Preparation method of water-soluble polystyrene nanoparticles

A polystyrene nanometer and water-soluble technology, which is applied in the field of preparation of water-soluble polystyrene nanospheres, can solve the problems of cumbersome process, difficult post-processing, harsh reaction conditions of seed swelling method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

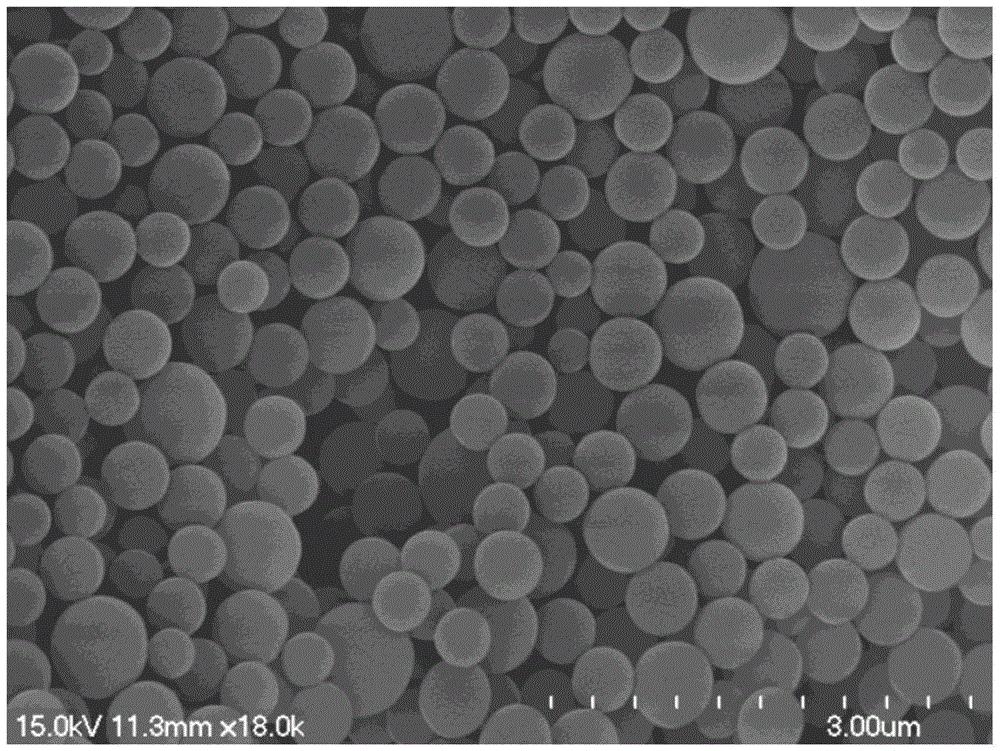

[0019] Dissolve 1 mL of styrene in 99 mL of deionized water, place it in an irradiation bottle, and blow it with nitrogen. Irradiate in a cobalt source with a radiation dose of 10KGy to obtain a 1% polystyrene nanoparticle solution with a particle size of about 500nm.

