Graphene single crystal and rapid growth method thereof

A graphene and single crystal technology, applied in the field of materials, can solve the problems of slow growth of graphene film, energy consumption and gas consumption, and reduce the nucleation density of graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

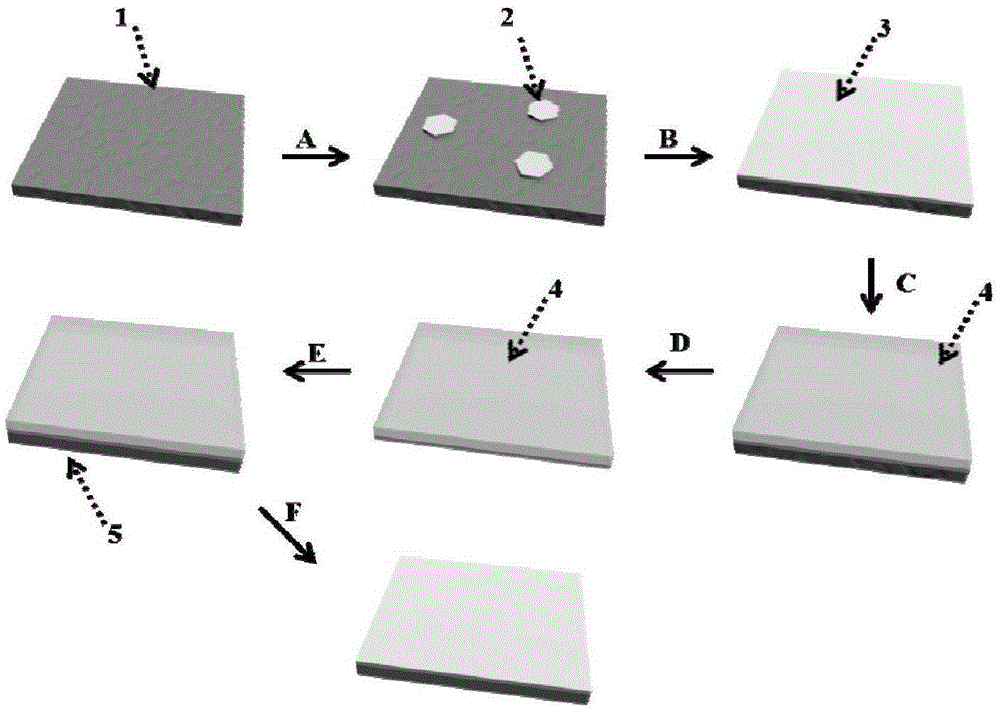

[0080] Embodiment 1, rapid preparation of large single crystal graphene

[0081] 1) Place copper foil (produced by AlfaAesar, with a purity of 99.8%, and a thickness of 25 μm) in a phosphoric acid glycol solution for electrochemical polishing. The concentration of phosphoric acid is 85%, and the volume ratio of phosphoric acid and glycol is 3:1. Density maintained at 30A / m 2 -100A / m 2 Between, the polishing time is about 30min. The polished copper foils were rinsed with deionized water and dried with nitrogen gas.

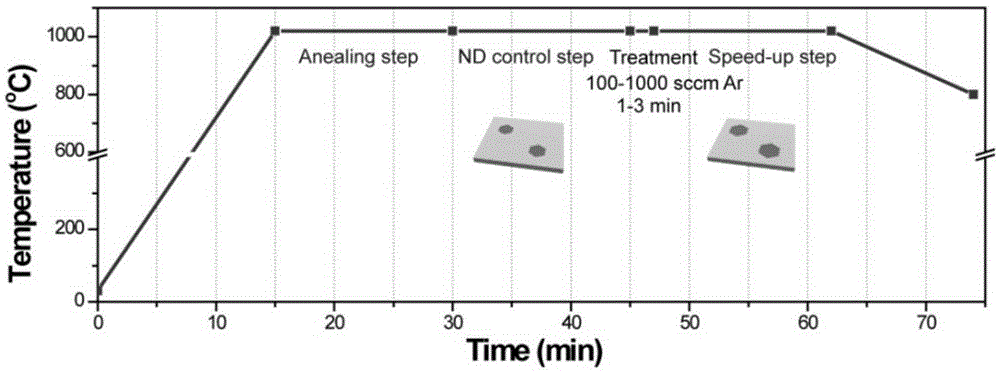

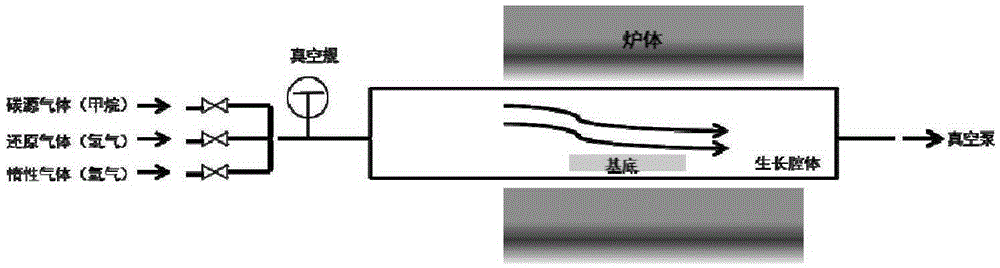

[0082] 2) Place the above-mentioned polished copper foil in a casing with magnetic control, and place the casing in a large quartz tube of a tube furnace, heat up to an annealing temperature of 1020° C. in 500 sccm of argon, and the system pressure It is 480Pa.

[0083] 3) After the temperature rises to 1020° C., 100 sccm of hydrogen gas is introduced, the system pressure is 100 Pa, and annealed in this atmosphere for 40 minutes to obtain an annealed copper foi...

Embodiment 2、 3

[0093] Embodiment 2, three-stage speed-up growth of large single-crystal graphene

[0094] Step 1) to step 6) are identical with step 1) to step 6) of embodiment 1;

[0095] 7) Keep the system at 1020°C, turn off the argon, feed 60sccm of hydrogen and 0.2sccm of methane into the system, and keep it for 15min for secondary growth. Under this condition, graphene can proceed along the graphene island in step 5) epitaxial growth.

[0096] 8) Cut off methane and hydrogen successively, and pass 100sccm of argon and oxygen mixture gas into the system, keep it for 20s for three passivation, rely on a small amount of oxygen in argon to passivate the copper foil again, reduce active sites, reduce Nucleation density.

[0097]9) Keep the system at 1020°C, turn off the argon gas, feed 20 sccm of hydrogen and 0.2 sccm of methane into the system, keep it for 15 minutes for three growths, and then use a magnet to drag the sleeve with copper foil from the high temperature area of the tube ...

Embodiment 3

[0103] Embodiment 3, prepare the thin film of large single crystal graphene splicing

[0104] Step 1) to step 6) are identical with step 1) to step 6) of embodiment 1;

[0105] 7) Keep the system at 1020° C., turn off the argon, and feed 60 sccm of hydrogen and 0.2 sccm of methane into the system for secondary growth. Under this condition, graphene can grow epitaxially along the graphene island in step 5), After growing for 200 minutes, use a magnet to pull the casing loaded with copper foil out of the high temperature zone, quickly lower the sample temperature to room temperature, and end the growth of the sample, that is, the intrinsic graphene spliced by large single crystal graphene loaded on the copper foil is obtained. Graphene film.

[0106] Take out the grown copper foil sample, and hang-coat PMMA ethyl lactate solution with a mass fraction of 4% on the surface of the sample at a speed of 2000rpm for 1min; dry the sample on a hot stage at 170°C; use 90W air The pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com