Application of oxygen-nitrogen free radical group containing triphenylamine derivate polymer containing as electrochromic material

A free radical and triphenylamine technology, which is applied in the field of triphenylamine derivative polymers, can solve the problems of poor uniformity of film formation, increased production costs, and complex chemical preparation processes, achieving low cost, short response time, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

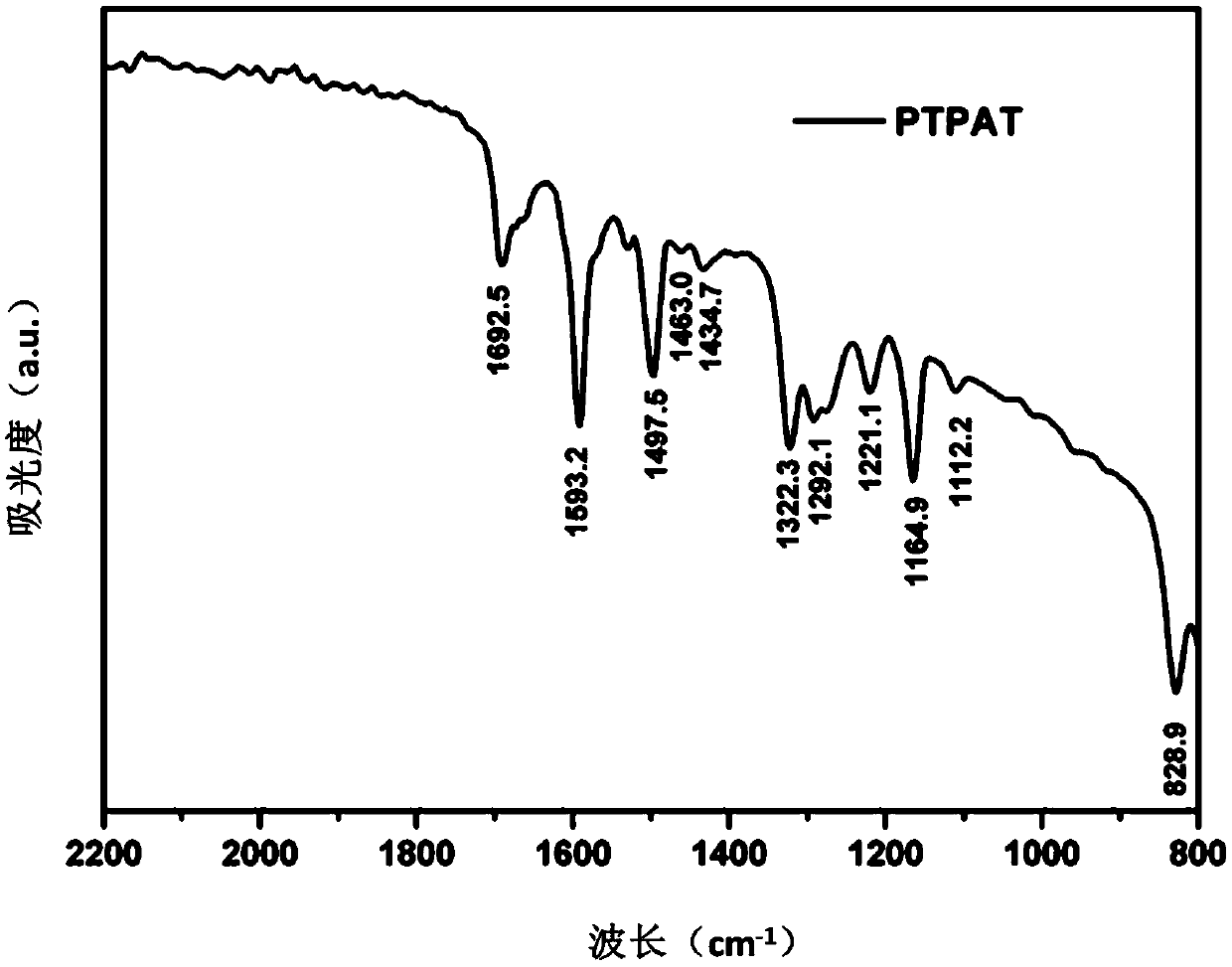

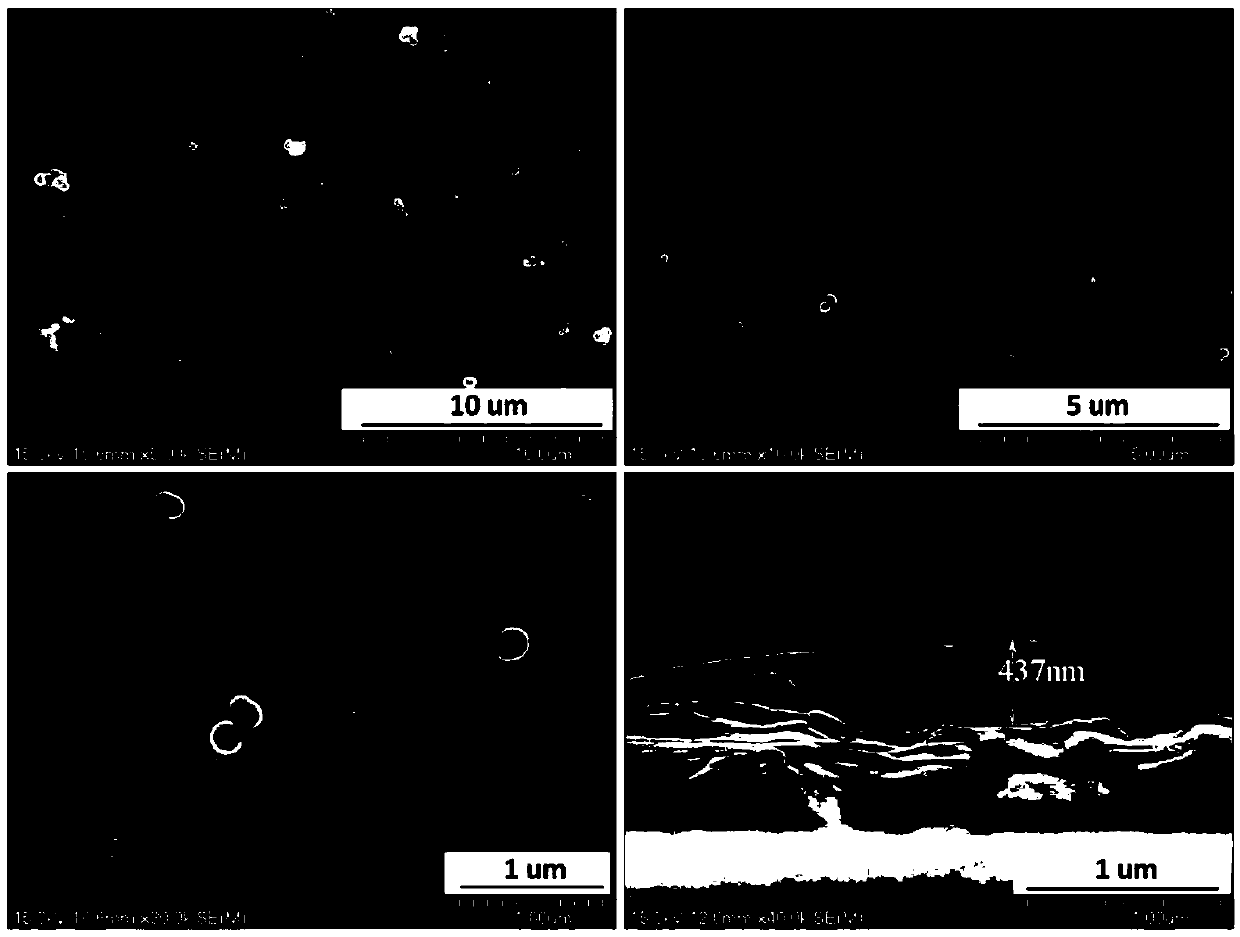

[0053] Embodiment 1: the electrochemical synthesis of PTPAT

[0054] (1) Synthesis of 4-diphenylaminobenzonitrile

[0055] Add 50 mL of anhydrous N,N-dimethylformamide (DMF) to a pre-dried 250 mL three-neck flask, followed by sodium hydride (1.5 g), and stir well to remove a large number of bubbles generated during the dissolution process. When no bubbles are generated, diphenylamine (III) (5.1 g) is added and the temperature is raised to 110° C., the reaction solution turns green tea green, then p-fluorobenzonitrile (IV) (4.5 g) is added, and the reaction solution turns dark red. in N 2 Under the protection of the reaction 12h to reach the end of the reaction. The crude reaction product was washed and extracted with dichloromethane and water, and the oil phase extract was dried, and then the solvent was removed by a rotary evaporator, and the remaining product after rotary evaporation was separated and purified by column chromatography. The stationary phase was 300 mesh sil...

