Preparation method and application of waterborne polyurethane film based on phthalic anhydride polyester polyalcohol

A technology of phthalic anhydride polyester polyol and phthalic anhydride polyester, which is applied in the field of organic membranes, can solve the problem of low benzene/cyclohexane separation factor, and achieve the effects of avoiding easy yellowing, high selectivity, and ensuring affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

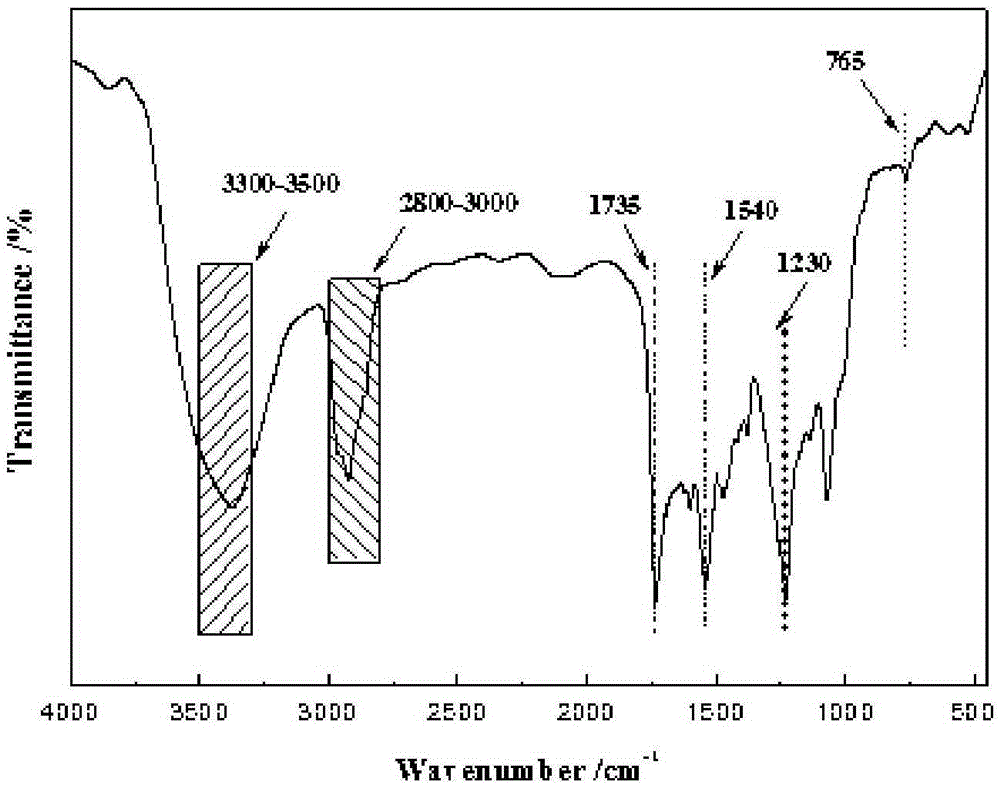

Embodiment 1

[0031] Polyphthalate-1,6-hexanediol (molecular weight: 2000) 15.03g, isophorone diisocyanate 7.4g, dimethylol propionic acid 1.1g, 1,4-butanediol 0.45 g, 0.17g of trimethylolpropane and 1 drop of catalyst dibutyltin dilaurate (about 0.05g) are stirred evenly in a three-necked flask equipped with a reflux condenser and a thermometer, and the stirring speed is kept at about 60-100rpm, and the reaction is stirred at 30°C After 2 hours, the temperature was raised to 75°C for 5 hours, the temperature was lowered to 40°C, 0.83 g of triethylamine was added, and the mixture was reacted at 40°C for 15 minutes. While stirring the product rapidly (stirring speed is about 200-300rpm), add 220g of deionized water at 10°C. Keep the stirring speed at 200-300rpm and mix for 10 minutes, add 0.3g of ethylenediamine as a chain extender to obtain a phthalic anhydride-based polyester polyol water-based polyurethane emulsion, and the solid content of the emulsion is about 10%. The emulsion was sal...

