Method for preparing strong-hydrophilicity PET membrane

A water-based, strong affinity technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of affecting the hydrophilicity of the PET material surface, easy deposition and adsorption on the membrane surface, increasing the cost of sewage treatment, etc., to facilitate industrialization. The effect of low production, low price and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

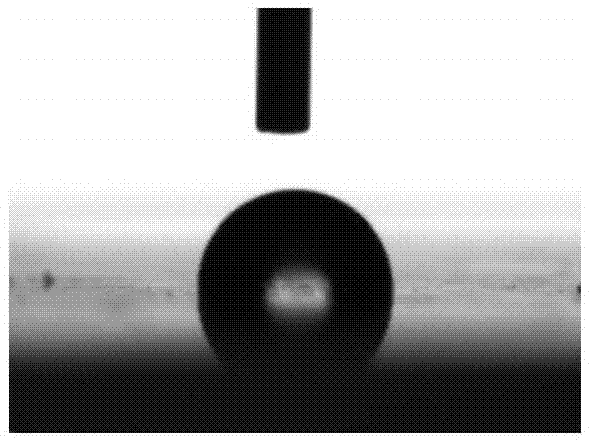

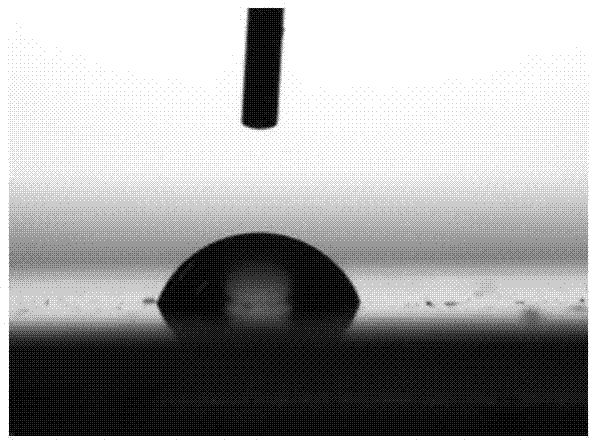

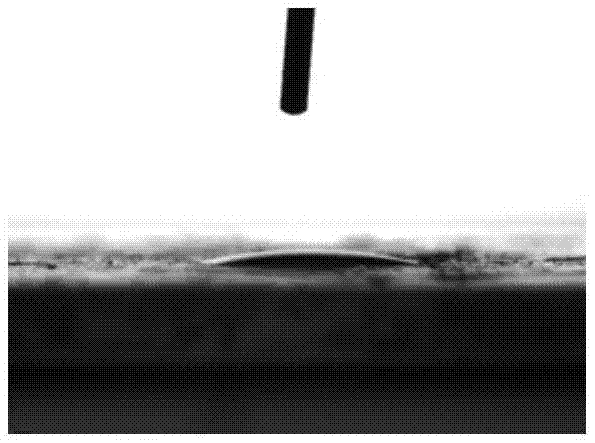

Image

Examples

Embodiment 1

[0027] a Take 0.1g of stannous chloride and put it into a beaker, add 20ml of acetone to completely dissolve the stannous chloride to obtain the acetone solution of stannous chloride, that is, the dopant.

[0028] b take nano-SiO 2 Put 6.00g into a beaker, add 100mL deionized water, and ultrasonically disperse for 1h. Then, 2.10 g of 3-aminopropyltrimethoxysilane was added under vigorous stirring, and the pH of the solution was adjusted to 5 with hydrochloric acid (the volume ratio of HCl to water was 1:1). Stir at 70° C. for 24 hours, then put it into a dialysis bag, and dialyze in deionized water at 4° C. for 48 hours to dialyze out small molecules. After the dialysis is completed, a modified nano-silica solution is obtained.

[0029] c Blend 10 mL of tetrachloroethane and 15.86 g of phenol to obtain a mixed solvent, add 0.4 g of PET particles to the mixed solvent, and raise the temperature to 130° C. until the PET particles dissolve. Add 0.48ml doping liquid to the soluti...

Embodiment 2

[0033] a Take 0.1g of stannous chloride and put it into a beaker, add 20ml of acetone to completely dissolve the stannous chloride to obtain the acetone solution of stannous chloride, that is, the dopant.

[0034] b take nano-SiO 2 Put 6.00g into a beaker, add 100mL deionized water, and ultrasonically disperse for 1h. Then, 2.10 g of 3-aminopropyltrimethoxysilane was added under vigorous stirring, and the pH of the solution was adjusted to 5 with hydrochloric acid (the volume ratio of HCl to water was 1:1). Stir at 70° C. for 24 hours, then put it into a dialysis bag, and dialyze in deionized water at 4° C. for 48 hours to dialyze out small molecules. After the dialysis is completed, a modified nano-silica solution is obtained.

[0035] c Blend 10 mL of tetrachloroethane and 15.86 g of phenol to obtain a mixed solvent, add 0.4 g of PET particles to the mixed solvent, and raise the temperature to 130° C. until the PET particles dissolve. Add 0.24ml doping liquid to the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com