Preparation method of pure titanium surface Ag/Sr co-doped TiO2 porous film

A porous film and co-doping technology, applied in the direction of surface reaction electrolytic coating, ion implantation plating, electrolytic coating, etc., can solve the problems of poor antibacterial performance, poor osseointegration of bioactive implants, etc., and achieve low cost and effective Good for adhesion and proliferation, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further illustrated by the following examples, but not limited to the following examples.

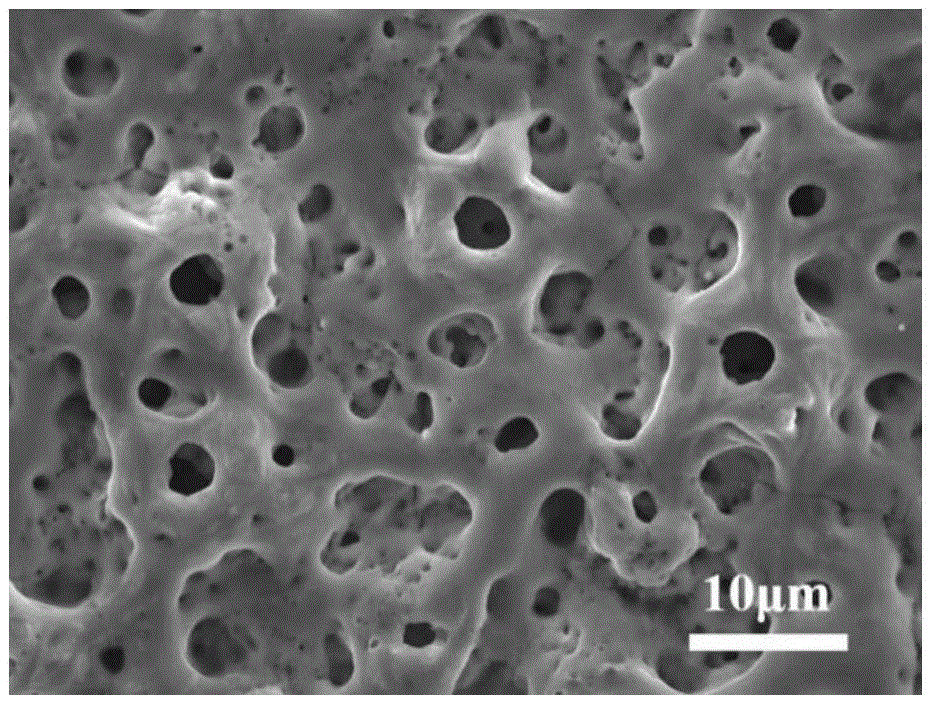

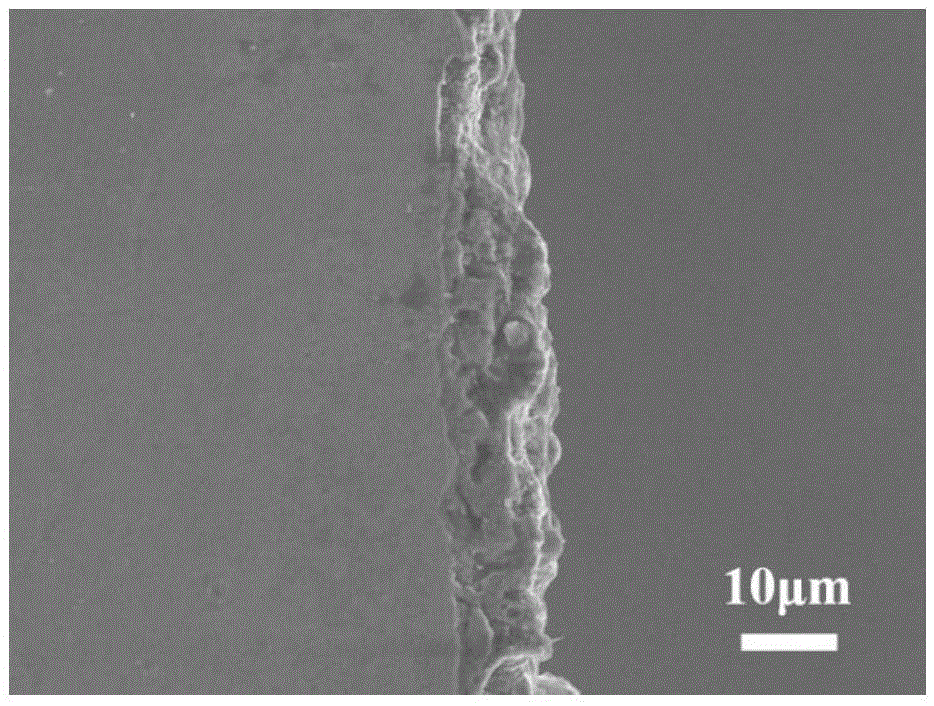

[0032] Implement a kind of pure titanium surface Ag / Sr co-doped TiO of the present invention 2 The preparation method of the porous film is to use the TiAg alloy target as the source in the magnetron sputtering coating equipment, and use the low-temperature plasma generated by the glow discharge to bombard the surface of the source to make the pre-plated metal elements flow from the source target The surface of the material is sputtered out, and a TiAg deposition layer is formed on the surface of pure titanium through transport deposition. Then put the sample with TiAg film deposited on the surface into the micro-arc oxidation electrolyte. Under the action of local high temperature and high pressure, the active elements Ca, P, and Sr in the electrolyte enter the surface of the sample through diffusion and electrophoresis. Formation of Ag / Sr co-doped TiO on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com