High-frequency soft-magnetic composite material and method of preparing magnetizer member with material

A technology of soft magnetic composite materials and magnetizers, which is applied in the fields of magnetism of inorganic materials, manufacturing of inductors/transformers/magnets, electrical components, etc., can solve problems such as performance not meeting performance indicators, complicated manufacturing process, and no application examples, etc., to achieve Excellent mechanical properties, reduced thermal shock damage, and reduced hysteresis loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

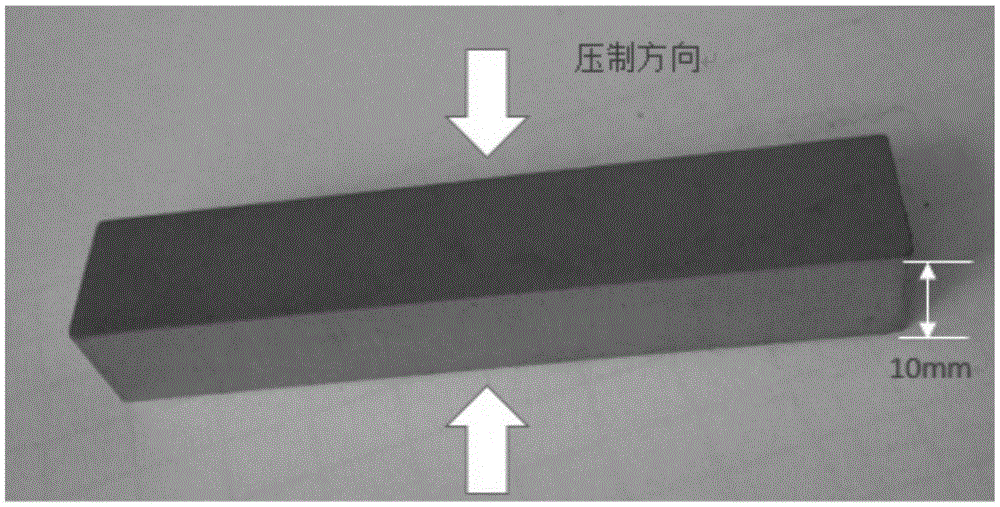

[0035] Embodiment 1, the manufacture of composite magnetic material and pressing magnetoconductor embryo body

