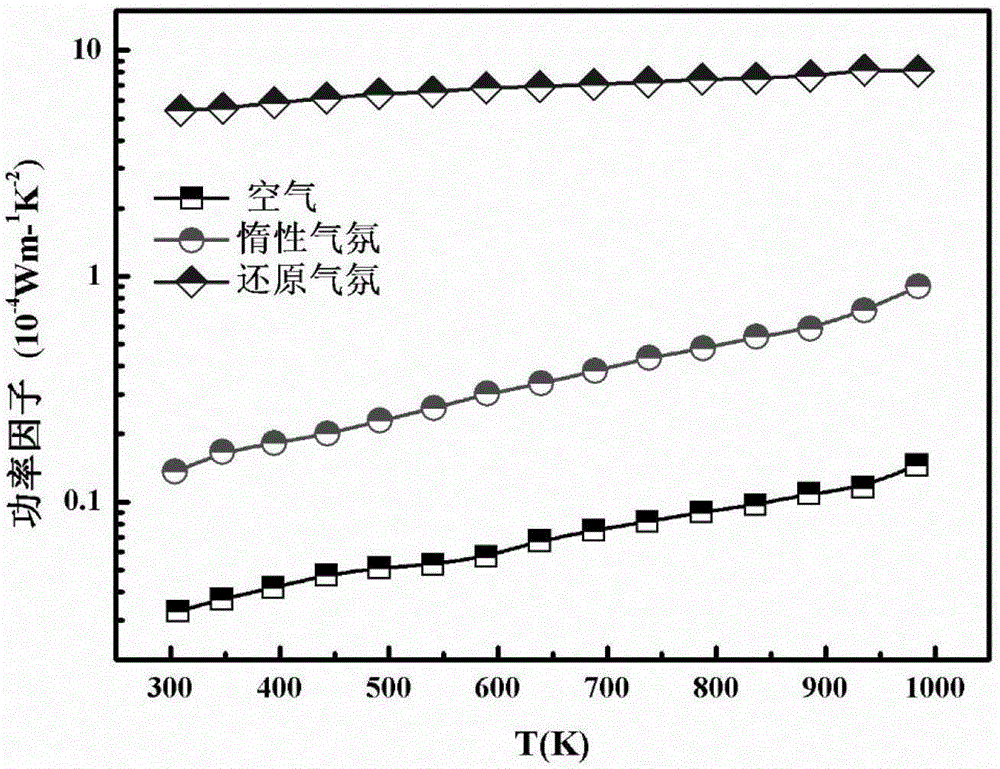

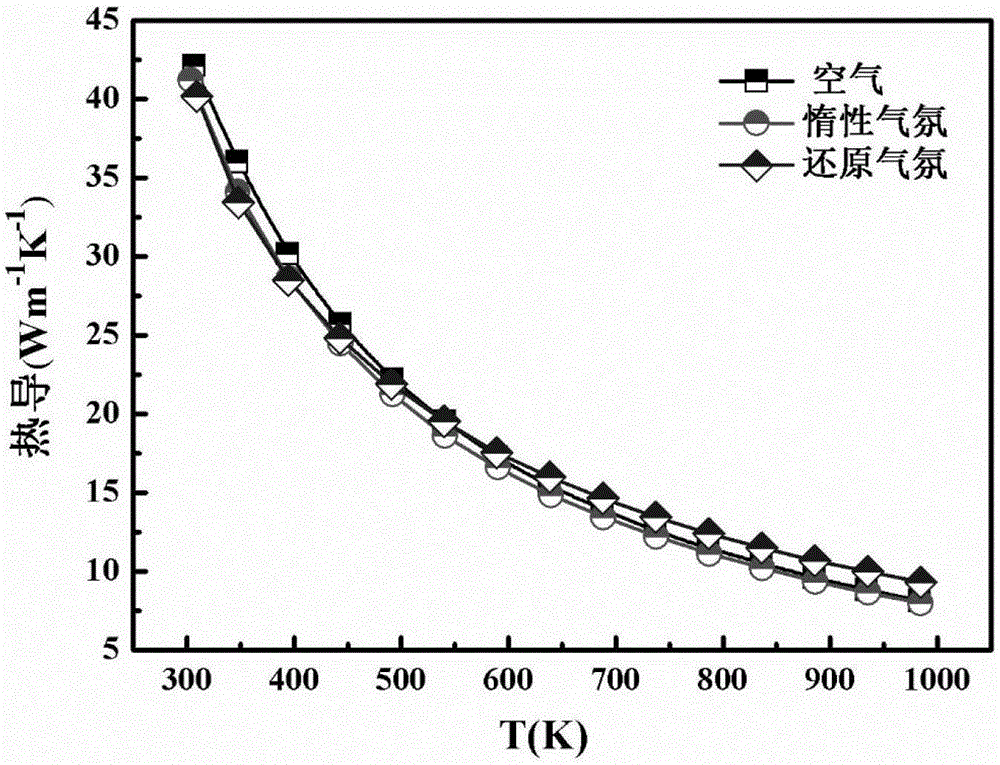

A technology of thermoelectric materials and zinc oxide, which is applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problem of not significantly reducing thermal conductance, etc., and achieve constant thermal conductance, strong practicability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The formula of this embodiment is as follows:

[0028] ZnO(98.6wt%), Al 2 o 3 (0.3wt%),MgO(0.5wt%),TiO 2 (0.6wt%)

[0029] Put the above materials together into a nylon tank, use zirconia balls or stainless steel balls, and use water as the medium for wet grinding in a planetary ball mill, with a rotation speed of 500rpm, a material-to-ball ratio of 10:1, and ball milling for 8 hours; bake the slurry at 120°C After drying, calcinate at 450°C for 2 hours to obtain composite powder; then add 10% PVA binder, artificially granulate, and then press out a green body with a diameter of 12mm; after molding, deglue, in a mixed atmosphere composed of nitrogen and carbon monoxide Under the protection of the environment, the ceramic green body was raised from room temperature to 1200 °C at a rate of 3 °C / min, kept for 2 hours and then cooled with the furnace to obtain a dense ZnO ceramic material.

[0030] After testing, the Oxford energy spectrum test shows that ZnO with high ...

Embodiment 2

[0032] The formula of this embodiment is as follows:

[0033] ZnO(99.7wt%), Al 2 o 3 (0.1wt%),MgO(0.1wt%),TiO 2 (0.1wt%)