Embodiment 2

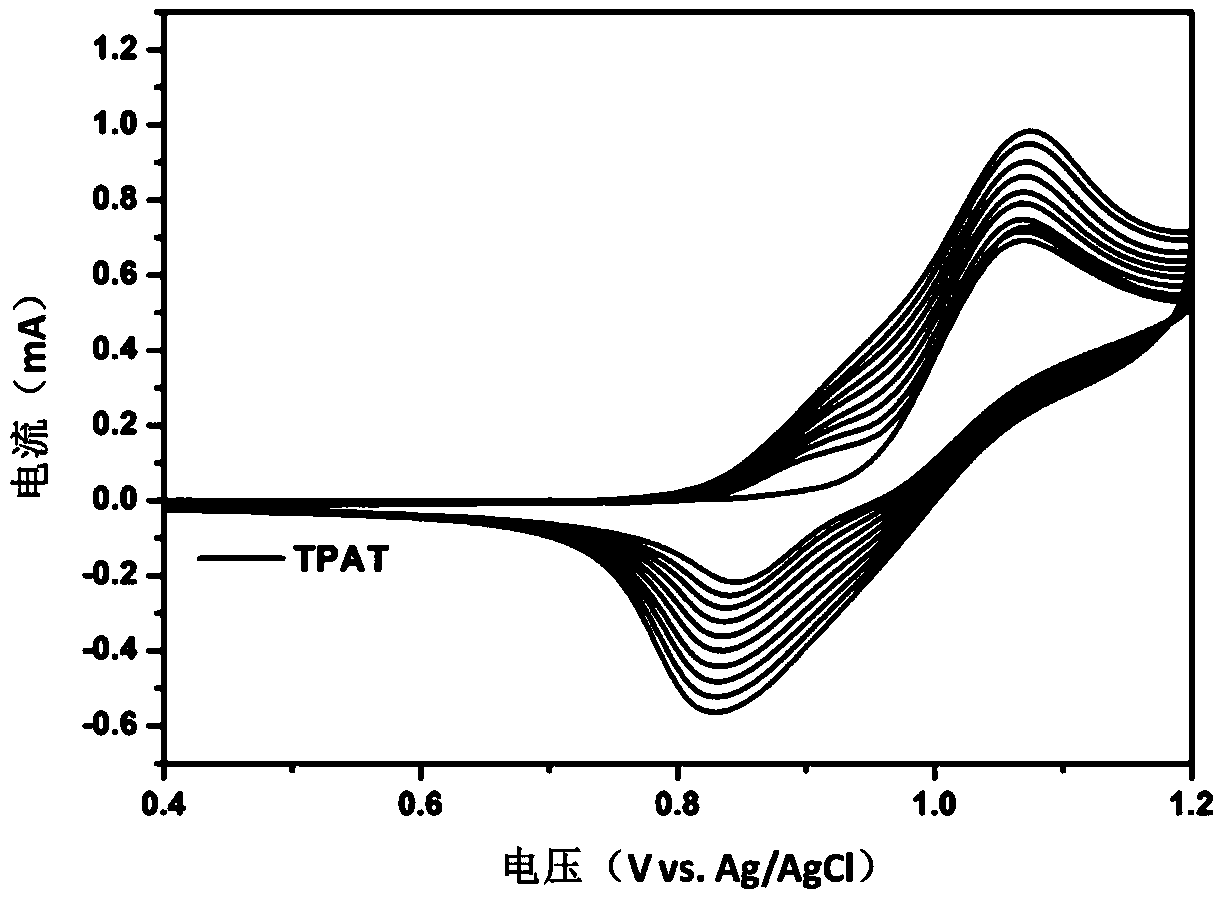

[0066] Example 2: Electrochromism of PTPAT in Acetonitrile

[0067] The PTPAT polymer thin film that is attached to the ITO glass prepared in embodiment 1 is put into three-electrode electrolytic cell, is dissolved with 10 in the cell -2 mol / LLiClO 4 / acetonitrile solution as the electrolytic solution, wherein the working electrode is ITO glass with PTPAT polymer film, the counter electrode is platinum wire, and the reference electrode is silver-silver chloride electrode. Cyclic voltammetry was used for scanning, the scanning voltage range was 0.4V-1.2V, the scanning speed was 100mV / s, and the scanning was performed for 300 cycles. It can be observed with the naked eye that the film changes from yellow to dark green as the voltage increases, and when the voltage decreases, the color turns back to yellow, and so on. The relationship between the redox peak on the cyclic voltammetry curve and the color of the polymer film was recorded. See Table 1:

[0068] Table 1 The relati...

Embodiment 3

[0070] Embodiment 3: the electrochromic response speed and contrast of PTPAT in acetonitrile The PTPAT polymer thin film that is attached on the ITO glass prepared in embodiment 1 is put into the three-electrode electrolytic cell, is dissolved with 10 -2 mol / LLiClO 4 / acetonitrile solution as the electrolytic solution, wherein the working electrode is ITO glass with PTPAT polymer film, the counter electrode is platinum wire, and the reference electrode is silver-silver chloride electrode. The combined technology of electrochemical workstation and ultraviolet spectrometer is adopted. The electrochemical workstation is set to multi-potential step method, the ultraviolet spectrum is set to ultraviolet absorption, and the scanning range is 1100-300nm. The final data obtained as Figure 5 as shown, Figure 5 It can be seen that under the condition of neutral state 0V, PTPAT has an absorption peak at 409nm, which is attributed to the π-π of the polymer main chain. * The characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com