Compound type quaternary ammonium salt cation silicate mineral collecting agent and preparation method thereof

A technology of quaternary ammonium salt cations and silicate minerals, applied in solid separation, flotation, etc., can solve the problems of low recovery rate of concentrate, high content of silicate and phosphorus, low silicon content of ore, etc. Simple process, good environmental performance, and strong collection capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of collector: react tetradecyl tertiary amine with benzyl chloride at 95°C for 2 hours, then cool to 45°C, add fatty alcohol polyoxyethylene ether nonionic surface active agent accounting for 4% of tertiary amine mass Finally, add diesel oil accounting for 3% of the mass of tertiary amine, and stir evenly at 40°C for 10 minutes to obtain the collector of the present invention.

[0039] Under laboratory conditions, when the dosage is 200 g / ton, the results shown in Table 1-5 are obtained through the open-circuit test of one rough and two fine reverse flotation.

[0040] Table 1-5 embodiment 1 laboratory test result

[0041]

[0042] The result in the table 1-5 shows, the collector consumption of the present invention is 200 grams / ton, and when other two kinds of comparison agent consumptions are 250 grams / ton, reverse flotation collector developed by the present invention and tetradecyl Compared with trimethylammonium bromide and 817M (applied on site in ...

Embodiment 2

[0044] Collector preparation: react cetyl tertiary amine and benzyl chloride at 95°C for 2 hours, then cool to 45°C, add fatty alcohol polyoxyethylene ether nonionic surfactant accounting for 4% of tertiary amine mass, Finally, add diesel oil accounting for 3% of the mass of the tertiary amine, and stir evenly at 40°C for 10 minutes to obtain the collector of the present invention.

[0045] The test ore sample and the beneficiation process conditions are the same as those in Example 1, and the test results are shown in Table 1-6.

[0046] Table 1-6 embodiment 2 laboratory test result

[0047]

[0048] The results in table 1-6 show that the collector consumption of the present invention is 200 grams / ton, and when other two kinds of comparison agent consumptions are 250 grams / ton, the reverse flotation collector developed by the present invention and cetyl Compared with trimethylammonium bromide and 817M (Australian on-site application), the collector of the present inventio...

Embodiment 3~8

[0050] The test ore sample and the beneficiation process conditions are the same as those in Example 1, and the test results are shown in Table 1-7. The preparation process and steps are the same as in Example 2.

[0051] Table 1-7 The distribution ratio of each component in Examples 3 to 8 (parts by mass)

[0052]

[0053] Note: A-tetradecyl tertiary amine, B-pentadecyl tertiary amine, C-hexadecyl tertiary amine, D-heptadecyl tertiary amine.

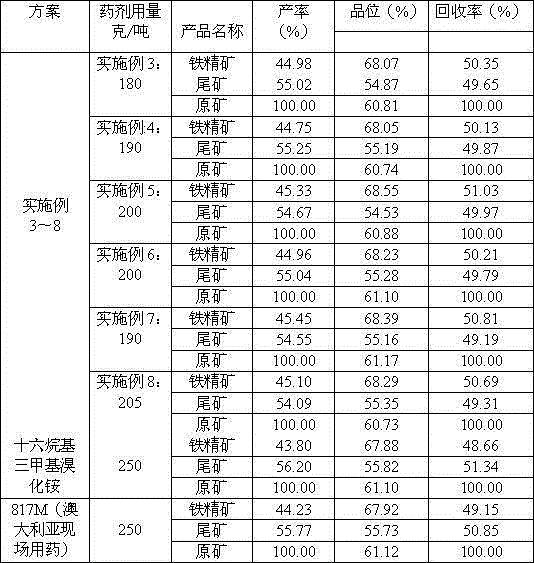

[0054] The test ore sample and the beneficiation process conditions are the same as those in Example 1, and the test results are shown in Table 1-8.

[0055] Table 1-8 Laboratory test results of Examples 3 to 8

[0056]

[0057] As can be seen from Table 1-8, the composite quaternary ammonium salt cationic silicate mineral collector prepared by the present invention is used for the flotation of microfine grain iron ore, and the iron concentrate grade and recovery rate obtained are all better than ten Hexaalkyltrimethylammoniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com