[0034] Put the above materials together into a nylon tank, use zirconia balls or stainless steel balls, and use water as the medium for wet grinding in a planetary ball mill, with a rotation speed of 500rpm, a material-to-ball ratio of 10:1, and ball milling for 8 hours; bake the slurry at 120°C After drying, calcinate at 450°C for 2 hours to obtain composite powder; then add 10% PVA binder, artificially granulate, and then press out a green body with a diameter of 12mm; after molding, deglue, in a mixed atmosphere composed of nitrogen and carbon monoxide Under the protection of the environment, the ceramic green body was raised from room temperature to 1200 °C at a rate of 3 °C / min, kept for 2 hours and then cooled with the furnace to obtain a dense ZnO ceramic material.

[0035] ZnO with high Al solid solubility (0.7at%) can be obtained, and the carr...

Embodiment 3

[0037] The formula of this embodiment is as follows:

[0038] ZnO(97.2wt%),Al 2 o 3 (1wt%),MgO(0.8wt%),TiO 2 (1wt%)

[0039] Put the above materials together into a nylon tank, use zirconia balls or stainless steel balls, and use water as the medium for wet grinding in a planetary ball mill, with a rotation speed of 500rpm, a material-to-ball ratio of 10:1, and ball milling for 8 hours; bake the slurry at 120°C After drying, calcinate at 450°C for 2 hours to obtain a composite powder; then add 10% PVA binder, artificially granulate, and then press out a green body with a diameter of 12mm; after molding, deglue, in a mixed atmosphere composed of nitrogen and carbon monoxide Under the protection of the environment, the ceramic green body was raised from room temperature to 1200 °C at a rate of 3 °C / min, kept for 2 hours and then cooled with the furnace to obtain a dense ZnO ceramic material.

[0040] ZnO with high Al solid solubility (2at%) can be obtained, and the carrier c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com