Method for measuring content of free boron oxide in boron nitride

A boron nitride and boron oxide technology, applied in the chemical field, can solve the problems of high detection cost, complex maintenance and repair requirements, and high equipment cost, and achieve the effects of simple operation steps, low detection cost and accurate data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

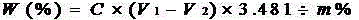

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a method for detecting the content of free boron oxide in boron nitride, which specifically includes the following steps:

[0024] Step 1, first use a drying oven to bake 5g of hexagonal boron nitride to constant weight; then weigh 1.0478g of the baked hexagonal boron nitride and place it in 5mL of dilute hydrochloric acid solution with a mass percentage of 20% Carry out acid leaching for 20 minutes to obtain acid leaching turbid solution; then place the acid leaching turbid solution on an electric furnace and heat and boil for 50 minutes, after cooling, filter and wash to obtain acid leaching filtrate, wherein the purpose of heating and boiling is to remove the Volatile components such as carbon dioxide in the acid leaching turbid solution.

[0025] Step 2, add 2mL indicator in the described acid leach filtrate of 180mL, wherein said indicator is by volume ratio be that the mass percent of 1:3:1 is 5% bromocresol green solution, methyl red solu...

Embodiment 2

[0030] This embodiment provides a method for detecting the content of free boron oxide in boron nitride. The specific steps are roughly the same as those in Example 1, except that:

[0031] The present embodiment is to measure the content of free boron oxide in the cubic boron nitride of 1.0396g;

[0032] Adopting 5mL mass percent in the described step 1 is that the dilute sulfuric acid solution of 30% carries out acid leaching to 1.0396g described cubic boron nitride;

[0033] In the said step 2, the dilute sulfuric acid solution with a mass percentage of 30% and the potassium hydroxide standard solution with a concentration of 2mol / L are used successively to neutralize and titrate the acid leaching filtrate, and then heated and boiled in an electric furnace for 20 minutes to obtain a boric acid mixture ;

[0034] In the step 3, the complex mixed solution of the potassium hydroxide standard solution with a concentration of 2mol / L is used to neutralize to present grayish blue...

Embodiment 3

[0038] This embodiment provides a method for detecting the content of free boron oxide in boron nitride. The specific steps are roughly the same as those in Example 1, except that:

[0039] In this embodiment, the content of free boron oxide in the boron nitride mixture composed of 1.0284g hexagonal boron nitride and cubic boron nitride is determined;

[0040] In the first step, 5 mL of dilute sulfuric acid solution with a volume ratio of 1:1 and a mass fraction of 30% is used for acid leaching the boron nitride mixture;

[0041] The content of free boron oxide in the hexagonal boron nitride detected in this embodiment is determined to be 0.15% by experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com