A method of synthesizing a mesoporous MCM-22 molecular sieve and uses of the molecular sieve

A molecular sieve and mesoporous technology, applied in molecular sieve catalysts, chemical instruments and methods, hydrocarbons, etc., can solve problems such as unfavorable industrial production, cumbersome operation steps, etc., to improve production efficiency, good technical effects, and increase the amount of ethylene. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

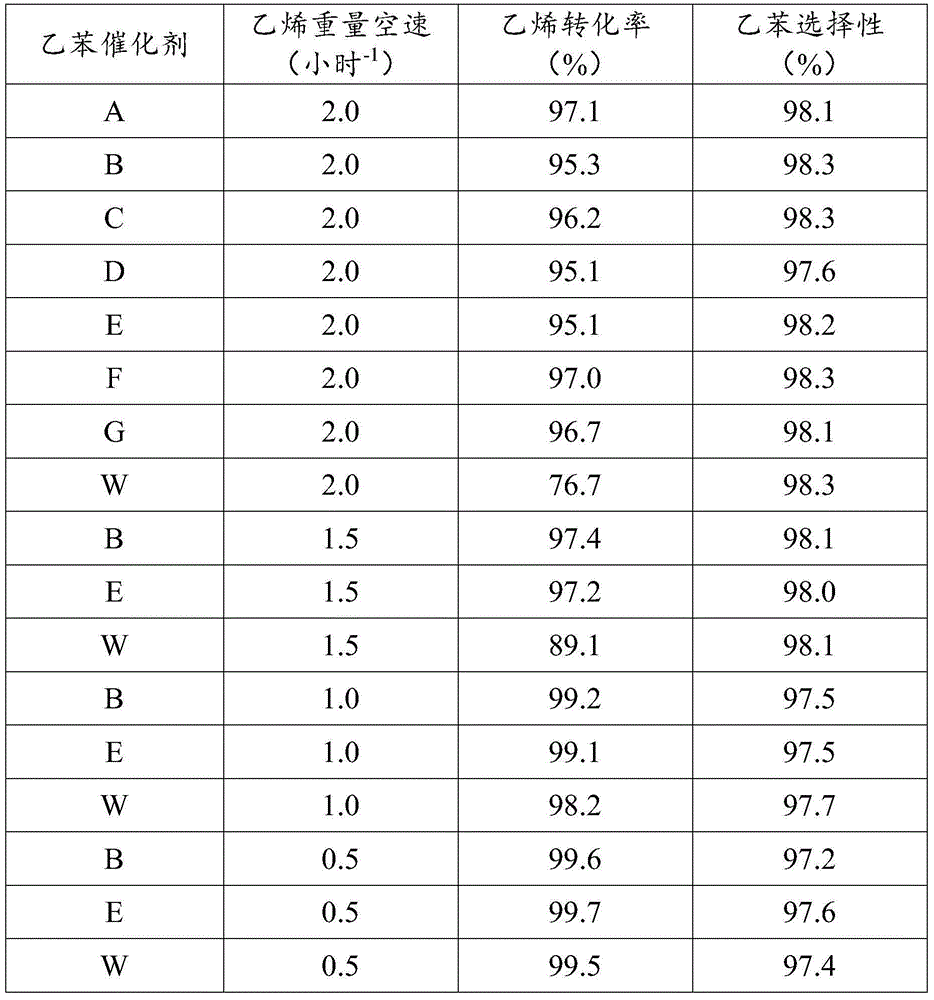

[0032] 22 g Al 2 (SO 4 ) 3 18H 2 O is dissolved in 365 grams of water, adding 12 grams of sodium hydroxide to make it dissolve, then adding 52 grams of hexamethyleneimine under stirring conditions, adding 225 grams of 40% silica sol, and finally adding 11 grams of carbon black, Mix the above reaction mixture evenly and crystallize at 140°C for 40 hours; finally, take out the above crystallized product, wash it, dry it, roast it, weigh 78 grams, knead it with 22 grams of alumina, extrude it, and bake it. The ethylbenzene catalyst A was obtained by drying and roasting, and the active component of the mesoporous MCM-22 molecular sieve had a weight content of 78%.

