Recombined saccharomyces cerevisiae and construction method and application thereof

A technology for recombinant Saccharomyces cerevisiae and construction methods, applied in the direction of recombinant DNA technology, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of high price, long reaction time, low solubility, etc., and achieve mild transformation conditions and transformation The effect of high efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1p

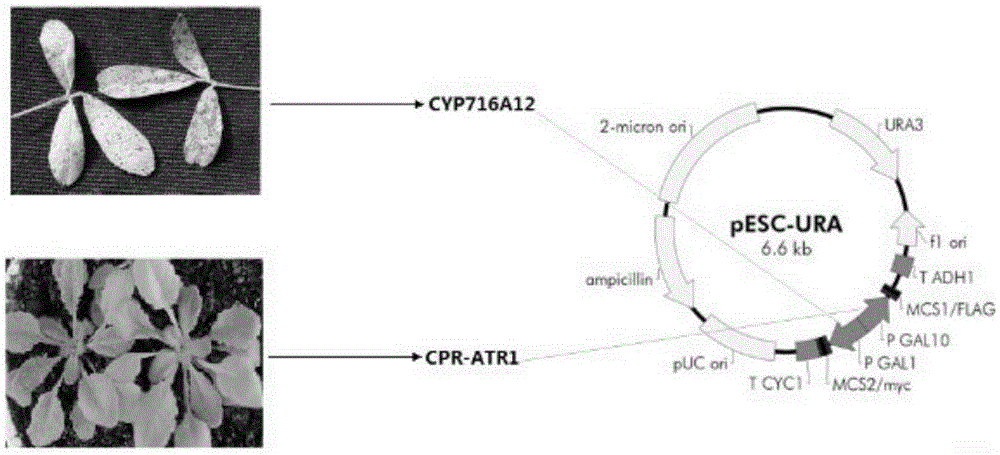

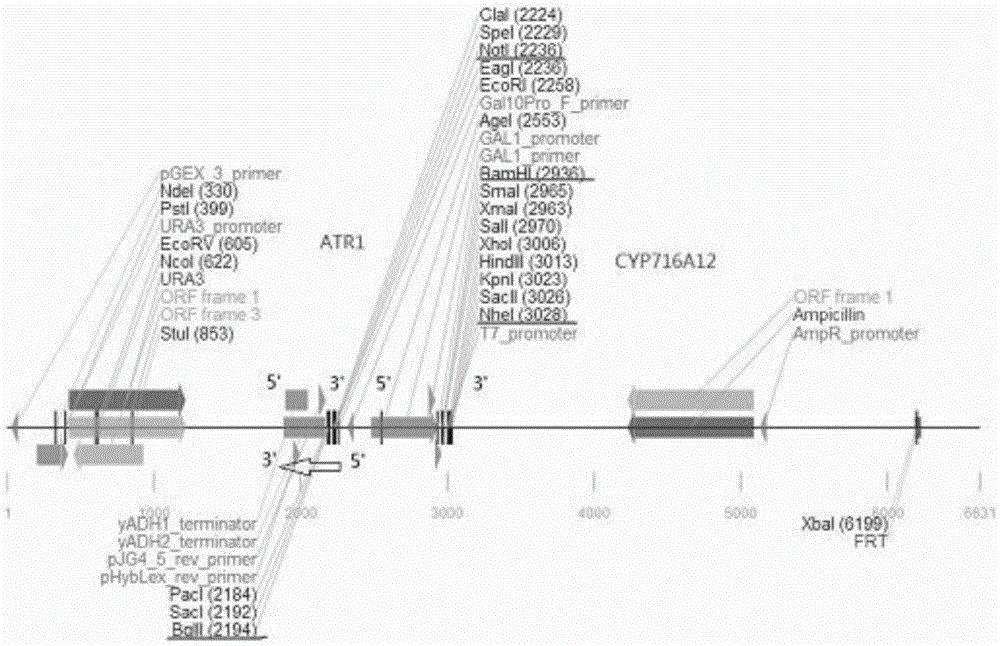

[0038] Embodiment 1 pESC-ura-CYP716A12-ATR1 plasmid construction

[0039] (1) Acquisition of CYP716A12 and ATR1 gene sequences

[0040] Using the total DNA from the four-week-old leaves of Medicago truncatula provided by Mr. Wang Yanzhang from the Institute of Plant Physiology and Ecology, Shanghai Institutes for Biological Sciences, Chinese Academy of Sciences, use primers C-F (see Table 1 for the primer sequence, the same below) and C-R to amplify CYP716A12 For the gene, the amplification conditions were: pre-denaturation at 95°C for 3 minutes; denaturation at 95°C for 10 s, annealing at 56°C for 10 s, extension at 72°C for 40 s (35 cycles); complete extension at 72°C for 10 min.

