Method for preparing silver/cadmium sulfide/titanium dioxide composite photocatalytic material

A technology of composite photocatalysis and titanium dioxide, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of limiting TiO2 photocatalytic activity and application prospects, and achieve stable physical and chemical properties, photo The effect of high catalytic activity and high refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

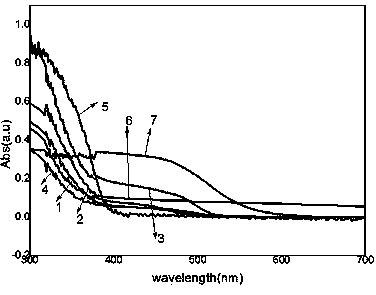

[0022] (1) CdO / TiO 2 Preparation of:

[0023] Weigh 1.0 g of triblock copolymer Pluronic P123, dissolve it in 15 ml of absolute ethanol, stir at room temperature for 0.5 h, then sonicate for 10 min to form a P123 / EtOH mixed solution, and at the same time, dissolve 3.2 ml of concentrated Hydrochloric acid was added dropwise in 4.0g of tetra-n-butyl titanate, and 0.0225g of Cd(NO 3 ) 2 4H 2 O, making the prepared CdO / TiO 2 The mass ratio of P123 / EtOH was 1%, and the P123 / EtOH mixed solution was stirred for 0.5 h and mixed with the above solution, and stirred at room temperature for at least 3 h. Pour the synthesized sol solution into an open petri dish, keep the surrounding humidity at 50%-60%, and let it stand at room temperature for 2-4 weeks. After it becomes a wet powder, calcinate it at 200°C for 4 hours and then grind it. , reflux the powder in an aqueous solution of ethylenediamine with a pH of 11-12 for 48 hours, keep the temperature at 125°C, adjust the pH at 11-12...

Embodiment 2

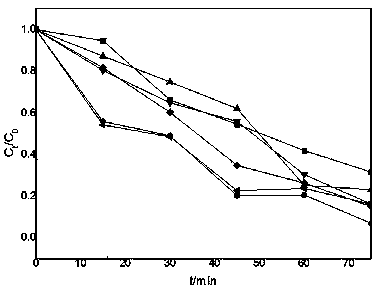

[0029] CdO / TiO 2 The preparation is the same as step (1) in Example 1, adding 0.0451g of Cd(NO 3 ) 2 4H 2 O, making the prepared CdO / TiO 2 The mass ratio is 2%; weigh 0.6g of prepared CdO / TiO 2 , CdS / TiO 2 The preparation method of the intermediate composite powder is the same as that of step (2) in Example 1, with 0.0224g of Na 2 S·9H2 O is made into 100ml of 0.2mol / L Na 2 S solution to prepare CdS / TiO 2 Intermediate composite powder, take 50mgCdS / TiO 2 It is used to degrade 50ml10PPm methyl orange solution under simulated sunlight, and the degradation rate reaches 98.6% after 75min.

[0030] All the other are with embodiment 1.

Embodiment 3

[0032] CdO / TiO 2 The preparation is the same as step (1) in Example 1, adding 0.0902g of Cd(NO 3 ) 2 4H 2 O, making the prepared CdO / TiO 2 The mass ratio is 4%; weigh 0.6g of prepared CdO / TiO 2 , CdS / TiO 2 The preparation method of the intermediate composite powder is the same as that of step (2) in Example 1, with 0.0449g of Na 2 S·9H 2 O is made into 100ml of 0.2mol / L Na 2 S solution to prepare CdS / TiO 2 Intermediate composite powder, take 50mgCdS / TiO 2 It is used to degrade 50ml10PPm methyl orange solution under simulated sunlight, and the degradation rate reaches 73.7% after 75min.

[0033] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com