A kind of method of bisglyphosate mother liquor recycling

A technology of bisglyphosate mother and bisglyphosate, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, compounds of Group 5/15 elements of the periodic table, etc., can solve the problems of increasing crude product purification, frequent membrane clogging and damage, Problems such as short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

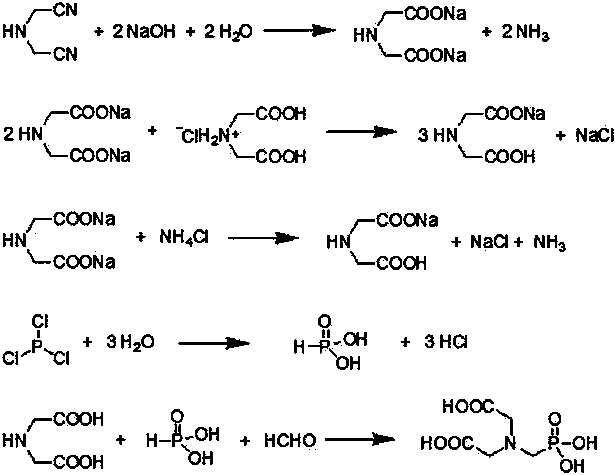

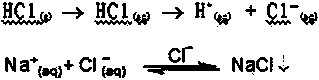

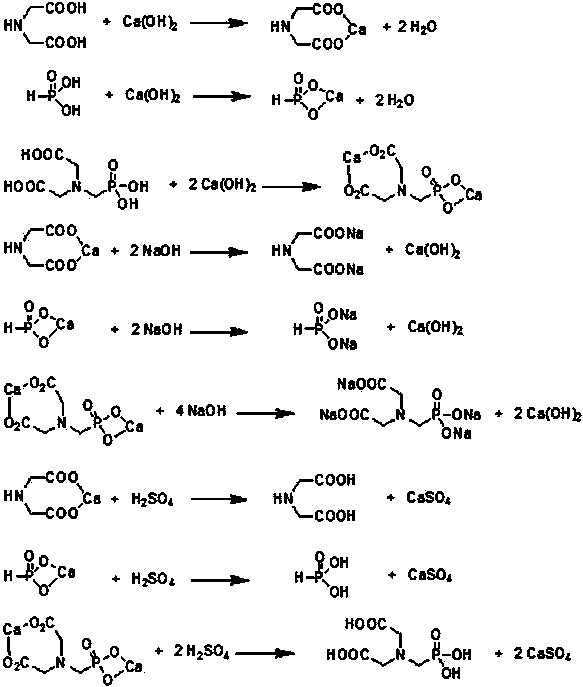

Method used

Image

Examples

Embodiment 1

[0069] Example 1 The acid hydrolysis of iminodiacetonitrile is applied mechanically to prepare the crude product of iminodiacetic acid hydrochloride.

[0070] Add 300 g of 32% hydrochloric acid and 50 g of water into a 500 mL four-necked flask, and preheat it to 60-80°C, add 50 g of 95% iminodiacetonitrile solid or its solution to the preheated hydrochloric acid at a uniform speed within 30 min After the addition, keep warm at 95-120°C for 30 minutes, cool down and crystallize and separate to obtain 101 g of iminodiacetic acid salt hydrochloride crude product, 295 g of acid hydrolysis mother liquor; add 50 g of water to the acid hydrolysis mother liquor and pass After 55 g of HCl gas, preheat to 60-80 °C, add 50 g of 95% iminodiacetonitrile solid or solution to the preheated acidolysis mother liquor with HCl gas at a uniform speed within 30 minutes, and the addition is completed at 95-120 Keep warm at ℃ for 30 minutes, cool down and crystallize and separate to obtain 151 g of ...

Embodiment 2

[0072] Example 2 Alkaline hydrolysis of iminodiacetonitrile and addition of iminodiacetate hydrochloride crude product condensation example

[0073] Mix 44 g of 96% sodium hydroxide and 150 g of water into a 500 mL four-necked flask, stir and maintain the temperature at 50-80°C, add 50 g of 95% iminodiacetonitrile solid or solution into the sodium hydroxide solution at a uniform speed , the feeding time is 0.5-1 h, after the feeding is completed, keep the temperature at 50-80°C for 30 min, and gradually raise the temperature of the alkaline solution to 100-110°C for deamination for about 1h. Add 38 g (IDA%=40.36%, acidity is 50% in terms of HCl) mixed iminodiacetic acid hydrochloride crude product in embodiment 1, partially acidify alkaline solution and continue heating deamination, deamination to steam pH= After 7-7.5, take samples to track and measure free ammonia and free NH 3 -N% = 0.03%, after deamination, add 60g of hydrochloric acid (37%) to continue acidification unti...

Embodiment 3

[0074] Example 3 Condensation of crude product of iminodiacetonitrile disodium salt by adding iminodiacetate hydrochloride

[0075] Take 200 g of the disodium salt feed liquid after the alkaline hydrolysis of iminodiacetonitrile in the workshop, in which the content of iminodiacetic acid is 25.09%; take 17.30 g of the crude product of diacid, in which the content of IDA is 48.38%, mix the two into 500 mL In a four-neck flask, gradually raise the temperature to 100-110°C for deamination, deamination to steam pH = 7-7.5, then take samples to track and measure free ammonia and free NH 3 -N% = 0.01%, after the deamination is completed, replenish water until the concentration of iminodiacetic acid is 27.5%, add hydrogen peroxide and activated carbon, and keep warm at 80-100°C for 30 minutes for decolorization, and the decolorized feed solution is at 60-70°C Slowly add 72.30 g of 98.26% phosphorus trichloride solution dropwise during heat preservation, and keep warm for 30 minutes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com