Gallium plating electroplating liquid and gallium film pulse electroplating method

A pulse electroplating and electroplating solution technology, applied in the field of electroplating, can solve the problems of high temperature operation, high cost consumption, high energy consumption, etc., and achieve the effects of good conductivity, wide use temperature and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

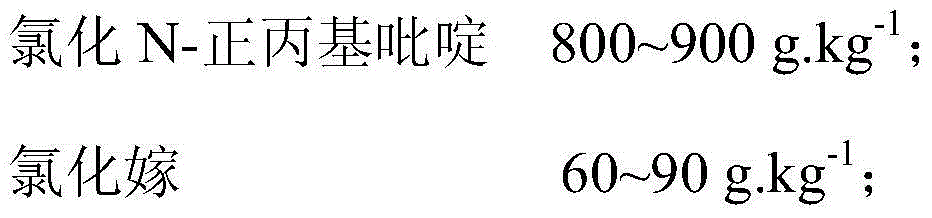

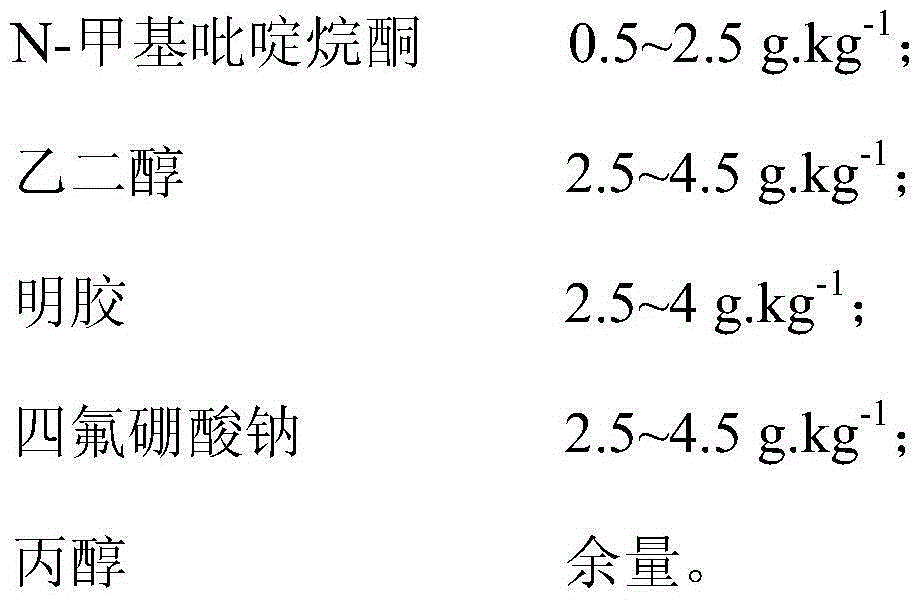

[0020] The gallium plating electroplating solution of the present embodiment is made up of the component of following concentration:

[0021]

[0022] The pulse electroplating method for preparing a gallium thin film using the gallium plating electroplating solution of this embodiment comprises the following steps:

[0023] a. Prepare the electroplating solution according to the proportion;

[0024] b. Pulse electroplating, the electroplating solution is injected into the electroplating equipment, and the copper sheet is used as the cathode and the pure gold plate is used as the anode for electroplating. The film deposited on the surface of the cathode copper sheet is a gallium film. The electroplating process conditions are, and the current density is 0.6A / dm 2 , The frequency is 500Hz, the duty ratio is 1:7, the temperature of the plating solution is 25°C, and the pH value is 7.5-11.5.

[0025] Wherein, the distance between the cathode and the anode is 5 cm, the power s...