Embodiment 2

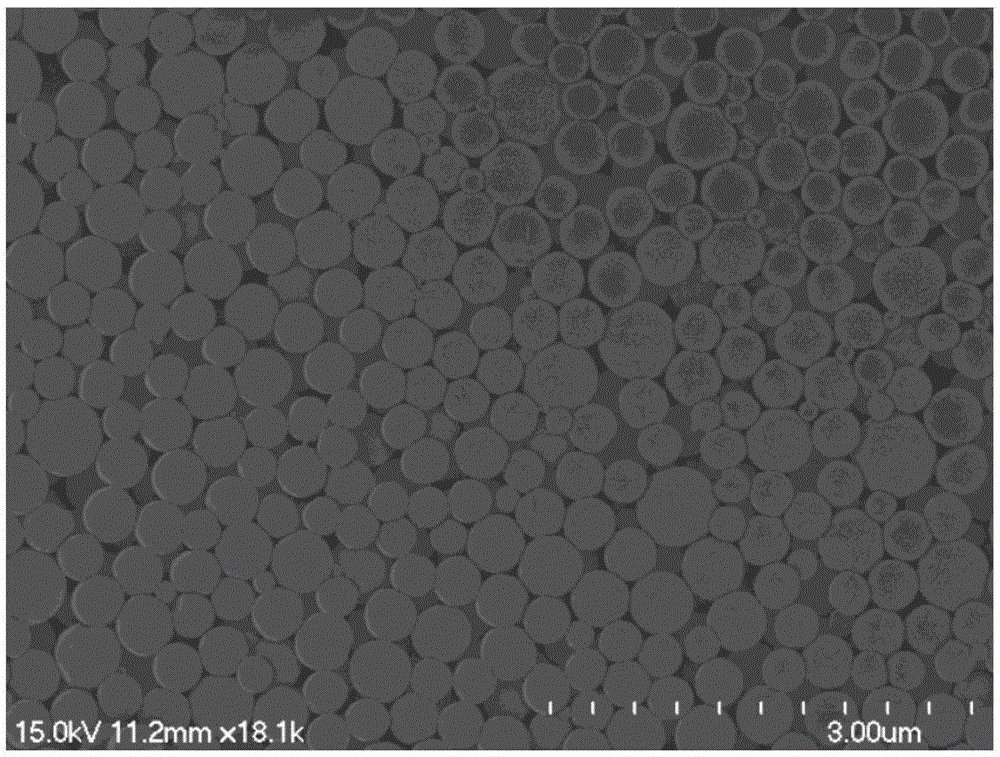

[0021] Dissolve 1 mL of styrene in 99 mL of deionized water, place it in an irradiation bottle, and blow it with nitrogen. Irradiate in a cobalt source with a radiation dose of 100KGy to obtain a 1% polystyrene nanoparticle solution with a particle size of about 10nm.

Embodiment 3

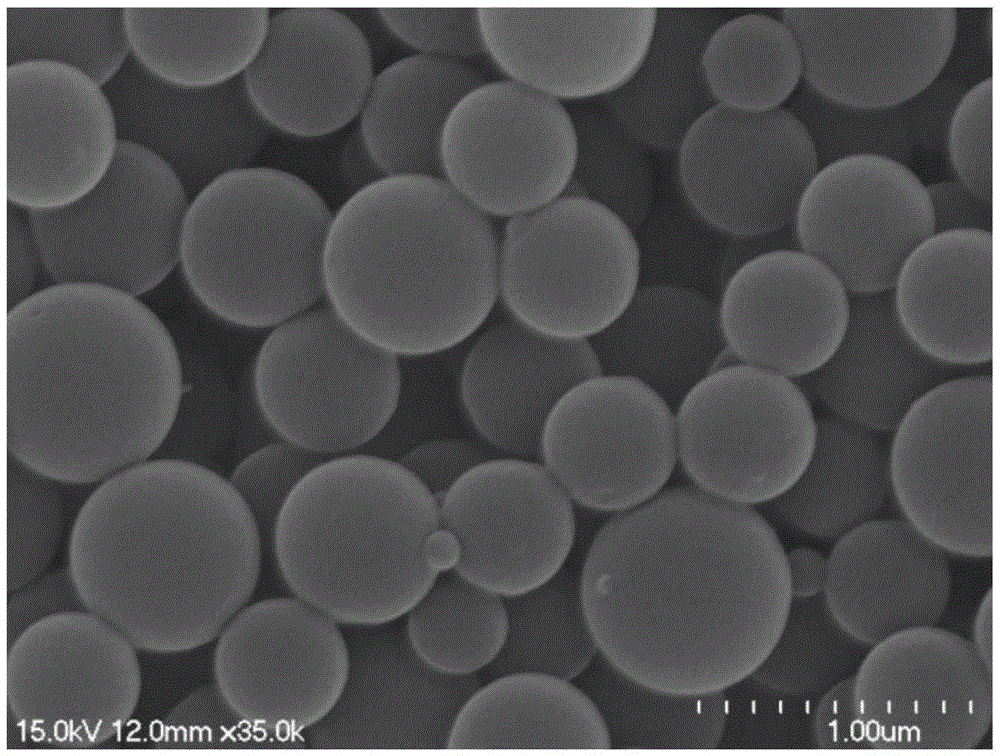

[0023] Dissolve 1 mL of styrene in 99 mL of deionized water, place it in an irradiation bottle, and blow it with nitrogen. Irradiate in a cobalt source with a radiation dose of 30KGy to obtain a 1% polystyrene nanoparticle solution with a particle size of about 20nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com