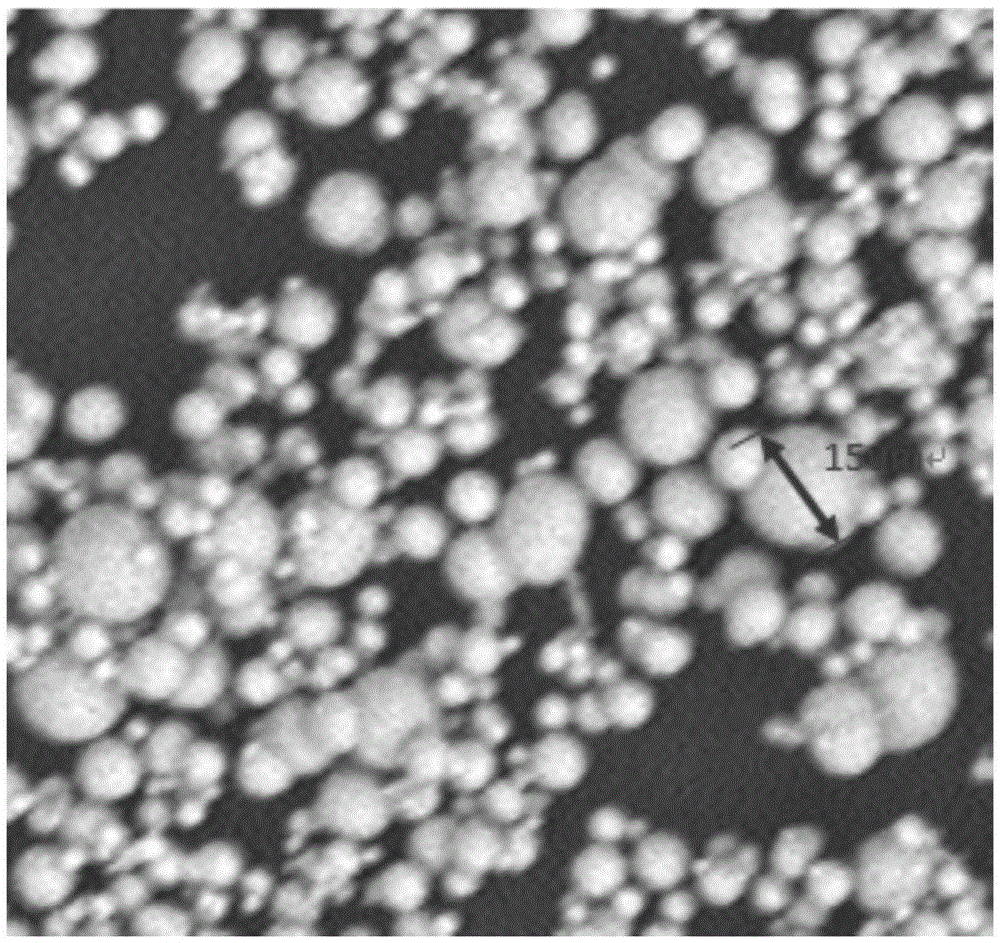

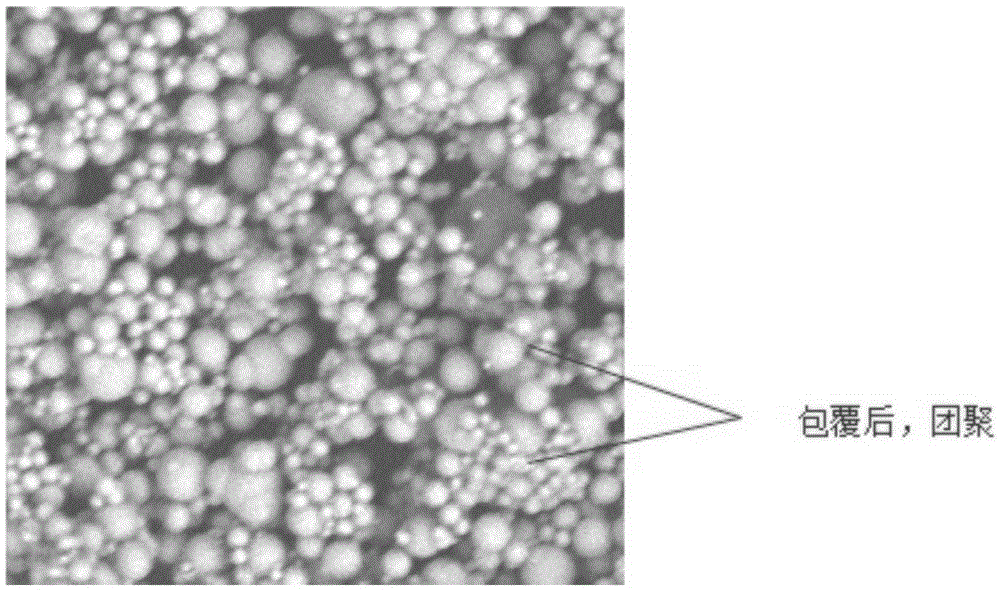

[0036](1) Choose carbonyl iron powder 1, with a purity of 99% and above, oblate spherical shape, a particle size of 5-15 μm, uniform particle size distribution, and relatively good shape consistency, see the attached figure 1 . The iron powder is first modified by coating with a silane coupling agent, the coupling agent is 3-aminopropyltriethoxysilane (KH550), and the addition amount is 0.8% of the mass ratio of the iron powder. Mix well and let dry. Modified iron powder, then add silicone resin (methylphenyl silicone resin) insulating agent, the amount added is 0.5-1.2% of the mass ratio of iron powder, in order to make the insulating agent disperse evenly and cover the same thickness, and at the same time Add an organic dispersing solvent (xylene) to the powder to dilute, and the amount of xylene used is twice that of methylphenyl silicone resin, that is, silicon...

Embodiment 2

[0043] Example 2. Manufacture of high magnetic permeability composite soft magnetic material, forming and heat treatment of magnetic conductor

[0044] (1) Select carbonyl iron powder 2, with a purity of 99% and above, the powder is mainly spherical, and the particle size is 15-35 μm. The iron powder is first coated with an amino-modified silane coupling agent (KH560), and the amount of iron powder added is 0.6% of the mass ratio. Mix well and let it dry. Modified iron powder, then add silicone resin insulating agent (epoxy modified silicone resin), the amount added is 1.6-2.0% of the mass ratio of iron powder, and at the same time dispersed with xylene solvent, the amount used is epoxy modified silicon Equivalent content of resin. Mix evenly, dry in an oven at 170°C for more than 2 hours, and the coating is completed. After testing, the thickness of the organic coating layer should be controlled below 0.5 μm and above 0.1 μm.

[0045] (2) Powder granulation. First disint...

Embodiment 3

[0049] Example 3, Manufacture of coated soft magnetic material and pressing high-frequency magnetizer

[0050] (1) Carbonyl iron powder 3 is selected, with a purity of more than 99.5%, oblate spherical shape, a particle size of 30-45 μm, and a uniform particle size distribution. The iron powder is firstly modified with an organic solvent whose coupling agent is vinyl tris(β-methoxyethoxy)silane (A-172), and the addition amount is 1.0% of the mass ratio of the iron powder. Mix well and let dry. Modified iron powder, then add silicone resin (phthalic acid modified silicone resin) insulating agent, the amount added is 0.6-1.2% of the mass ratio of iron powder, in order to make the insulating agent disperse evenly and cover the same thickness, at the same time Add an organic solvent (xylene) to dilute the iron powder, and the amount of xylene used is 1.5 times that of the phthalic acid-modified silicone resin. Mix evenly, and dry in an oven at 170°C for more than 2 hours. After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com