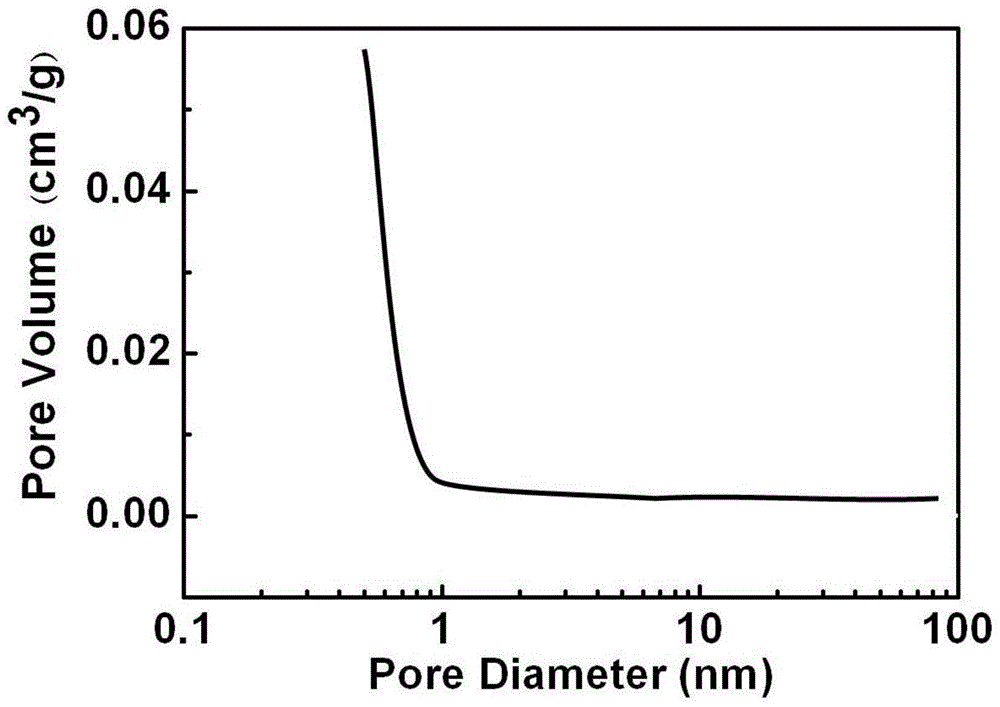

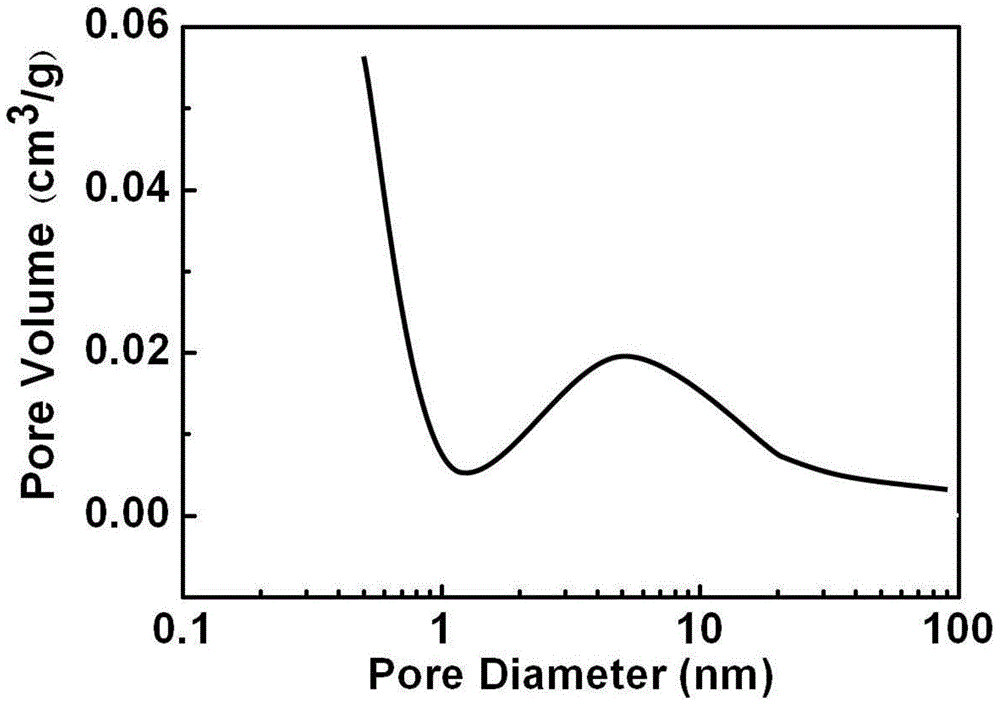

[0033] Among them, the pore size distribution of the crystallized product is shown in figure 2 shown. In terms of specific surface area percentage, the proportion of mesopores (pore diameter 2-100nm) is 73%, and the proportion of micropores (pore diameter 0.5-2nm) is 27%.

Embodiment 2

[0035] 40 g Al 2 (SO 4 ) 3 18H 2 O was dissolved in 460 grams of water, 42 grams of potassium hydroxide was added to dissolve it, then 38 grams of piperidine was added under stirring, 225 grams of 40% silica sol was added, and 27 grams of carbon black was finally added to make the above reaction mixture After mixing evenly, crystallize at 160°C for 70 hours; finally, take out the above-mentioned crystallized product, wash it, dry it, and roast it, weigh 62 grams, knead it with 38 grams of alumina, extrude it, dry it, and roast it. To obtain ethylbenzene catalyst B, the weight content of its active component mesoporous MCM-22 molecular sieve is 62%.

[0036] Among them, in terms of specific surface area percentage, the proportion of mesopores (2-100nm in diameter) is 56%, and the proportion of micropores (0.5-2nm in diameter) is 44%.

Embodiment 3

[0038] Dissolve 21 grams of sodium metaaluminate in 450 grams of water, add 12 grams of sodium hydroxide to dissolve it, then add 18 grams of piperidine and 9 grams of ethylenediamine under stirring, and then add 448 grams of ethyl orthosilicate , finally add 75 grams of carbon black, mix the above reaction mixture uniformly and then crystallize at 150°C for 55 hours; finally, take out the crystallized product, wash it with water, dry it, roast it, weigh 65 grams, and mix with 25 grams of The ethylbenzene catalyst C is obtained by kneading and extruding aluminum oxide, drying and roasting, and the active component mesoporous MCM-22 molecular sieve has a weight content of 65%.

[0039] Among them, in terms of specific surface area percentage, the proportion of mesopores (2-100nm in diameter) is 62%, and the proportion of micropores (0.5-2nm in diameter) is 38%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com