Embodiment 2

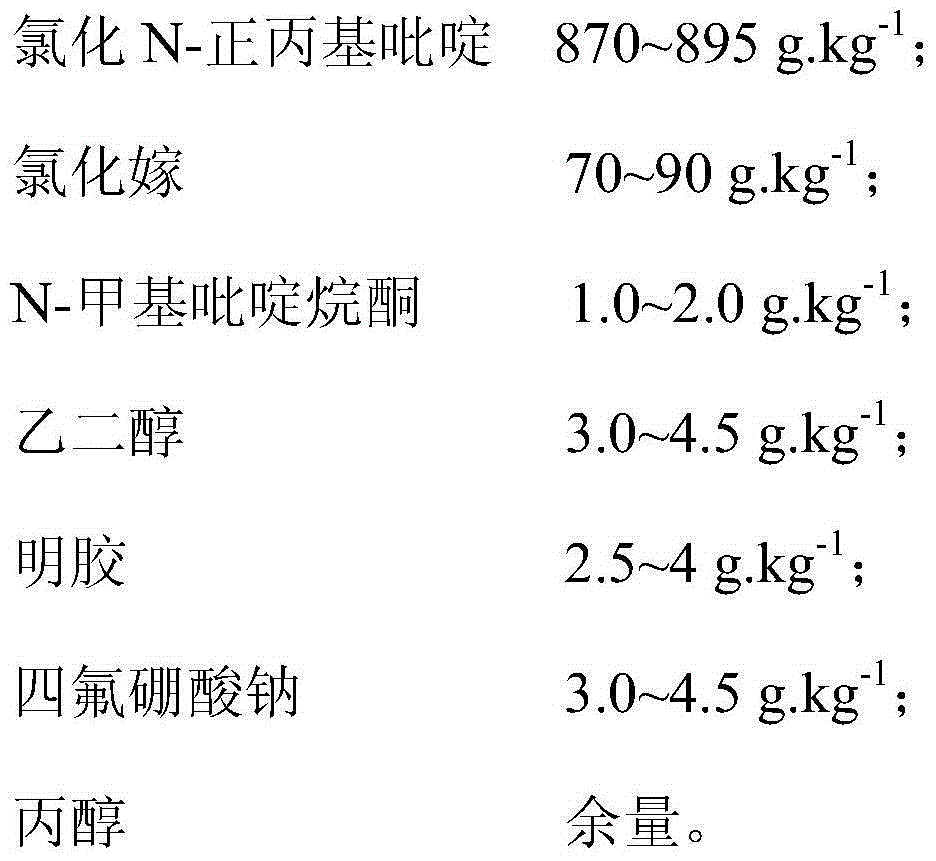

[0027] The gallium plating electroplating solution of the present embodiment is made up of the component of following concentration:

[0028]

[0029] The pulse electroplating method for preparing a gallium thin film using the gallium plating electroplating solution of this embodiment comprises the following steps:

[0030] a. Prepare the electroplating solution according to the proportion;

[0031] b. Pulse electroplating, the electroplating solution is injected into the electroplating equipment, and the copper sheet is used as the cathode and the pure gold plate is used as the anode for electroplating. The film deposited on the surface of the cathode copper sheet is a gallium film. The electroplating process conditions are, and the current density is 0.7A / dm 2 , The frequency is 600Hz, the duty ratio is 1:9, the temperature of the plating solution is 35°C, and the pH value is 7.5-11.5.

[0032] Wherein, the distance between the cathode and the anode is 6.5 cm, the power...

Embodiment 3

[0034]

[0035] The pulse electroplating method for preparing a gallium thin film using the gallium plating electroplating solution of this embodiment comprises the following steps:

[0036] a. Prepare the electroplating solution according to the proportion;

[0037] b. Pulse electroplating, the electroplating solution is injected into the electroplating equipment, and the copper sheet is used as the cathode and the pure gold plate is used as the anode for electroplating. The film deposited on the surface of the cathode copper sheet is a gallium film. The electroplating process conditions are, and the current density is 0.8A / dm 2 , The frequency is 700Hz, the duty ratio is 1:11, the temperature of the plating solution is 50°C, and the pH value is 7.5-11.5.

[0038] Wherein, the distance between the cathode and the anode is 8cm, the power supply for electroplating is a single-pulse electroplating power supply, and the mass percentage of gold in the anode is ≥99.99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com