[0041] Total RNA (OMEGA, E.Z.N.Z.PlantRNAKit) was extracted from the leaves of Arabidopsis thaliana seedlings, and ATR1 gene (TaKaRa, PrimeScriptOneStepRT-PCRKitVer.2) was amplified by reverse transcription with primers A-F and A-R. The amplification conditions were: reverse transcription at 50°C fo...

Embodiment 2

[0049] Example 2 Construction of Recombinant Saccharomyces cerevisiae W303-1b

[0050] The pESC-ura-CYP716A12-ATR1 plasmid was introduced into Saccharomyces cerevisiae by the lithium acetate transformation method, and the SC-ura solid medium plate was spread, and the single colony grown was streaked and purified, and a single colony was selected, and the preliminary identification of the colony was positive by PCR. Afterwards, the liquid medium was used to expand the culture, and the plasmid was extracted for sequencing to confirm that the plasmid was introduced successfully.

[0051] Add 25% sterilized glycerin to the successfully constructed recombinant Saccharomyces cerevisiae liquid, and store in a -80°C refrigerator. The recombinant Saccharomyces cerevisiae is named Saccharomyces cerevisiae W303-1b, and was deposited in the China Center for Type Culture Collection (CCTCC) located in Wuhan University, with storage time: November 5, 2015, and storage number: CCTCC NO: M2015...

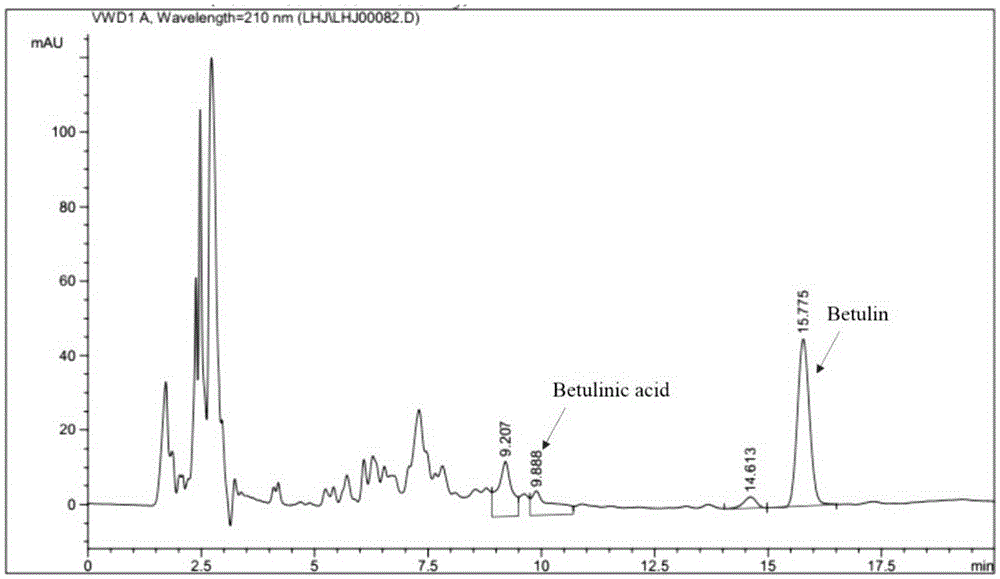

Embodiment 3

[0052] Example 3 Microsomal protein preparation

[0053] 100 μL of recombinant Saccharomyces cerevisiae W303-1b bacteria liquid was inserted into 10mL LYPAD (GLu), and cultured at 30°C and 180rpm for 20h; 6 Inoculate 50mLYPAD (GLu) at a seeding density of one / mL, and culture at 200rpm at 30°C for 12h. Centrifuge at 3000g for 5min to precipitate the bacteria, and wash twice with normal saline. OD2.01:20 was resuspended in 50mLYPAD (GAL), cultured at 16°C and 180rpm for 24h.

[0054] Centrifuge at 2000g for 10min, add 50mLTEK buffer to the cell pellet, and centrifuge at 6100g for 3min. The bacterial pellet was resuspended in 10 mL of extraction buffer. Divide into 2mL centrifuge tubes with appropriate amount of glass beads, vibrate at a frequency of 65Hz, and vibrate for 49s, and vibrate continuously for 3 times. After the samples were placed on ice for 5 min, vibration grinding was repeated three times. Centrifuge at 6100g for 15min, filter, add MgCl with a final concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com