Preparation method of magnesium oxide coated lithium nickel manganese cobalt cathode material

A technology of nickel cobalt lithium manganate and cathode material, applied in battery electrodes, electrochemical generators, structural parts, etc., can solve the problems of difficulty in obtaining impurity-free materials, reduction in comprehensive electrical properties, and difficulty in drying and removing water. , to achieve good economic benefits and market promotion value, high tap density, and the effect of reducing production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

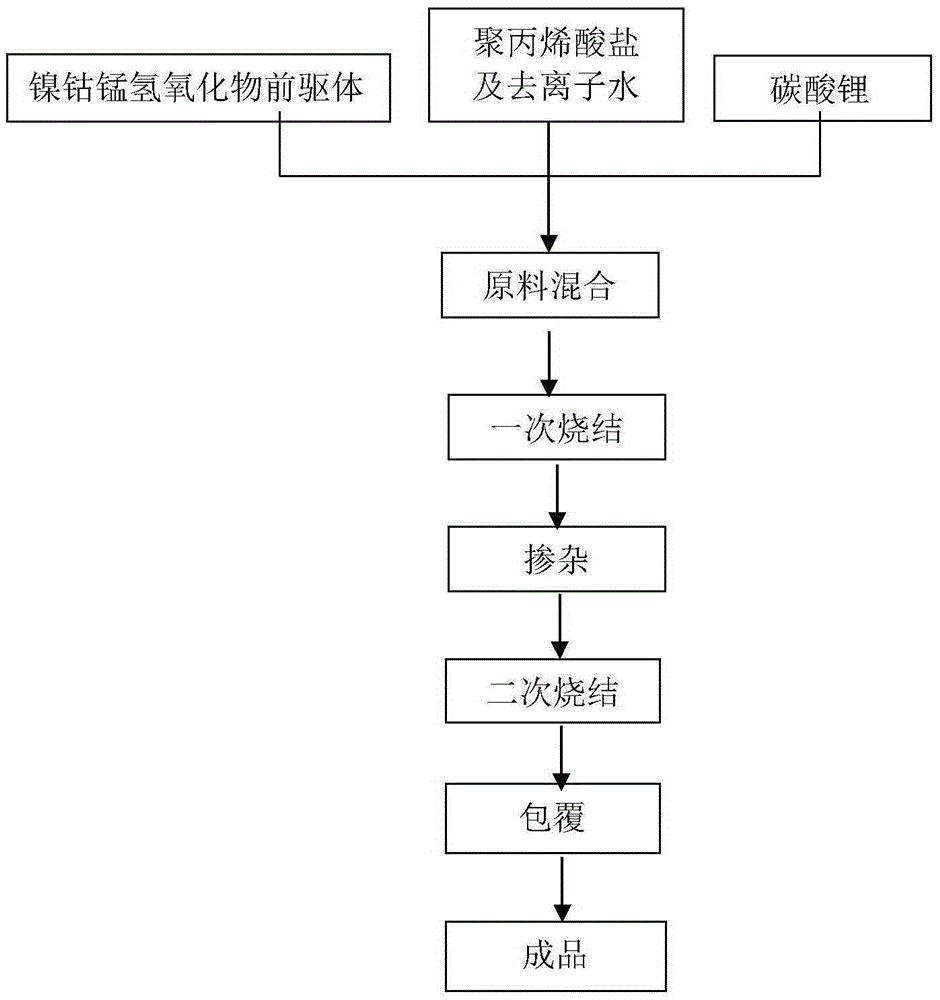

[0029] A method for preparing magnesium oxide-coated nickel-cobalt lithium manganese oxide cathode material, comprising the following steps:

[0030] (1) Mixing of raw materials: Weigh lithium carbonate, nano-spherical nickel-cobalt-manganese hydroxide precursor and sodium polyacrylate accounting for 0.2% of the total mixture mass ratio according to a molar ratio of 1:0.53, and add deionized water to make the slurry Disperse, mix and filter with a solid content of 40% to form a uniform intermediate mixture;

[0031] (2) Primary sintering: put the intermediate mixture obtained in step (1) into a sagger, send it into a pusher kiln for sintering, and produce nickel-cobalt-lithium manganese oxide material. The sintering process is filled with oxygen continuously, and the sintering temperature is 650 ℃, the sintering time is 3h;

[0032] (3) Doping: select nano-scale ZnO, carry out doping treatment to the nickel-cobalt lithium manganate obtained in step (2), and add the nickel-cob...

Embodiment 2

[0036] (1) Mixing of raw materials: Weigh lithium carbonate, nano-spherical nickel-cobalt-manganese hydroxide precursor and sodium polyacrylate accounting for 0.1% of the total mixture mass ratio by molar ratio 1:0.535, and add deionized water to make the slurry Disperse, mix and filter with a solid content of 50% to form a uniform intermediate mixture;

[0037] (2) Primary sintering: put the intermediate mixture obtained in step (1) into a sagger, send it into a pusher kiln for sintering, and produce nickel-cobalt-lithium manganese oxide material. The sintering process is filled with oxygen continuously, and the sintering temperature is 700 ℃, the sintering time is 3h;

[0038] (3) Doping: select nanoscale MgO, carry out doping treatment to the nickel-cobalt lithium manganate obtained in step (2), and add the nickel-cobalt lithium manganate obtained in step (2) to account for 0.5% of the total solid mass In, and add the polyurethane ball that specific gravity is 1.4 as mixin...

Embodiment 3

[0042](1) Mixing of raw materials: Weigh lithium carbonate, nano-spherical nickel-cobalt-manganese hydroxide precursor and potassium polyacrylate accounting for 0.2% of the total mixture mass ratio according to the molar ratio of 1:0.55, and add deionized water to make the slurry The solid content is 60% for dispersion, mixing and filtration to form a uniform intermediate mixture;

[0043] (2) Primary sintering: put the intermediate mixture obtained in step (1) into a sagger, and send it into a pusher kiln for sintering to produce nickel-cobalt-lithium manganate material. The sintering process is filled with oxygen continuously, and the sintering temperature is 750 ℃, the sintering time is 5h;

[0044] (3) Doping: choose nano-scale Al 2 o 3 , the nickel-cobalt lithium manganese oxide gained in step (2) is doped, and added in the nickel-cobalt lithium manganese oxide gained in step (2) to account for 0.2% of the total solid mass, and adding a polyurethane ball with a specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com