Embodiment 2

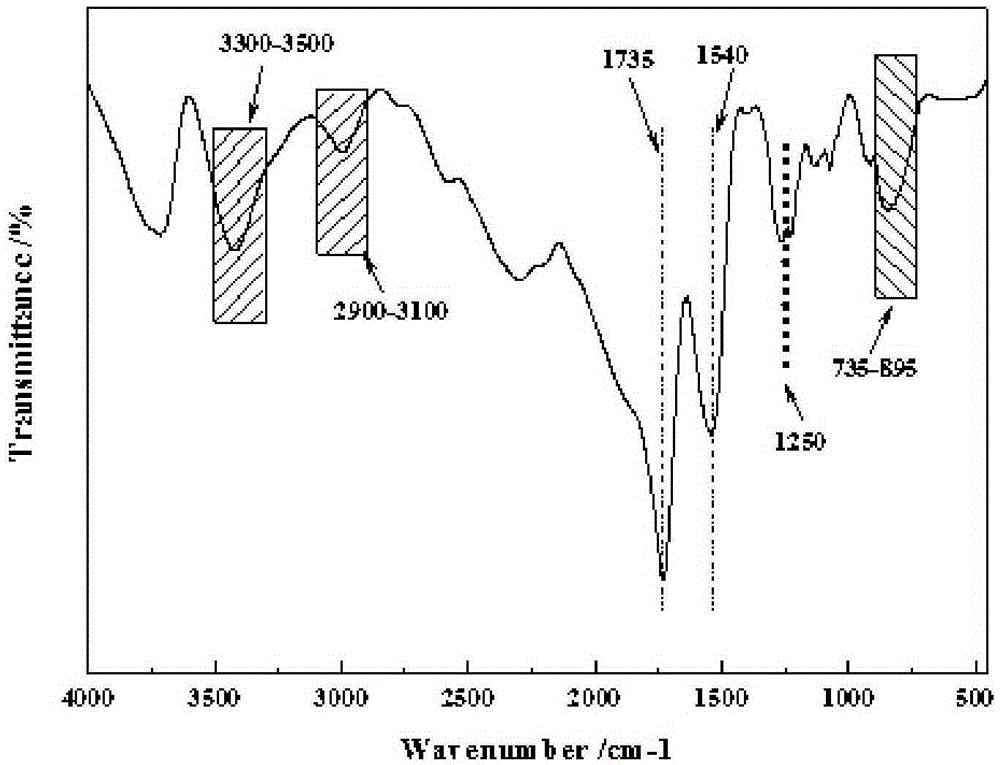

[0034] 21.69g of polyphthalate-1,6-hexanediol (molecular weight 2000), 7.4g of isophorone diisocyanate, 1.21g of dimethylol butyric acid, 0.15g of 1,4-butanediol g, 0.17g of trimethylolpropane and 1 drop of catalyst dibutyltin dilaurate (about 0.05g) are stirred evenly in a three-necked flask equipped with a reflux condenser and a thermometer, and the stirring speed is kept at about 60-100rpm, and the reaction is stirred at 40°C 1h, the temperature was raised to 85°C for 3h, the temperature was lowered to 30°C, 0.83g of triethylamine was added, and the reaction was carried out at 30°C for 30min. While stirring the product rapidly (stirring speed is about 200-300rpm), 95g of deionized water at 5°C was added. Keep the stirring speed at 200-300rpm and mix for 10 minutes, add 0.3g of ethylenediamine as a chain extender to obtain a phthalic anhydride-based polyester polyol water-based polyurethane emulsion, and the solid content of the emulsion is about 25%. The emulsion was saliv...

Embodiment 3

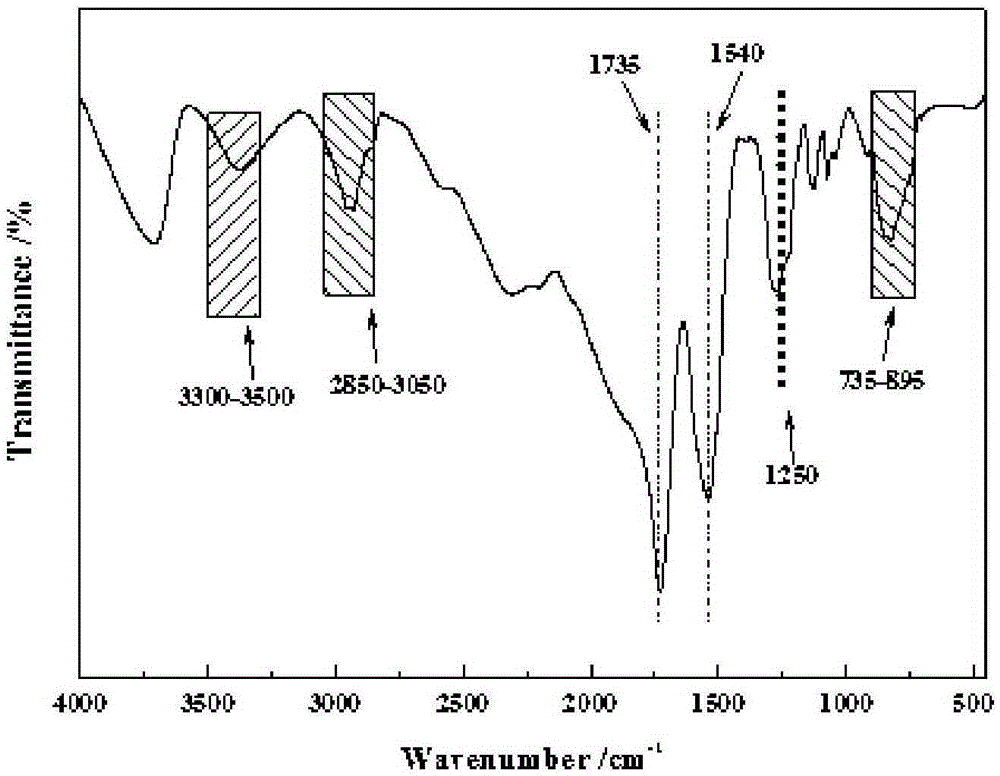

[0037] Poly-1,6-hexanediol phthalate (molecular weight 2000) 11.70g, isophorone diisocyanate 7.4g, dimethylol propionic acid 1.1g, 1,4-butanediol 0.6 g, 0.17g of trimethylolpropane and 1 drop of catalyst dibutyltin dilaurate (about 0.05g) are stirred evenly in a three-necked flask equipped with a reflux condenser and a thermometer, and the stirring speed is kept at about 60-100rpm, and the reaction is stirred at 40°C 1.5h, the temperature was raised to 80°C for 5h, the temperature was lowered to 40°C, 0.83g of triethylamine was added, and the reaction was carried out at 40°C for 20min. The product was stirred rapidly (the stirring speed was about 200-300 rpm), and 190 g of deionized water at 8° C. was added. Keep the stirring speed at 200-300rpm and mix for 10 minutes, add 0.3g of ethylenediamine as a chain extender to obtain a phthalic anhydride-based polyester polyol water-based polyurethane emulsion, and the solid content of the emulsion is about 10%. The emulsion was sali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com